AISI P20+Ni

now browsing by category

Exploring Tool and Die Steel Supplier in Vadodara, Gujarat?

Vadodara, or Baroda, is not just a city; it’s a testament to a rich cultural heritage intertwined with a robust industrial presence. Nestled on the banks of the Vishwamitri River, Vadodara stands as a proud bearer of the title ‘Sanskari Nagari’, reflecting its deep-rooted cultural ethos, and ‘Kala Nagari’, showcasing its vibrant art scene.

The city’s history is as grand as the Laxmi Vilas Palace, the majestic abode of the Maratha royal Gaekwad dynasty. This architectural marvel is not just a landmark; it’s a narrative of the city’s regal past. The Maharaja Sayajirao University of Baroda further adds to the city’s intellectual legacy, being one of the oldest and most esteemed educational institutions in India.

Vadodara’s economic landscape is equally impressive. It’s a nucleus of diverse industries, from engineering to IT, and biotechnology to pharmaceuticals. The city’s industrial prowess is exemplified by its flourishing tool and die steel sector, which serves as a backbone to various other industries, including automotive, aerospace, and medical.

Among the notable names in this sector is Virat Special Steels Pvt. Limited, a company that has carved a niche for itself by dealing in a wide array of specialized steels. Their commitment to quality and customer-centric services, such as material machining and metallurgical advice, is commendable. With state-of-the-art facilities in Gurugram and Ludhiana and a strong distribution network, Virat Special Steels stands as a testament to Vadodara’s industrial ingenuity.

When it comes to tool and die steel suppliers in Vadodara, there are several options to explore but Virat Special Steels is leader of this sector.

Product List:

- DIE STEEL ( HH 370 – 410 BHN ) DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Vadodara’s blend of cultural richness and industrial dynamism makes it a unique city with a multifaceted personality. Whether you’re drawn by its historical allure or its industrial capabilities, Vadodara is a city that promises to leave an indelible mark on its visitors.

For more information, you can explore here: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-vadodara/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎ +91 98140-21775

Exploring Tool and Die Steel Suppliers in Kanpur!

Kanpur, an industrial hub in northern India, is home to a myriad of businesses, including those in the manufacturing sector that require specialized materials such as tool and die steel. For companies operating in this domain, finding a reliable supplier is crucial. Virat Special Steels Pvt. Limited stands out as a prominent name in this niche market.

Virat Special Steels Pvt. Limited offers a comprehensive range of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their services extend beyond mere supply; they provide value-added services like material machining, cut pieces, and customized solutions tailored to the unique needs of their clients. With advanced facilities in Gurugram and Ludhiana, Virat Special Steels has woven a vast distribution network that spans the entirety of India, ensuring timely and efficient delivery of materials.

The company’s product lineup is diverse, catering to various industrial requirements:

- Die Steel (HH 370 – 410 BHN): This category includes robust grades such as DB6, DIN-1.2714, and AISI L6, known for their durability and resistance to wear.

- Hot Work Steels: These steels, including DIN 2343, 2344, AISI H11, and H13, are designed to withstand the rigors of high-temperature applications.

- Plastic Mould Steels: With options like DIN 2738, 2311, and AISI P20, these steels are ideal for crafting precise and intricate molds.

- High-Speed Steels: Grades such as DIN 3243, 3343, AISI M2, and M35 are featured here, suitable for applications requiring exceptional strength and speed.

- Cold Work Steels (HCHCr): This group comprises steels like DIN 2379, 2080, AISI D2, and D3, which are essential for tasks that demand high wear resistance.

- Alloy Steels, EN-Series, and more: A broad selection to meet the varied demands of the industry.

Quality assurance is a cornerstone of Virat Special Steels‘ operations. They employ rigorous testing methods, including chemical analysis, spectrometry, ultrasonic examinations, and hardness testing, to ensure that each steel grade meets the highest standards of quality and performance. This meticulous approach to quality control guarantees that clients receive the most suitable steel for their specific applications, optimizing both performance and cost.

Embracing the “Make In INDIA” initiative, Virat Special Steels is committed to providing competitive pricing, exceptional quality, and prompt service. This dedication positions them as a dependable choice for businesses seeking a “Make In INDIA” solution for their tool and die steel needs.

For manufacturers in Kanpur and beyond, Virat Special Steels Pvt. Limited represents a partnership that promises not just supply, but a commitment to quality, innovation, and customer satisfaction. Their extensive range of products and services ensures that every client’s unique requirements are met with precision and care, making them a go-to source for tool and die steel in the region.

Trusted Tool and Die Steel Supplier in Rohtak, Haryana!

Rohtak, a city within the National Capital Region of Delhi, stands as a testament to India’s rapid industrial growth. Established in 1976, this planned city has burgeoned into an industrial powerhouse, hosting a myriad of multinational corporations and startups across diverse sectors. With a modest population of approximately 23,000, Rohtak covers an area of 124 square kilometers and is strategically positioned in the Gurugram district of Haryana.

The city’s industrial landscape is particularly notable for its concentration of tool and die steel industries. Tool and die steel are specialized materials crafted to withstand the rigors of manufacturing tools, dies, molds, and other components essential for shaping and molding materials like metal, plastic, and rubber. These high-precision instruments are the backbone of manufacturing, enabling the production of intricate parts with consistency and quality.

Among the prominent players in Rohtak’s steel industry is Virat Special Steels Pvt. Limited. This company has carved a niche for itself by dealing in a comprehensive range of steels, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their commitment to quality is evident in their value-added services, which encompass material machining, provision of cut pieces, and the supply of tailor-made material solutions. Furthermore, Virat Special Steels Pvt. Limited extends metallurgical advice and ensures stringent quality assurance, underpinning their reputation as a reliable supplier.

The company’s state-of-the-art facilities in Gurugram and Ludhiana underscore their technological prowess, while a robust distribution network across India signifies their logistical competence. Such attributes not only enhance their standing in Rohtak’s industrial domain but also contribute significantly to the region’s economic vitality.

Here are some details about Virat Special Steels:

Company Overview: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made material.

Product Range:

- Die Steel (HH 370 – 410 BHN): This includes grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

Quality Assurance and Facilities:

Virat Special Steels boasts an impressive fully equipped quality assurance and process examination facility.

This includes:

- A laboratory for analyzing steel through chemical tests and spectrometry.

- Ultrasonic examination and hardness testing on Vickers, Rockwell, and Brinell scales.

These facilities allow clients to select the most appropriate type of steel for their specific applications and optimize costs in the long run.

Make In INDIA:

Virat Special Steels offers “Make In INDIA” products at competitive prices, great quality, and prompt servicing. They aim to increase and improve CPC (Cost Per Component) for their customers.

Rohtak’s evolution from a nascent city to an industrial hub is a narrative of vision, planning, and execution. The city’s tool and die steel sector is a microcosm of this transformation, reflecting the synergy between industrial expertise and infrastructural development. As Rohtak continues to expand and diversify, its role in India’s industrial narrative remains pivotal, promising a future where innovation and growth go hand in hand.

For more information, you can explore here:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-rohtak/

Any further queries feel free to contact us :

☎ +91 98140-21775 🌐https://www.viratsteels.com/

📬 info@viratsteels.com

Your Trusted DIN 2738 Steel Supplier of High-quality Steel in India!

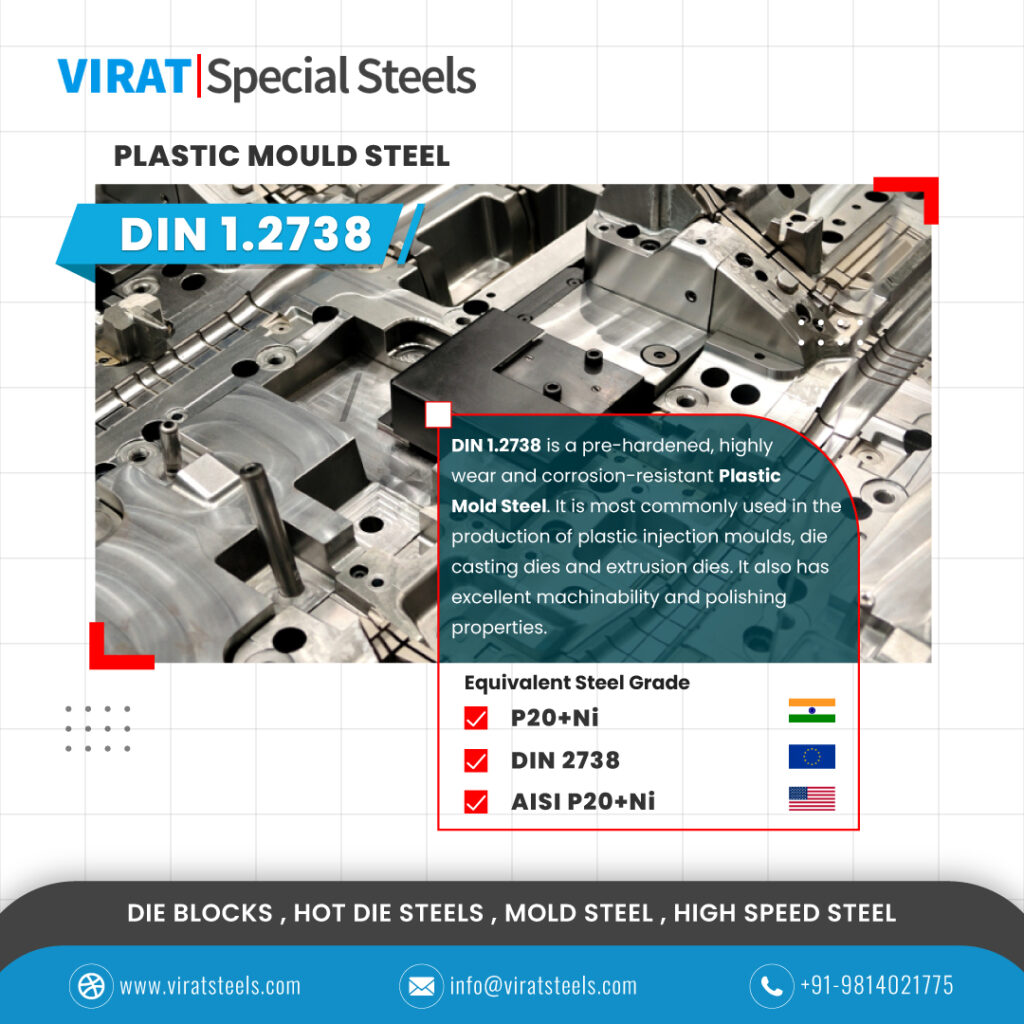

DIN 2738 is a premium mold steel that offers excellent polishability, wear resistance, and toughness, making it ideal for a wide range of tooling applications. DIN 2738 or P20+Ni is a specially designed mold steel with improved toughness and excellent machinability compared to standard P20 grades.

DIN 1.2738 is a widely used cold work steel, especially in the plastic mold industry. It is equivalent to P20+Ni and AISI P20+Ni tool steel. DIN 2738 steels have superior polishability compared to 1.2312 (AISI P20+S) and better machinability. To enhance the hardness and wearability of the mould surface material , it can be treated with nitrogenation and flame hardening. DIN 2738 steel is melted in an electrical furnace and refined using a VOD or DH equipment.

Chemical Composition:

Carbon (C): 0.35-0.45%, Manganese (Mn): 1.30-1.60%, Silicon (Si): 0.20-0.40%, Phosphorus (P): ≤ 0.030%, Sulfur (S): ≤ 0.030%, Chromium (Cr): 1.80-2.10%, Nickel (Ni): 0.90-1.20%, Molybdenum (Mo): 0.15-0.25%

Mechanical Properties:

Tensile Strength: 980-1180 MPa

Yield Strength: ≥ 800 MPa

Elongation: ≥ 15%

Hardness: 280-325 HB

Physical Properties:

Density: DIN 2738 and P20+Ni have a density of approximately 7.85 g/cm³.

Thermal Conductivity: The thermal conductivity of these steels is around 30-35 W/(m·K).

Specific Heat Capacity: The specific heat capacity is about 460-480 J/(kg·K).

Thermal Expansion: The linear coefficient of thermal expansion is approximately 11-12 x 10^-6 /K.

Application:

DIN 2738 is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

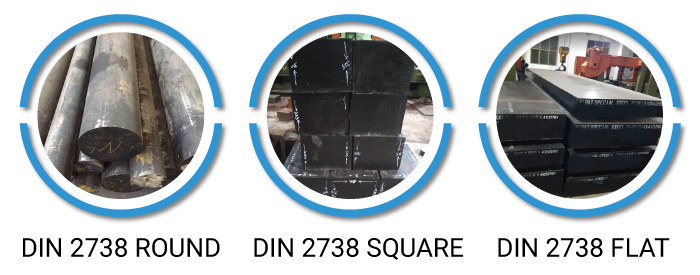

At Virat Special Steels, we provide DIN 2738 in round bar and flat bar blocks in different sizes and conditions to meet your specific requirements. Our team of experts is ready to assist you with any queries you have about DIN 2738 steel.

Learn more: https://www.viratsteels.com/din-2738.html

Contact us today to buy the best quality DIN 2738 steel for your tooling needs!

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com/

📬 info@viratsteels.com

Are you looking for top-quality tools, die, and mold steel in India?

Look no further! … We offer a wide selection of highest quality steel to meet your needs.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

VIRAT SPECIAL STEEL is leading brand in this segment, established 6 Decades before as an Importer, Exporter, Stockiest, Distributor and Supplier for Tool & Alloy Steels products in India.

We are dealing in a wide range of Tool and Alloy Steels segment products which include Cold Work Tool Steels, Hot Work Tool Steels, Die Block Steels, Alloy Steels, and Plastic Mold Steels. Our company stocks best in class products, which are wear and tear resistant and have dimensional accuracy.

Product List

- HOT WORK STEEL ( HH 370 – 410 BHN ) DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Are you looking for PLASTIC MOULD STEEL in India?

Plastic mould steels are widely used for manufacturing mould for plastic.

Get in touch with us today to place your requirement!

DIN 2738 #PlasticMouldSteel, The equivalent grade P20+Ni | DIN 2738 | AISI P20+Ni …

DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making moulds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish.

Also the specialized steels that have been created for plastic moulding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity. DIN 1.2738 Steels are low Carbon consisting of Carbon between 0.35 to 0.45%

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of DIN 2738 steel in flat, square and round bar. We provide steel in all sizes as your requirements.

Learn more:

https://www.viratsteels.com/p20ni.html

For more information Contact us:

info@viratsteels.com, +91-9814021775

Tool and Die Steel Supplier, Stuckist in Delhi NCR

Owing to environmental considerations, the city of Delhi, India, which is also a Union territory of some 20 million people, has seen much manufacturing activity moving out. It still continues with immense construction activity and as a thriving trading hub. Also Delhi is well connected to major industrial centers in the region; has an abundance of established suppliers for every commodity that includes steel and so, it is a convenient place to do business. Special steels continue to be in demand in its steel markets.

Both the engineering sector and steel traders in Delhi should consider getting in touch with Virat Special Steels, Gurgaon (Haryana) India – who is one of India’s top Tool & Die Steel suppliers. Also Stockists of Mould Steel, they can, with a little notice supply just about every grade of special steel that exists.

The following grades of steel are available with them on an ex-stock basis:

- DIE BLOCKS (DIN-1.2714)

- PLASTIC MOULD STEELS (P-20 / 2738)

- CHIPPER KNIVES STEELS

- HOT DIE STEELS (H-11,H-13 / 2343, 2344)

- HIGH SPEED STEELS (M-2, M-35, T-1)

- HIGH CARBON HIGH CHROMIUM STEELS (D-2, D-3 / 2080, 2379)

- ALLOY STEELS, EN-SERIES

They can also arrange for the following:

AFNOR Z 200 C 12; DIN 1.2080; UNI X 21O Cr 13 KU; JIS SKD1; B.S. BD 3;

ASTM A681; FED QQT570; SAE J437; SAE J438 and any other niche steel.

Virat Special Steels Private Limited, also have their steel yards and works in Gurgaon (Haryana) India. They maintain an inventory of special steels exceeding 3500 tonnes; and in their works, they operate 21 bimetal horizontal and vertical band saw cutting machines with capacity upto 2500 mm x 1100mm, their own machining shop, 20 magnetic lifts with capability of handling loads of upto 5 tonnes, 14 overhead lifting cranes that can handle loads of upto 20 tonnes, and fork lift trucks and all other required paraphernalia for immediately servicing customer orders in suitable sizes.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

At par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Both users and traders in Delhi will find more information on them at sites: www.viratsteels.com and info@viratsteels.com. or on mobile number +91-98140 21775.

Looking for the best quality Tool Steel, Die and Mold Steels Supplier for your engineering works!

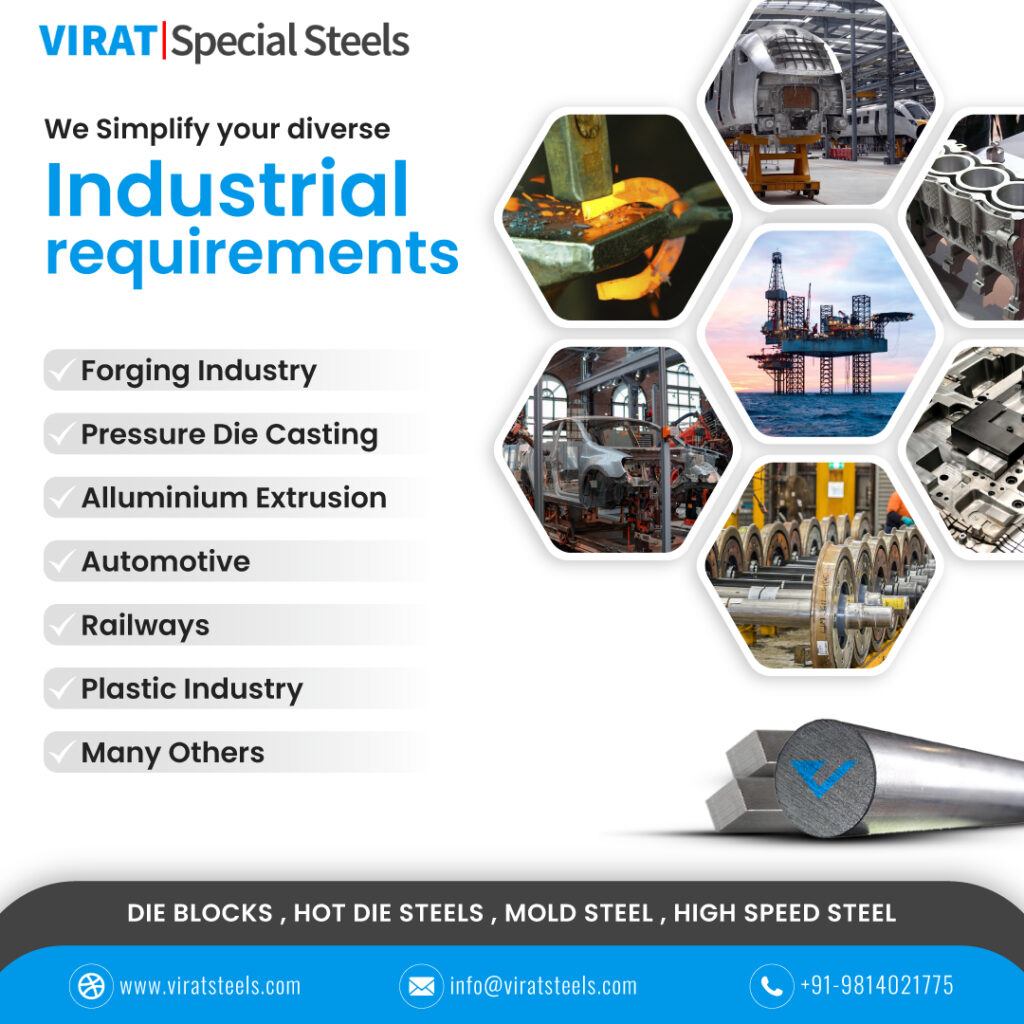

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry – Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions – In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: – Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry – Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: – Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry – Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: – DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways – They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas – Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stockist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes – Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter – Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

Feel free to contact us :

Corporate Office, #Gurgaon

Administrative Office, #Ludhiana

Email: info@viratsteels.com.

or Call us: 098140 21775

Plastic Mold Steels P20+Ni | DIN 2738 | AISI P20+Ni

DIN 2738 which is applicable for large & small plastic mold dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Up setter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making molds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish. Also the specialized steels that have been created for plastic molding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity.

Steel properties as given below, however, have to be optimally matched to the specific application and these are:

- Degree of purity

- Polishability

- Uniformity of hardness and microstructure

- Wear resistance

- Temperature resistance

- Machinability

- Toughness and hardness

- Thermal conductivity

The Nickel component contributes uniform hardness and structure, improves machinability and a polish that is easy to maintain.

This makes 1.2738 mold steel the ideal material for relatively low temperature applications such as die casting dies and injection molds, synthetic plastic molds dies, and especially for large plastic molds that are easily stressed at their core. They are also ideal for hydroforming tools. DIN 1.2738 is suitable for nitriding and chrome plating.

It is the preferred material for molds shaping plastic products such as automobile bumpers and TV shells. And also for molds for rubber products that are based on both hard rubber (PS) and ultra-hardened rubber (ABS). It is excellent in its processing performance, easy cutting and imparting finish to the end product. It resists electrical corrosion.

It is most cost effective when used for high-volume plastic molding such as TV set bodies, laptop bodies, plastic parts for home appliances and automotive parts and any such where finish is important.

As Virat Special Steels inform us, DIN 1.2738 tool steel is usually supplied as pre-hardened/quenched and tempered to 280 – 320 HB hardness. Still, after machining if the need arises, they can be annealed by first heating to 710°C and after the temperature gap between core and surface has narrowed to 740 °C for about 2 to 5 hours; followed by cooling slowly at the rate of 10 to 20 °C per hour to about 600 °C before further air cooling.

Hardening is conducted in the temperature range of 840-870°C to be followed by immediate quenching in oil/hot bath/air to a temperature between 180 to 220°C. Hardness after quenching is around 52 HRC.

Two rounds of tempering are required immediately after such hardening and the heating to tempering temperature must be gradual. Higher temperatures result in steel with lower hardness values (700°C results in an HRc of barely 30 while tempering at 250°C will result in HRc of 50). The duration of tempering at the chosen temperature should correspond to 1 hour per 20 mm of thickness.

They are usually supplied as Round Bar of diameter ranging from 20mm to 1000mm or as Plate or Block of thickness ranging from 12-500mm x width 200-2000mm. Generally black on the surface, they can be customized for clients in Roughly Machined, Peeled or Turned condition.

The Leading Company VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stuckist of P20+Ni | DIN 2738 | AISI P20+Ni

Learn more:

https://www.viratsteels.com/p20ni.html

For more information Contact us:

info@viratsteels.com, +91-9814021775