H13

now browsing by category

Versatility of H13 Tool Steel in India’s Manufacturing Sector!

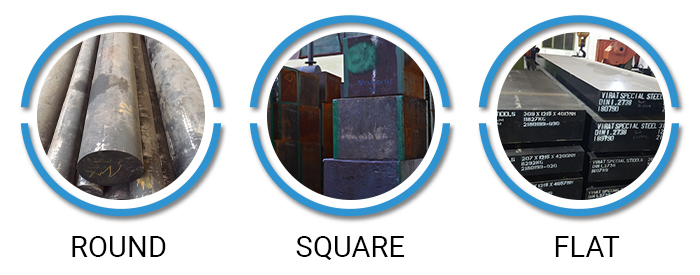

India’s manufacturing sector is experiencing a surge in quality and efficiency, thanks in part to the availability of superior materials like H13 tool steel. Known for its robustness and versatility, H13 tool steel has become a material of choice for various industrial applications. Virat Special Steels, a leading stockist and supplier of H13 tool steel in India, offers a comprehensive range of this premium material in various forms, including flat, square, and round bars, catering to diverse size requirements with precision.

Chemical Composition and Properties:

H13 tool steel is an alloy composed of Chromium, Molybdenum, Vanadium, and Carbon. This unique blend endows it with exceptional toughness, strength, and heat resistance, making it an ideal candidate for high-temperature applications. Its chemical composition is meticulously balanced to provide the best possible performance in challenging environments.

Mechanical and Physical Advantages:

The mechanical properties of H13 steel, such as high hardness, good toughness, and excellent wear resistance, make it suitable for demanding applications like die casting and plastic mold tools. Its physical properties, including a density of 7.8g/cm³, a melting point of 1427°C, and thermal conductivity of 23.1 W/m°C, further enhance its utility in manufacturing processes that require materials to withstand extreme conditions.

Global Equivalents and Accessibility:

H13 tool steel aligns with several international standards, making it equivalent to AISI H13, DIN 1.2344, JIS SKD61, and GB 4Cr5MoSiV1. This global recognition underscores its quality and adaptability, ensuring that manufacturers in India have access to a world-class product.

Virat Special Steels is at the forefront of supplying H13 tool steel, providing expert consultation and tailored solutions for industrial needs. Whether it’s for flat, square, or round bar shapes, their team is equipped to handle inquiries and deliver the right solution for any project.

The integration of H13 tool steel into India’s manufacturing sector signifies a step towards higher standards of production and a commitment to excellence. As industries continue to evolve, materials like H13 tool steel will play a pivotal role in shaping the future of manufacturing in India and beyond.

For more information or to consult with the Virat Special Steels team, reach out and discover how H13 tool steel can benefit your manufacturing processes.

Contact us today to learn more!

https://www.viratsteels.com/h13.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎+91 98140-21775

Is H13 Tool Steel better than M2 Tool Steel?

H13 tool steel and M2 tool steel are two prominent members of the tool steel family, each offering unique characteristics and suitability for specific applications.

H13 is a chromium-based hot-work tool steel, possess notable amounts of chromium, molybdenum, and vanadium in its composition. This blend provides exceptional toughness, making it an excellent choice for applications requiring durability in high-temperature environments such as die casting and forging.

On the other hand, M2, often referred to as high-speed steel, is a tungsten-molybdenum high-speed tool steel. With significant tungsten and molybdenum content, along with other elements like chromium and vanadium, M2 exhibits remarkable hardness and an ability to maintain its cutting edge even at elevated temperatures. This quality renders it ideal for cutting tools like: drills, taps, and milling cutters that demand endurance in high-speed cutting operations.

In its hardened state, H13 steel shows greater fracture toughness compared to M2 steel, while the M2 possesses higher hardness.

If you need more information or advice , please explore with Virat Special Steels , a leading supplier of tool steels in India and abroad can provide you with high-quality #H13 and #M2 steels in various forms and sizes, as well as heat treatment and machining services.

If you’re looking to purchase H13 and #M2 steels or have specific questions about their products, it’s best to directly visit their official website or contact them for details.

Give us a call today at 98140-21775 and visit our website : www.viratsteels.com to learn more about our products, service and more .

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us :

🌐https://viratsteels.com 📨 info@viratsteels.com 📞 +91 098140-21775

Sourcing Special Steels Supplier in Punjab?

Ranked by the World Bank as the best city in India to do business, Ludhiana has become the business hub of North India.

Ludhiana’s prosperity is reflected in glitzy malls and many flyovers; the result of great industrial activity. It is Asia’s largest centre for bicycle manufacturing producing more than 50% of 10 million India’s bicycles sold every year; and home for globally recognized bicycle brands – Hero and Avon. Ludhiana also produces 60% of India’s tractor parts along with large volumes of auto and two-wheeler parts and supplies such to renowned international companies like Germany’s BMW and Mercedes-Benz.

Additionally, the city manufactures domestic sewing machines, hand tools and industrial equipment. It has a thriving small-scale sector producing every type of industrial and other goods, from machine and auto parts, to household appliances, hosiery, apparel, and garments. Ludhiana even has its own stock exchange. Building and construction is ongoing – new flyovers, malls, housing and an International Airport for Punjab on the anvil.

Ludhiana is well connected to all major industrial cities of Punjab such as Jalandhar, Patiala, Moga, Chandigarh and Bhatinda; as well as Himachal, J&K and other parts of the country.

Special Steels are the core of all manufacturing be it making knives, or cutting and shearing equipment, or dies for thousands of different processes. And so, Ludhiana is the operating hub for Virat Special Steels – who stock and supply just about every grade of special steel that exists. The following grades of steel are available with them on off-the-shelf basis:

- DIE STEELS (DIN-1.2714)

- HOT WORK STEELS (H-11, H-13, DB6, DIN 1.2714)

- COLD WORK STEELS (HCHCr, D-2, D-3, DIN 2379, DIN 2080)

- HIGH SPEED STEELS (M-2, M-35, T-1)

- PLASTIC MOULD STEELS (P-20, DIN 2738)

- ALLOY STEELS (EN-SERIES)

And so, suppliers of die steel, Virat Special Steels Private Limited have built an impressive facility to ensure that in addition to the best quality, allied needs in procurement of special steel can be met. This includes twelve Fully Automatic Band-Saw Machines (from AMADA – JAPAN) with complete cutting capacity extending to 1500 sq.mm to provide customers with suitable sizes. It extends to a fully equipped quality assurance and process examination amenity with Hardness Testers for both Rockwell and Brinell scales; Ultrasonic Machines; Chemical Lab for Testing, Spectro Meters, Micro Meters and suchlike.

This results in huge value additions for customers because not only is the most appropriate type of steel readily available for their specific application; but also because these, as well as treatment procedures such as nitriding and heat treatment, can be examined and thus optimized.

Customers in Ludhiana, Punjab and nearby regions trying to locate Suppliers of Tool Steel and Stockists of Mould Steel, should note that the Virat package – a combination of the best price, immediate availability and testing capability is unparalleled.

Tool and Die Steel Supplier in Kundli, Sonepat, Narela Haryana!

Kundli in Sonepat, Haryana, indeed stands out as a hub of industrial excellence, particularly in the steel sector. Its reputation as a top exporter in the domestic market is well-earned, thanks to the high-quality tool and die steel products it manufactures. The city’s expertise in creating specialized items like stamping dies, cutting dies, box dies, clutch facings, terminal blocks, and embossing dies is a testament to its skilled workforce and advanced manufacturing capabilities.

These products are essential components in various manufacturing processes, contributing significantly to industries such as automotive, electronics, and construction. The precision and durability of the tools and dies produced in Kundli reflect the region’s commitment to quality and innovation, making it a vital player in India’s industrial landscape.

In Kundali, Sonepat, Haryana, there are several manufacturers and suppliers in the tools and die steel industry. The requirements for tools and die steel depend on the application, the material to be processed, the design of the tool or die, and the operating conditions. It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.

Tool and die steels are specialized materials used in various industries due to their durability and resistance to wear.

Here are some common applications:

- Cutting Tools: Used for making drills, taps, reamers, and other cutting implements.

- Forming Tools: Includes bending, trimming, and drawing dies, as well as embossing and extrusion dies.

- Shearing Tools: For making blades for shears, punches, and dies used in shearing operations.

- Stamping Tools: Employed in stamping and pressing processes to shape metals and plastics.

- Moulds: Utilized in plastic injection moulding machines to create a wide array of plastic components.

- Gauges and Measuring Tools: Precision tools that require high wear resistance.

- Machine Dies: For shaping materials through machining processes.

One of the best Tool & Die Steels Supplier in Kundli & Sonepat city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Consult our Gurugram office for further assistance.

Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com.

Contact them by mobile numbers +91- 98140 – 21775, 99991 – 24971 to 79.

How do you choose the right die steel for your forging process?

Choosing the right die steel for your forging process involves several key factors to ensure optimal results and longevity of the dies.

Here are the considerations you should make:

- Strength and Toughness: Select a steel that offers high strength to withstand the stresses of forging without deforming, and toughness to resist cracking under impact.

- Heat Resistance: The steel should maintain its properties at the high temperatures used in forging, preventing premature wear or failure.

- Durability: Consider the wear resistance of the steel, as dies are subject to constant abrasion during the forging process.

- Composition: The alloying elements in the steel, such as chromium, molybdenum, and vanadium, can enhance specific properties like heat resistance and durability.

- Forging Process: The type of forging process (open-die, closed-die, etc.) can influence the choice of steel, as different processes may require different steel properties.

- Work Material: The type, thickness, and hardness of the material being forged will affect the choice of tool steel.

- Production Volume: The number of parts to be produced can also dictate the choice of steel, as high-volume runs may require a steel with greater wear resistance.

- Cost: Balance the cost of the steel with the performance requirements. More expensive steels may offer better performance but could be overkill for less demanding applications.

By carefully considering these factors, you can select a die steel that meets the specific needs of your forging process and contributes to the overall success of your operation. Remember to consult with steel suppliers or specialists if you need more detailed advice tailored to your particular situation.

Are you looking for Drop Forging Press #DieSteelH13?

H13 tool steel is a widely used die steel for drop forging presses, known for its excellent properties such as high toughness, thermal fatigue resistance, and high hardenability. It’s particularly well-suited for applications that require resistance to thermal shock and cracking, making it ideal for the harsh conditions of drop forging.

If you’re in need of H13 tool steel for your drop forging press, Virat Special Steels offers a comprehensive range of H13 steel in various shapes and sizes to meet your requirements. With options in flat, square, and round bar forms, they can cater to any specific needs you might have.

For personalized assistance and to address any queries regarding H13 steel, don’t hesitate to reach out to the Virat Special Steels team. They are equipped to provide you with expert guidance and support.

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

Are you looking for Tool and Die Steel Supplier in Manesar!

Manesar is a planned city and a municipal corporation in the Gurugram district of Haryana, India. It is part of the National Capital Region of Delhi and an industrial hub with many multinational corporations. It was founded in 1976 and has grown rapidly in the past few decades. It has a population of about 23,000 and covers an area of 124 square kilometers.

Manesar is a planned city and an industrial hub in Haryana, India. It has many multinational corporations and startups in various sectors, such as automobile, IT, BPO, banking, finance, manufacturing, and more. Manesar is a city in Haryana, India, that has many steel industries. Some of the companies that manufacture or supply steel products in Manesar. Tool and die steel are types of steel that are used for making various industrial tools and dies. Tools and dies are devices that are used to cut, shape, form, or mold materials such as metal, plastic, rubber, etc. Some examples of tools and dies are punches, dies, molds, jigs, fixtures, etc.

One of the best Tool & Die Steels Supplier in Manesar city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc. Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website:

https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-manesar/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Tool and Die Steel Supplier in Faridabad, Haryana!

Are you looking for Tool and Die Steel Supplier in #Faridabad, #Haryana?

Tool and Die Steel Supplier in Faridabad

Faridabad is the most populous city in the Indian state of Haryana and a part of Delhi National Capital Region. It is one of the major satellite cities around Delhi and is located 284 kilometres south of the state capital Chandigarh. The river Yamuna forms the eastern district boundary with Uttar Pradesh. Faridabad was founded in 1607 by Shaikh Farīd, treasurer for the Mughal emperor Jahāngīr, to protect the high road between Delhi and Agra. It is a major industrial hub and a smart city under the Government of India’s flagship Smart Cities Mission.

Faridabad is a city in Haryana, India, that has many steel industries. Some of the companies that manufacture or supply steel products in Faridabad.It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.Tools and die steel industries are companies that manufacture or supply tools and dies for various industrial applications. Tools and dies are specialized devices that are used to cut, shape, form, or mold materials such as metal, plastic, rubber, etc. Some examples of tools and dies are punches, dies, molds, jigs, fixtures, etc.

One of the best Tool & Die Steels Supplier in Faridabad city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India. You can visit their website: https://www.viratsteels.com/

The following grades of steel are available with them on an ex-stock basis:

- 1. DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- 2. HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- 3. PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- 4. HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- 5. COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- 6. ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Consult our Gurugram office for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Best quality tool steel, die steel, and mold steel suppliers for engineering work in India!

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry – Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions – In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: – Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry – Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: – Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry – Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: – DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways – They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas – Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

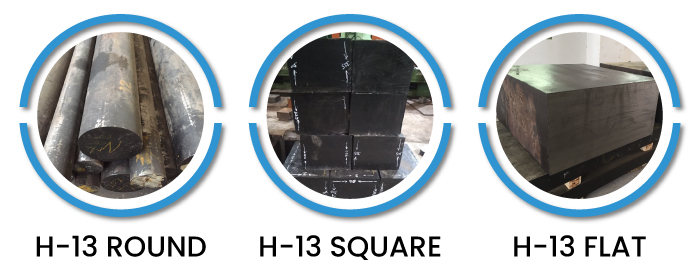

India’s top Largest Supplier, Stockiest, Importer and Exporter of H13 Tool Steel!

VIRAT SPECIAL STEELS Pvt. Ltd. Introduce H-13 material & Modify H13 (DIN 2344 / SKD61/ AISI H13) for the application of drop forgings, Extrusion, Pressure Die Casting etc. H13 steels belong to a family of Hot-Working Steels, a group of steel that is used to cut or shape material at high temperatures. These H-group tool steels were developed for strength and hardness during prolonged exposure to elevated temperatures. These tool steels are low carbon and moderate alloy with significant carbide content resulting in good hot hardness and toughness, coupled with fair wear resistance. The main alloy constituents of H13 are Chromium (4.75 to 5.5%); Molybdenum (1.1 to 1.75%); Vanadium (0.8 to 1.2%); and nominal volume of Nickel (only 0.3%).

While Molybdenum and Vanadium provide strength, the high Chromium content makes H13 resistant to softening when at high temperatures (red hardness). H-13 is also resilient in to shock and abrasion. It is capable of withstanding rapid cooling and not prone to heat checking (cracking because of large changes in temperature).

Ease of fabrication is an important consideration in selection of tool steel and H13 steels score highly on this issue. The primary factors that influence easy fabrication are: good Machinability (H series steels score 70 on the Index where W-class steels are at 100), Grindability, Weldability, Hardenability, and Resistance to Distortion, Safety (cracking resistance) and Decarburizing Tendency. H13 steels are high on all these and can be formed (shaped into tool or mould) by conventional means.

Weldability matters mainly for large tools and is the ability to make, alter and repair a tool by welding without the material cracking. A simplistic explanation of Hardenability is whether hardness is maintained through the depth of the material.

H13 steels are particularly useful where precision is required such as for small and medium sized extrusion dies; and ejector pins, apparatus holders and shrink fit chucks. Also for making inserts, cores, and cavities for die casting dies, die casting shot sleeves, hot forging dies, and plastic mould cavities and parts that require a smooth finish.

A major advantage with H13 steels is that they can be Precision-Cast. Not only are cast tools superior to wrought tools in terms of resistance to thermal checking; but if they can be precision cast to near finished size they save significantly on waste and machining. They also allow for pattern making costs to be spread over a large population of tools.

H13 tool steels are practically equivalent to DIN 1.2344 (Europe) and quite similar to grades AFNOR Z 40 COV 5, UNI KU, JIS SKD61, SS 2242, B.S. BH 13 & ASTM A681.

Virat Special Steels – India’s top Largest Supplier, Stockiest, Dealer, Trader Importer and Exporter of H13 Tool Steel and DB6 Tool Steel.

Learn More:

https://www.viratsteels.com/h13.html

What is the differences between the H11 and H13 Hot Work Steel?

If we compare between H11 and H13, H11 tool steel consists of less vanadium than the commonly used H13 hot work tool steel. This gives H11 steels the higher toughness, with some reduction in wear resistance and tamper resistance. H13 and H11 are both types of tool steels commonly used in the manufacturing and tooling industry, but they have different characteristics and applications.

Let’s compare H13 steel and H11 steel:

- Chemical Composition:

- H13 Steel: H13 is a hot work tool steel and is characterized by its high chromium content (around 5%) and molybdenum (1.4-1.75%). This composition gives it excellent heat resistance and wear resistance.

- H11 Steel: H11, on the other hand, is a hot work tool steel with a lower chromium content (around 4%) and no molybdenum. It has good toughness and heat resistance but is not as heat-resistant as H13.

- Heat Resistance:

- H13 Steel: H13 steel has excellent heat resistance, making it suitable for high-temperature applications such as die casting, forging, and extrusion.

- H11 Steel: H11 steel also offers good heat resistance, but it may not perform as well as H13 in extremely high-temperature environments.

- Toughness:

- H13 Steel: While H13 steel is tough, its primary strength lies in its heat resistance and wear resistance rather than toughness.

- H11 Steel: H11 steel is known for its toughness and is often used in applications where impact resistance is crucial, such as hammer forging and die casting.

- Applications:

- H13 Steel: H13 steel is commonly used in applications where high-temperature resistance and wear resistance are critical, including die casting dies, extrusion tools, and hot forging dies.

- H11 Steel: H11 steel is preferred for applications requiring good toughness and resistance to thermal fatigue, such as hammer and press forging, and certain types of die casting.

- Machinability:

- H13 Steel: H13 steel can be more challenging to machine due to its high hardness and heat resistance. Proper tooling and machining techniques are required.

- H11 Steel: H11 steel is generally easier to machine compared to H13, thanks to its lower hardness.

- Cost:

- H13 Steel: H13 steel is typically more expensive than H11 due to its superior heat resistance and wear resistance properties.

In summary, the choice between H13 and H11 steel depends on the specific requirements of your application. If you need high heat resistance and wear resistance, H13 may be the better choice. However, if toughness and resistance to thermal fatigue are more important, H11 could be the suitable option. Additionally, cost considerations can also influence the choice between these two tool steels.

APPLICATIONS:

Forging Dies, Punches / Dies for Extrusion on non ferrous alloys, Pressure Die Casting of Aluminium Alloys, Moulds for Thermo plastic polymer injection with high polishability. Die Inserts, Extrusion Press Tools, Forming Dies, Mandrels, Hot Shear Blades, Rolls for Hot Rolling Machines,Tools for Nuts,Screws, Bolts, Rivets, Fasteners, etc

Mode of Supply:

The Prime Supplier of Hot Work Steel in India is “VIRAT SPECIAL STEELS,” an ISO 9001:2008 certified company. Recognized globally as suppliers of quality steel they enjoy enviable affiliations with the leading producers of special steels and heavy engineering across the world. So their advice and solutions should prove invaluable in the choice of steel for different applications – such as guidance on whether H13 or H11 is better suited for your process.

Learn more:

https://www.viratsteels.com/hot-work-steel.html

https://www.viratsteels.com/h13.html

https://www.viratsteels.com/h11.html

Email us: info@viratsteels.com

Call Us Now: +91-9814021775