Steel Supplier in Delhi NCR

now browsing by category

Exploring the Role of Special Steels in NOIDA’s Industrial Growth!

NOIDA and Greater NOIDA, adjoining the Indian capital of Delhi, are bustling industrial hubs that have witnessed significant growth over the past few decades. These twin cities in Uttar Pradesh are home to a diverse range of manufacturers, from large automobile producers to small-scale engineering units. The backbone of this industrial diversity is the specialized materials that fuel innovation and efficiency, particularly special steels.

Special Steels Supplier in NOIDA

Special steels are a cornerstone for a vast array of manufacturing processes. They are integral to the production of heavy vehicles, tractors, and automobile transmission parts. Moreover, they play a critical role in general engineering and the manufacture of precision components such as ball and roller bearings, various types of gears, camshafts, universal joints, driving pinions, link components, axles, arbours, gear shafts, and spinning tools.

The proximity of Gurgaon to NOIDA and Greater NOIDA is of strategic importance. Gurgaon, known for its rapid urbanization and commercial development, is also the headquarters of Virat Special Steels. This company stands out as one of India’s premier suppliers of Tool Steel, Die Steel, and Mould Steel. Their extensive inventory includes nearly every grade of special steel available, catering to the nuanced needs of the region’s manufacturers.

The special steels supplied by Virat Special Steels are engineered to meet specific industrial requirements. For instance, case-hardened steel, known for its low carbon content, offers excellent wear resistance due to its high surface hardness. This feature, coupled with a small grain size, ensures that the steel has high ductility and fatigue strength. Nitrided steels are another category that boasts a combination of wear resistance and surface fatigue resistance while maintaining impact strength in the core.

The versatility of special steels is evident in their wide range of applications. High Nickel or Molybdenum steels are sought after for wire drawing due to their strength and durability. High Chrome steels are favored for their resistance to corrosion, making them ideal for harsh working environments.

Virat Special Steels‘ commitment to providing a comprehensive selection of special steels is a testament to their understanding of the industry’s evolving needs. Whether it’s for wire drawing, resisting corrosion, or other specialized applications, they have a steel for every purpose.

Special Steels Supplier in NOIDA, The industrial landscape of NOIDA and Greater NOIDA continues to thrive, thanks in part to the availability and quality of special steels. As industries push the boundaries of innovation, the demand for specialized materials that offer superior performance and durability will only increase. Companies like Virat Special Steels are not just suppliers; they are enablers of industrial progress and contributors to the economic vitality of the region.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Let Virat Special Steels be your trusted partner in driving industrial growth in the Noida and Greater Noida region.

For more information visit:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-noida/

Contact us today to discuss your special steel needs and how we can help propel your projects forward!

📞+91-98140 21775 🌐www.viratsteels.com 📩 info@viratsteels.com

Trusted Tool and Die Steel Supplier in Rohtak, Haryana!

Rohtak, a city within the National Capital Region of Delhi, stands as a testament to India’s rapid industrial growth. Established in 1976, this planned city has burgeoned into an industrial powerhouse, hosting a myriad of multinational corporations and startups across diverse sectors. With a modest population of approximately 23,000, Rohtak covers an area of 124 square kilometers and is strategically positioned in the Gurugram district of Haryana.

The city’s industrial landscape is particularly notable for its concentration of tool and die steel industries. Tool and die steel are specialized materials crafted to withstand the rigors of manufacturing tools, dies, molds, and other components essential for shaping and molding materials like metal, plastic, and rubber. These high-precision instruments are the backbone of manufacturing, enabling the production of intricate parts with consistency and quality.

Among the prominent players in Rohtak’s steel industry is Virat Special Steels Pvt. Limited. This company has carved a niche for itself by dealing in a comprehensive range of steels, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their commitment to quality is evident in their value-added services, which encompass material machining, provision of cut pieces, and the supply of tailor-made material solutions. Furthermore, Virat Special Steels Pvt. Limited extends metallurgical advice and ensures stringent quality assurance, underpinning their reputation as a reliable supplier.

The company’s state-of-the-art facilities in Gurugram and Ludhiana underscore their technological prowess, while a robust distribution network across India signifies their logistical competence. Such attributes not only enhance their standing in Rohtak’s industrial domain but also contribute significantly to the region’s economic vitality.

Here are some details about Virat Special Steels:

Company Overview: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made material.

Product Range:

- Die Steel (HH 370 – 410 BHN): This includes grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

Quality Assurance and Facilities:

Virat Special Steels boasts an impressive fully equipped quality assurance and process examination facility.

This includes:

- A laboratory for analyzing steel through chemical tests and spectrometry.

- Ultrasonic examination and hardness testing on Vickers, Rockwell, and Brinell scales.

These facilities allow clients to select the most appropriate type of steel for their specific applications and optimize costs in the long run.

Make In INDIA:

Virat Special Steels offers “Make In INDIA” products at competitive prices, great quality, and prompt servicing. They aim to increase and improve CPC (Cost Per Component) for their customers.

Rohtak’s evolution from a nascent city to an industrial hub is a narrative of vision, planning, and execution. The city’s tool and die steel sector is a microcosm of this transformation, reflecting the synergy between industrial expertise and infrastructural development. As Rohtak continues to expand and diversify, its role in India’s industrial narrative remains pivotal, promising a future where innovation and growth go hand in hand.

For more information, you can explore here:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-rohtak/

Any further queries feel free to contact us :

☎ +91 98140-21775 🌐https://www.viratsteels.com/

📬 info@viratsteels.com

The Evolution of Steel, a look at the Last 20 Years!

Steel, an alloy of iron and carbon, has been a fundamental building block of modern civilization. Its versatility and strength have made it a material of choice for a myriad of applications, from construction to automotive manufacturing. However, the steel industry is not static; it has undergone significant changes over the past two decades, with over 75% of the 3500 steel grades in use today not existing 20 years ago.

Evolution of Steel, a look at the Last 20 Years.

This rapid evolution in steel grades can be attributed to technological advancements and the industry’s response to the increasing demands for higher performance materials. The development of high-strength, high-performance steel structures is a testament to this progress. These new steel grades are designed to meet specific mechanical properties, chemical compositions, and intended uses, catering to more specialized applications than ever before.

The introduction of these advanced steel grades has necessitated revisions in design standards and codes. For instance, the Eurocode , which provides guidelines for the design of steel structures within Europe, is undergoing updates to incorporate the design rules for these new steel grades. This reflects the industry’s commitment to innovation and safety.

The global steel production has also seen a steady increase, reflecting the growth and demand in various sectors. This growth is supported by the continuous development of steel grades, which has been crucial in meeting the challenges of modern engineering and construction.

The history of steel itself is a fascinating journey from its early beginnings to the modern standards we see today. The mid-20th century marked the need for more specialized steel products, leading to the development of the modern steel grades we are familiar with. This evolution has been driven by the addition of different elements in varying amounts, allowing the material to be tailored for specific applications and industries.

For those interested in exploring this topic further, the article “Implementation of high-strength, high-performance steel structures” provides an in-depth look at the current state and future prospects of steel grades in the construction industry. It is a valuable resource for understanding how the steel industry has adapted to the changing needs of the world.

The evolution of steel grades over the past 20 years is a clear indicator of the industry’s ability to innovate and adapt. It is a story of progress, one that continues to unfold as we push the boundaries of what this essential material can achieve.

The study delves into the value of reestablishing compositional information for steel recycling and sheds light on the dynamic nature of steel grades.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA

Your Trusted Partner in Special Steels. Explore a vast inventory of Die Blocks and Tool Steels sourced from renowned manufacturers worldwide…

Our Steel Yards boast a comprehensive inventory, including:

- DIE STEELS (DIN-1.2714)

- HOT WORK STEELS (H-11, H-13, DB6, DIN 1.2714)

- COLD WORK STEELS (HCHCr, D-2, D-3, DIN 2379, DIN 2080)

- HIGH SPEED STEELS (M-2, M-35, T-1)

- PLASTIC MOULD STEELS (P-20, DIN 2738)

- ALLOY STEELS (EN-SERIES)

Learn more :

https://www.viratsteels.com/

Any queries feel free to contact us : info@viratsteels.com or

Call on mobile number +91-9814021775

MACHINERY & EQUIPMENT at Virat Special Steels!

At Virat Special Steels, we’re not just about steel; we’re about strength, precision, and innovation. Our state-of-the-art machinery and equipment stand as a testament to our commitment to excellence:

Cutting-Edge Bandsaws- Virat Special Steels

Cutting-Edge Bandsaws:

With 27 Bimetal Horizontal & Vertical Bandsaw Machines, we can handle materials up to 2500mm x 1100mm.

Mighty Cranes: Our fleet of 14 Overhead Lifting Cranes can lift a staggering 20 Tons, moving heavy loads with ease.

Powerful Magnets: We have 20 Lifting Magnets, each with a lifting capacity of 5 Tons, ensuring safe and efficient handling of materials.

Versatile Forklifters: Our 2 Fork Lifters are always ready to move loads up to 3 Tons, keeping our operations smooth and steady.

Advanced Labs: Our Chemical & Spectro Lab and UT Testing Machine ensure that every product meets the highest quality standards.

Precision Machining: The Machining Plant is where our products take shape, crafted with meticulous attention to detail.

Quality Assurance: With our Hardness Tester, we guarantee that our steel withstands the toughest conditions.

Virat Special Steels is more than a company; it’s a symbol of reliability and technological prowess. Join us in our journey of industrial excellence and discover the difference that quality makes!

Feel free to tailor this post to match the company’s branding and style. For more information, visit our website. Let’s shape the future with strength and precision! 🛠️✨

Contact us today to learn more!

https://www.viratsteels.com/

Any further queries feel free to contact us :

☎+91 98140-21775 🌐www.viratsteels.com

📬 info@viratsteels.com

Are you looking for Aluminium Extrusion Die Steel in India?

Virat Special Steels Pvt. Limited is a prominent choice. They specialize in high-quality H11 and H13 tool steels, known for their durability and performance in high-temperature applications. These materials are essential for manufacturing processes like die casting, forging, and plastic molding.

Why Choose Virat Special Steels?

- Quality Assurance: Ultrasonic inspection ensures 100% positive results as per NDT standards.

- Specialization: Expertise in H11, H13 / DIN-1.2344, DIN-1.2343 / AISI H11, AISI H13.

- Experience: Over five decades of industry presence.

- Inventory: Ready stock available in various shapes and sizes for immediate needs.

Aluminium extrusion dies are essential tools used in the process of shaping aluminium profiles and components through extrusion. These dies are typically made from high-strength tool steel and are designed to withstand high pressures and temperatures during the extrusion process.

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of H11, H13 / DIN-1.2344 , DIN-1.2343 / AISI H11, AISI H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. All die steel is available in flat, square and round shape.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Any further queries feel free to contact us :

☎+91 098140-21775 🌐www.viratsteels.com

📬 info@viratsteels.com

Strength, Precision, Virat Special Steels – Where Every Cut Counts.

Virat Special Steels’ Machinery & Equipment! 🏗️

At Virat Special Steels, we’re not just about steel; we’re about strength, precision, and innovation. Our state-of-the-art machinery and equipment stand as a testament to our commitment to excellence:

- Cutting-Edge Bandsaws: With 27 Bimetal Horizontal & Vertical Bandsaw Machines, we can handle materials up to 2500mm x 1100mm.

- Mighty Cranes: Our fleet of 14 Overhead Lifting Cranes can lift a staggering 20 Tons, moving heavy loads with ease.

- Powerful Magnets: We have 20 Lifting Magnets, each with a lifting capacity of 5 Tons, ensuring safe and efficient handling of materials.

- Versatile Forklifters: Our 2 Fork Lifters are always ready to move loads up to 3 Tons, keeping our operations smooth and steady.

- Advanced Labs: Our Chemical & Spectro Lab and UT Testing Machine ensure that every product meets the highest quality standards.

- Precision Machining: The Machining Plant is where our products take shape, crafted with meticulous attention to detail.

- Quality Assurance: With our Hardness Tester, we guarantee that our steel withstands the toughest conditions.

Virat Special Steels is more than a company; it’s a symbol of reliability and technological prowess. Join us in our journey of industrial excellence and discover the difference that quality makes!

Contact us today to learn more!

https://www.viratsteels.com/

Any further queries feel free to contact us :

☎+91 98140-21775 🌐www.viratsteels.com

📬 info@viratsteels.com

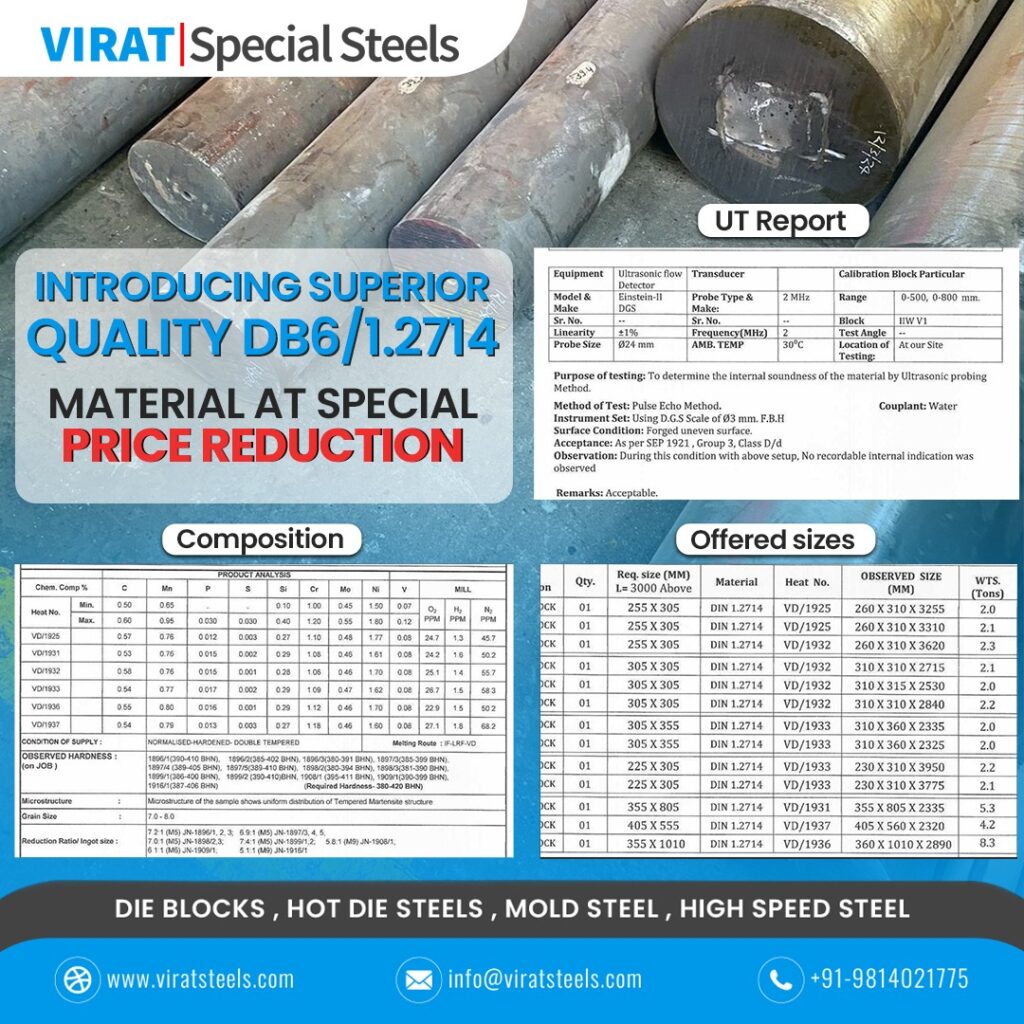

Exciting Offer from VIRAT SPECIAL STEEL!

We’re thrilled to introduce our latest innovation in tool steel – Material 2714 (#DB6), now available at a Special Price Reduction! Experience superior quality with our meticulously crafted steel, designed for high-performance and durability.

Product Specifications:

🔘Round Bars: Diameter ranging from 130mm to 610mm, with a precision machined surface for seamless integration into your projects.

🔘Die Blocks: Thickness from 255mm to 455mm, Width from 255mm to 805mm, and Length from 3 to 5 meters – all forged to perfection for robust applications.

Why Choose Material 2714 (DB6)?

Enhanced Wear Resistance, Ideal for close die forgings, ensuring long-lasting tool life. Exceptional Toughness, provides extra durability against impact and stress. High Hardness, achieved through Cr-Ni-Mo-V high graded alloys for peak performance in demanding conditions.

Don’t miss out on this opportunity to elevate your tooling solutions. Contact us now for more details and secure your order!

For more information visit

https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Tool and Die Steel Supplier in Kundli, Sonepat, Narela Haryana!

Kundli in Sonepat, Haryana, indeed stands out as a hub of industrial excellence, particularly in the steel sector. Its reputation as a top exporter in the domestic market is well-earned, thanks to the high-quality tool and die steel products it manufactures. The city’s expertise in creating specialized items like stamping dies, cutting dies, box dies, clutch facings, terminal blocks, and embossing dies is a testament to its skilled workforce and advanced manufacturing capabilities.

These products are essential components in various manufacturing processes, contributing significantly to industries such as automotive, electronics, and construction. The precision and durability of the tools and dies produced in Kundli reflect the region’s commitment to quality and innovation, making it a vital player in India’s industrial landscape.

In Kundali, Sonepat, Haryana, there are several manufacturers and suppliers in the tools and die steel industry. The requirements for tools and die steel depend on the application, the material to be processed, the design of the tool or die, and the operating conditions. It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.

Tool and die steels are specialized materials used in various industries due to their durability and resistance to wear.

Here are some common applications:

- Cutting Tools: Used for making drills, taps, reamers, and other cutting implements.

- Forming Tools: Includes bending, trimming, and drawing dies, as well as embossing and extrusion dies.

- Shearing Tools: For making blades for shears, punches, and dies used in shearing operations.

- Stamping Tools: Employed in stamping and pressing processes to shape metals and plastics.

- Moulds: Utilized in plastic injection moulding machines to create a wide array of plastic components.

- Gauges and Measuring Tools: Precision tools that require high wear resistance.

- Machine Dies: For shaping materials through machining processes.

One of the best Tool & Die Steels Supplier in Kundli & Sonepat city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Consult our Gurugram office for further assistance.

Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com.

Contact them by mobile numbers +91- 98140 – 21775, 99991 – 24971 to 79.

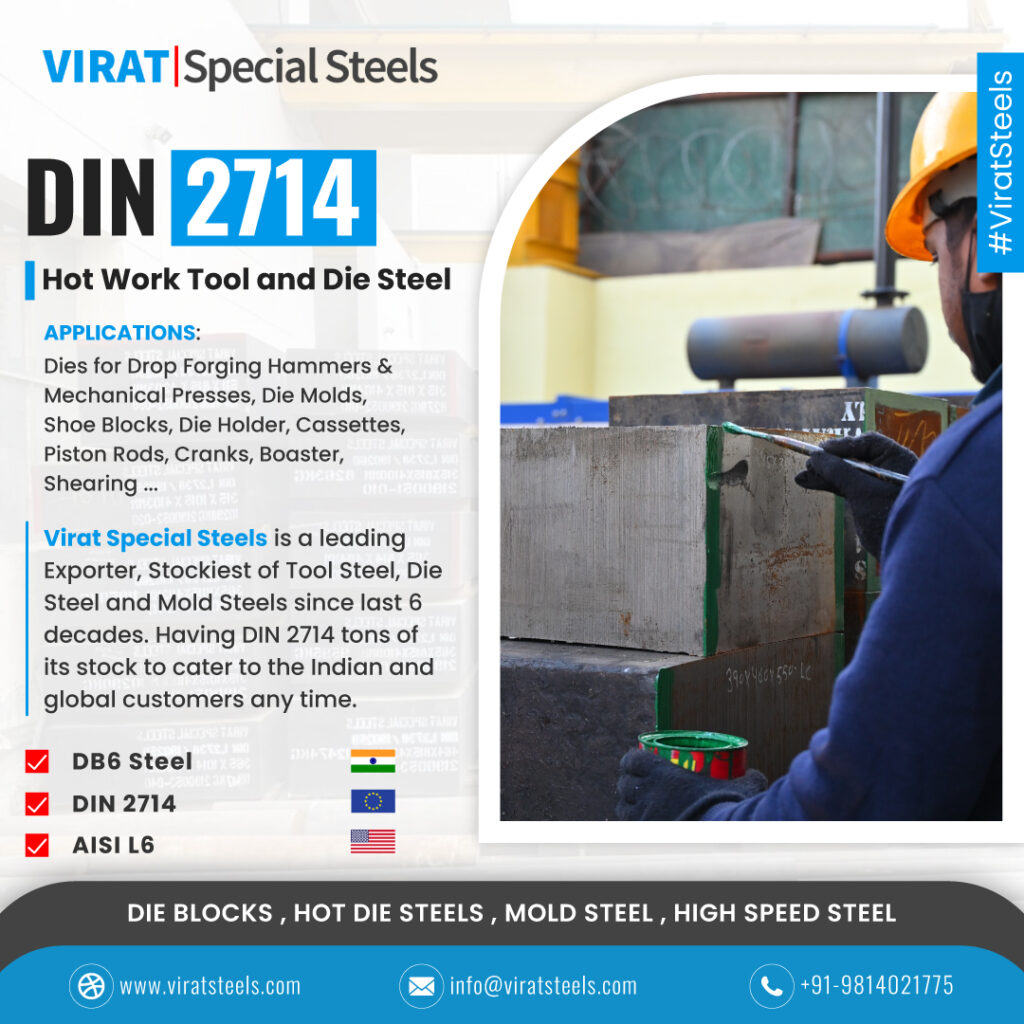

Are you looking for Die Steel blocks 2714 in India?

Die steel blocks 2714 could be a great choice for your close die forging applications!

Discover Quality Die Steel with Virat Special Steels Pvt. Limited.

Virat Special Steels indeed offers a variety of tool steels, including Die steel blocks 2714 (DIN 1.2714). We are known for being one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Die steel blocks 2714, also known as DIN 1.2714, is a hot work tool steel with high toughness and wear resistance, which is achieved through a specific composition of chromium, nickel, molybdenum, and vanadium. This grade of steel is characterized by its high tempering resistance and good through-hardening properties, making it particularly impact-resistant and suitable for large hammer and press dies.

Applications:

It’s commonly supplied in a pre-hardened condition and has a typical working hardness range of 360 to 430 BHN (Brinell hardness number). DIN 1.2714 steel is used for various applications, including forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, tools, and more.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels… Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Contact us today to buy the best quality DIN 2714 steel for your tooling needs!

Learn more: https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

Sourcing Die and Tool Steels for Faridabad

Located in the National Capital Region of neighboring Delhi, Faridabad is the largest city in the state of Haryana. Being the major industrial hub of Haryana, Faridabad is the manufacturing base for giant companies such as Escorts, Yamaha, JCB, Larsen & Toubro, Whirlpool, Goodyear, Bata and Eicher. Its factories pour out a profusion of goods such as tractors, motorcycles, switch gears, refrigerators, shoes, tyres and garments and are all supported by ancillary industries of medium and small scale. More than 5,000 units of auto parts producers alone are located in Faridabad.

Die steel, Tool steel and Mould steel being integral to their manufacturing operations, industries of Faridabad would find great value by connecting with Virat Special Steels Private Limited suppliers of die steel, Suppliers of Tool Steel and Stockists of Mould Steel who are headquartered in Gurgaon less than 50 km away.

They maintain an inventory of 3500 tonnes of special steels for dies, tools and moulds which they cut to upto 2500mm – 1100mm as per customer requirement. They also have a fully equipped quality assurance and process examination facility that conducts tests such as for hardness and analyses grain structure. This helps customers in procuring steel that is best suited for their applications.

As one of India’s leading special steel suppliers, Virat Special Steels can supply the following grades practically off-the-shelf:

For Forging (Cold, Warm or Hot):

Steel grades – Din 1.2714/DB6; DIN 1.2344 / H13; DIN 1.2343 / H11.

For Pressure Die Casting:

Hot die steel – DIN 1.2344 / H13; DIN 1.2343 / H11; DIN 1.2581 / H21.

For Extrusion:

Hot die steel – DIN 1.2344 / H13 (of type known for excellent finish)

For the Automotive Industry:

The Automotive industry with its ancillaries, require a wide range of special steel. Every such requirement can be met and special alloys prepared.

To list some that are immediately available:

Steel grades Din 1.2714 / DB6; DIN 40NiCrMo84 / EN24; DIN 3343 / M2;

Manganese steel such as: 16MnCr5; 20Mncr5.

For Plastic Moulding:

Dies for Polymer material used for aerospace, building, construction, shells for TV – laptops etc, toy making, electronics, packaging and transportation.

Steel grades – DIN 2738(P20+ Ni), DIN 2311(P20).

For Components:

Such as bearing, chains, cranks, handlebars, forks.

Steel grades – Din 1.2714/DB6; DIN 1.2344 / H13; DIN 1.2343 / H11.

In addition to the above Virat Special Steels look forward to supplying any niche steel alloy that customers may require.

Steels supplied by Virat Special Steels are at par with those from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel and others, in terms of Quality, Price & Services.

Thus Virat Special Steels offer “Make In INDIA” products at competitive prices, better quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Customers all over the NCR region including Faridabad will find information on them at sites: www.viratsteel.in and www.viratsteels.com and email us at info@viratsteels.com

They can be contacted on mobile numbers +91- 98140 – 21775, 99991 – 24971 to 79.