AISI H11

now browsing by category

Are you looking for trusted Tool and Die Steel Supplier in Indore?

Indore, the bustling city in the heart of Madhya Pradesh, India, is a blend of rich cultural heritage and industrial prowess. Founded in 1715, Indore’s history is deeply intertwined with the Maratha Holkars, serving as the capital of their princely state and later as the summer capital of Madhya Bharat state. Today, Indore stands as a testament to its past while forging a path as a major industrial and educational center.

Tool and Die Steel Supplier in Indore

The city’s industrial landscape is diverse, with a significant presence in the tool and die steel sector. These industries are crucial for supporting various other sectors, including automotive, aerospace, and medical industries, by manufacturing and supplying essential tools, dies, molds, and components. The growth of these industries reflects Indore’s commitment to development and innovation.

One notable company contributing to this industrial segment is Virat Special Steels Pvt. Limited. With a focus on a wide range of specialized steels, they cater to the demanding needs of modern industries. Their services extend beyond supply, offering material machining, custom cut pieces, and metallurgical advice, ensuring that clients receive not just products but complete solutions.

Virat Special Steels exemplifies the industrial spirit of Indore, showcasing the city’s ability to adapt and thrive in the ever-evolving economic landscape. Their state-of-the-art facilities in Gurugram and Ludhiana, coupled with a robust distribution network, underline their commitment to quality and customer satisfaction.

If you’re looking for a Tool & Die Steel supplier in Indore, I recommend checking out Virat Special Steels Pvt. Limited. They are one of the best suppliers in the city, offering a wide range of steel products for various industrial applications.

Here are some details about Virat Special Steels:

Company Overview: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made material.

Product Range:

- Die Steel (HH 370 – 410 BHN): This includes grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

Quality Assurance and Facilities:

Virat Special Steels boasts an impressive fully equipped quality assurance and process examination facility. This includes:

- A laboratory for analyzing steel through chemical tests and spectrometry.

- Ultrasonic examination and hardness testing on Vickers, Rockwell, and Brinell scales.

These facilities allow clients to select the most appropriate type of steel for their specific applications and optimize costs in the long run.

Make In INDIA:

Virat Special Steels offers “Make In INDIA” products at competitive prices, great quality, and prompt servicing. They aim to increase and improve CPC (Cost Per Component) for their customers.

Any further queries feel free to contact us :

☎ +91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

What is the differences between the H11 and H13 Hot Work Steel?

If we compare between H11 and H13, H11 tool steel consists of less vanadium than the commonly used H13 hot work tool steel. This gives H11 steels the higher toughness, with some reduction in wear resistance and tamper resistance. H13 and H11 are both types of tool steels commonly used in the manufacturing and tooling industry, but they have different characteristics and applications.

Let’s compare H13 steel and H11 steel:

- Chemical Composition:

- H13 Steel: H13 is a hot work tool steel and is characterized by its high chromium content (around 5%) and molybdenum (1.4-1.75%). This composition gives it excellent heat resistance and wear resistance.

- H11 Steel: H11, on the other hand, is a hot work tool steel with a lower chromium content (around 4%) and no molybdenum. It has good toughness and heat resistance but is not as heat-resistant as H13.

- Heat Resistance:

- H13 Steel: H13 steel has excellent heat resistance, making it suitable for high-temperature applications such as die casting, forging, and extrusion.

- H11 Steel: H11 steel also offers good heat resistance, but it may not perform as well as H13 in extremely high-temperature environments.

- Toughness:

- H13 Steel: While H13 steel is tough, its primary strength lies in its heat resistance and wear resistance rather than toughness.

- H11 Steel: H11 steel is known for its toughness and is often used in applications where impact resistance is crucial, such as hammer forging and die casting.

- Applications:

- H13 Steel: H13 steel is commonly used in applications where high-temperature resistance and wear resistance are critical, including die casting dies, extrusion tools, and hot forging dies.

- H11 Steel: H11 steel is preferred for applications requiring good toughness and resistance to thermal fatigue, such as hammer and press forging, and certain types of die casting.

- Machinability:

- H13 Steel: H13 steel can be more challenging to machine due to its high hardness and heat resistance. Proper tooling and machining techniques are required.

- H11 Steel: H11 steel is generally easier to machine compared to H13, thanks to its lower hardness.

- Cost:

- H13 Steel: H13 steel is typically more expensive than H11 due to its superior heat resistance and wear resistance properties.

In summary, the choice between H13 and H11 steel depends on the specific requirements of your application. If you need high heat resistance and wear resistance, H13 may be the better choice. However, if toughness and resistance to thermal fatigue are more important, H11 could be the suitable option. Additionally, cost considerations can also influence the choice between these two tool steels.

APPLICATIONS:

Forging Dies, Punches / Dies for Extrusion on non ferrous alloys, Pressure Die Casting of Aluminium Alloys, Moulds for Thermo plastic polymer injection with high polishability. Die Inserts, Extrusion Press Tools, Forming Dies, Mandrels, Hot Shear Blades, Rolls for Hot Rolling Machines,Tools for Nuts,Screws, Bolts, Rivets, Fasteners, etc

Mode of Supply:

The Prime Supplier of Hot Work Steel in India is “VIRAT SPECIAL STEELS,” an ISO 9001:2008 certified company. Recognized globally as suppliers of quality steel they enjoy enviable affiliations with the leading producers of special steels and heavy engineering across the world. So their advice and solutions should prove invaluable in the choice of steel for different applications – such as guidance on whether H13 or H11 is better suited for your process.

Learn more:

https://www.viratsteels.com/hot-work-steel.html

https://www.viratsteels.com/h13.html

https://www.viratsteels.com/h11.html

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

Tool and Die Steel Supplier, Stuckist in Delhi NCR

Owing to environmental considerations, the city of Delhi, India, which is also a Union territory of some 20 million people, has seen much manufacturing activity moving out. It still continues with immense construction activity and as a thriving trading hub. Also Delhi is well connected to major industrial centers in the region; has an abundance of established suppliers for every commodity that includes steel and so, it is a convenient place to do business. Special steels continue to be in demand in its steel markets.

Both the engineering sector and steel traders in Delhi should consider getting in touch with Virat Special Steels, Gurgaon (Haryana) India – who is one of India’s top Tool & Die Steel suppliers. Also Stockists of Mould Steel, they can, with a little notice supply just about every grade of special steel that exists.

The following grades of steel are available with them on an ex-stock basis:

- DIE BLOCKS (DIN-1.2714)

- PLASTIC MOULD STEELS (P-20 / 2738)

- CHIPPER KNIVES STEELS

- HOT DIE STEELS (H-11,H-13 / 2343, 2344)

- HIGH SPEED STEELS (M-2, M-35, T-1)

- HIGH CARBON HIGH CHROMIUM STEELS (D-2, D-3 / 2080, 2379)

- ALLOY STEELS, EN-SERIES

They can also arrange for the following:

AFNOR Z 200 C 12; DIN 1.2080; UNI X 21O Cr 13 KU; JIS SKD1; B.S. BD 3;

ASTM A681; FED QQT570; SAE J437; SAE J438 and any other niche steel.

Virat Special Steels Private Limited, also have their steel yards and works in Gurgaon (Haryana) India. They maintain an inventory of special steels exceeding 3500 tonnes; and in their works, they operate 21 bimetal horizontal and vertical band saw cutting machines with capacity upto 2500 mm x 1100mm, their own machining shop, 20 magnetic lifts with capability of handling loads of upto 5 tonnes, 14 overhead lifting cranes that can handle loads of upto 20 tonnes, and fork lift trucks and all other required paraphernalia for immediately servicing customer orders in suitable sizes.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

At par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Both users and traders in Delhi will find more information on them at sites: www.viratsteels.com and info@viratsteels.com. or on mobile number +91-98140 21775.

How do you choosing the right steel grade for forging ?

During forging, metal is pressed, pounded, or squeezed under great pressure into high strength elements called forgings.

Preheating the metal to the desired temperature before working it is often (but not always) a part of the method. Forging is a totally different process from casting (or foundry) since the metal used to make forged parts is never melted and poured (as in casting).

The forging process will produce parts that are stronger than those manufactured by the other shaping method. This is often why forgings are nearly always used wherever dependability and human safety are essential. However you will rarely see forgings as they are normally component parts contained within assembled things such as airplanes, cars, tractors, ships, oil drilling instrumentation, engines, missiles and all forms of capital equipment.

Steel is an iron-based alloy with small additions of carbon and other elements that impart improvements in various properties. Steel is among the most useful of metals. It is the metal that has the highest strength per unit cost. There are a wide range of steel compositions as well as a wide range of micro structures that can be produced. These ranges allow a large choice of properties to be achieved within the steel-alloy family.

Properties of Compound Steel:

It contains around 1% to 5% of steel that is consolidated with different components. Diverse combination components have remarkable properties and including these components enhance different qualities.

The normal properties of combination steel are Corrosion Resistance, Machinability, Hardenability and Weldability.

Best Steel for Forging:

In forging maximum used two steel grades i.e. H13 Tool Steel and DB6 Tool Steel. If you are research company that provide you steel for your forging company the you are at right place.

Virat Special Steels – India’s top Largest Supplier, Stockiest, Dealer, Trader Importer and Exporter of H13 Tool Steel and DB6 Tool Steel.

Learn More:

https://www.viratsteels.com/h13.html

https://www.viratsteels.com/db6.html

https://www.db6steel.com/

Any further queries feel free to contact us :

Email us: info@viratsteels.com or Call us now: +91-98140 21775

We Provide our Special Steels in All Cities in #India:

Delhi, #Kolkata, #Chennai, #Bangalore, #Hyderabad, #Ahmedabad, #Pune, #Surat, #Jaipur, #Kanpur, #Lucknow, #Nagpur, #Ghaziabad, #Indore, #Coimbatore, #Kochi, #Patna, #Kozhikode, #Bhopal, #Thrissur, #Vadodara, #Agra, #Visakhapatnam, #Malappuram, #Thiruvananthapuram, #Kannur, #Ludhiana, #Nashik, #Vijayawada, #Madurai, #Varanasi, #Meerut, #Faridabad, #Rajkot, #Jamshedpur, #Bhiwadi , #Rohtak , #Manesar , #Ahemednagar , #Alwar , #Anand , #Belgaum , #Dehradun , #Haridwar , #Mysore, #Noida , #Pithampur , #Rudrapur, #Waluj and many more..

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stockist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes – Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter – Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

Feel free to contact us :

Corporate Office, #Gurgaon

Administrative Office, #Ludhiana

Email: info@viratsteels.com.

or Call us: 098140 21775

Are you looking for DIN 1.2343 Steel?

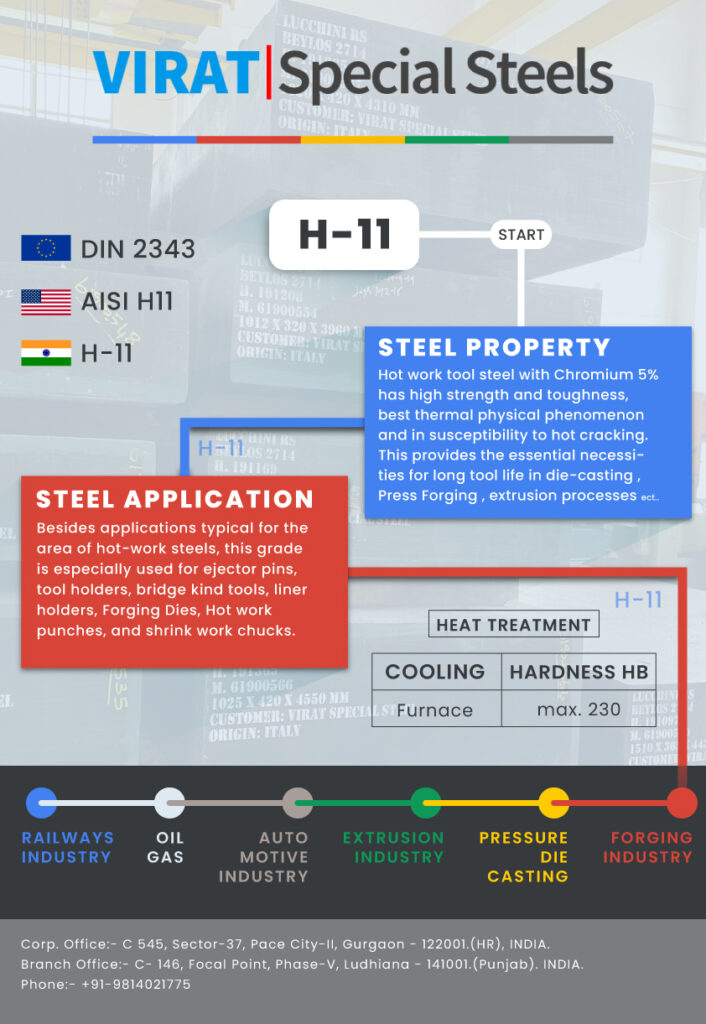

DIN 2343 | H11 | AISI H11 For hot-work steels.

This grade is especially used for ejector pins tool holders, bridge kind tools, liner holders, Forging Dies, Hot work punches, and shrink work chucks industries…

ViratSpecialSteels is the biggest & leading Supplier & Stockiest of Din 1.2343 Hot Work Steel.

Din 2343 is an all inclusive hot work tool steel with hot rigidity and durability. Good thermal conductivity and invulnerability to hot cracking can be water-cooled to a constrained degree.

Utilized for ejector pins, apparatus holders and shrink fit chucks.

Steel Properties:

Hot work tool steel with Chromium 5% has high strength and toughness, best thermal physical phenomenon and in susceptibility to hot cracking. This provides the essential necessities for long tool life in die-casting , Press Forging , extrusion processes etc.

Application:

Besides applications typical for the area of hot-work steels, this grade is especially used for ejector pins, tool holders, bridge kind tools, liner holders, Forging Dies, Hot work punches, and shrink work chucks.

Learn More:

https://www.viratsteels.com/din-2343.html

Read more:

https://www.viratsteels.com/pdf/hot-work-steels/2343.pdf

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91-9814021775