What is PLASTIC MOULD STEEL?

Plastic Mould Steels are characterised by good dimensional stability during heating, good polishability, high impact strength and good wear characteristics. This steel is an alloy of iron and nickel with a minimum of 10% carbon. It is used to make plastic moulds and dies, as well as castings for various purposes.

Plastic mould steel has a low coefficient of expansion, which makes it ideal for use in the cold environment of a plastic mould. It also has good machinability. The alloy has good weldability and can be easily worked without cracking due to its high strength.

Plastic mould steel is one of the most common materials used in manufacturing. This type of steel is commonly used to make products that are at risk of being damaged or destroyed by heat, such as food cans, drink bottles and food packaging.

Plastic mould steel is not just a good material for these products, but it can also be used for other purposes including: furniture construction, fencing, car parts and industrial components.

Plastic Mould Steel is an alloy of carbon, silicon, manganese and phosphorous. It has a high strength and ductility, with good fracture toughness properties. The addition of phosphorus gives it very good resistance to cold working. This material is usually used in complex machine parts where precision is required. It can be cast or forged.

Plastic Mould Steel is a type of steel that is used in many manufacturing processes. It is also used to make rubber and plastic moulds, which are then used to create products such as tools and toys. Plastic Mould Steel has many advantages over other types of steel. It can be formed into shapes that are difficult or impossible to achieve with other types of steel, and it can be used in high-temperature applications without being damaged by harsh conditions or chemicals.

Plastic moulds, mould frames for plastic moulds and pressure casting moulds and recipient sleeves.

Generally, few steel industries use these special steels from different mechanical engineering & tool manufacturers. And used for various large-size mirror plastic mould, precision plastic mould, like car accessories, home appliances, electronic equipment plastic mould.

Tempered and Pre-hardened is done to 1000Mpa. Whenever for plastic processing mould carrier large moulds ( over 400mm thickness) is used. Pre-hardened plastic mould steels are widely used for manufacturing mould for plastic.

High grade mould base for mirror surface & EDM requirement, rubber moulds, Injection moulds for bottle crates, TV sets housing fames, refrigerator doors, bucket and automobile related compartments, electrical and audio visual related compartments and etc.

PROPERTIES & CHARACTERISTICS:

- Wear Resistance

- Mould Frames

- Machine Tool Engineering

- Die Casting Industry

- Mould Parts

- Preform Dies

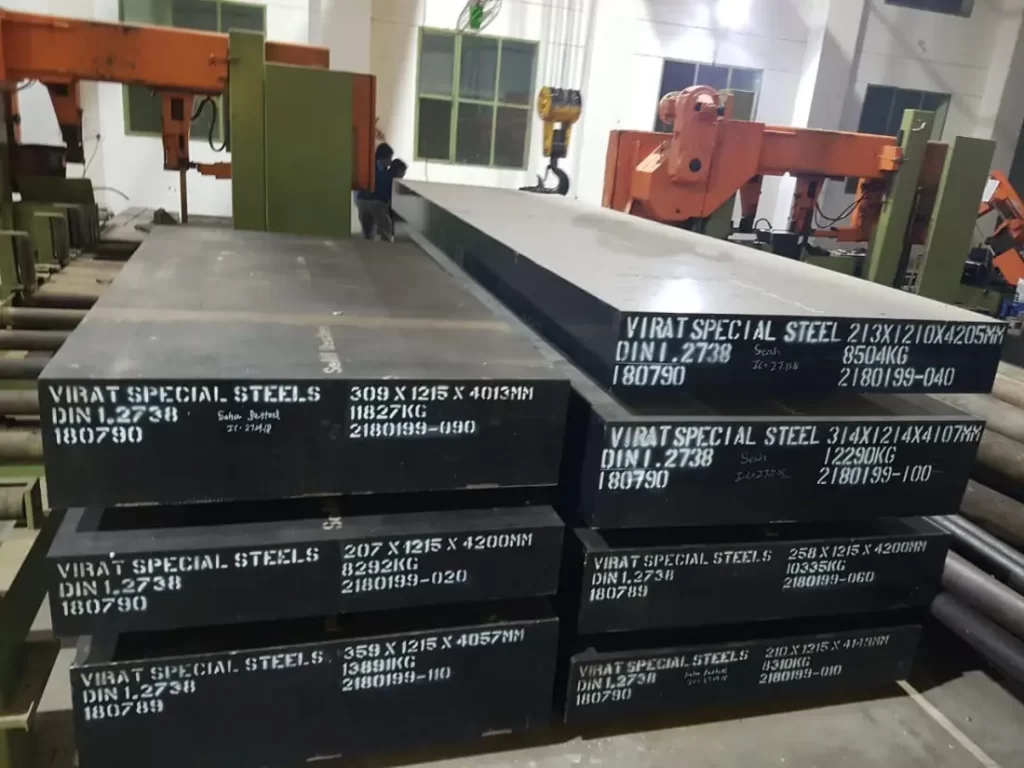

Virat Special Steels is the largest Supplier & Stockiest of Plastic Mould Steels.

Learn More:

https://www.viratsteels.com/plastic-mould-steel.html