Drop forging die 2714

now browsing by tag

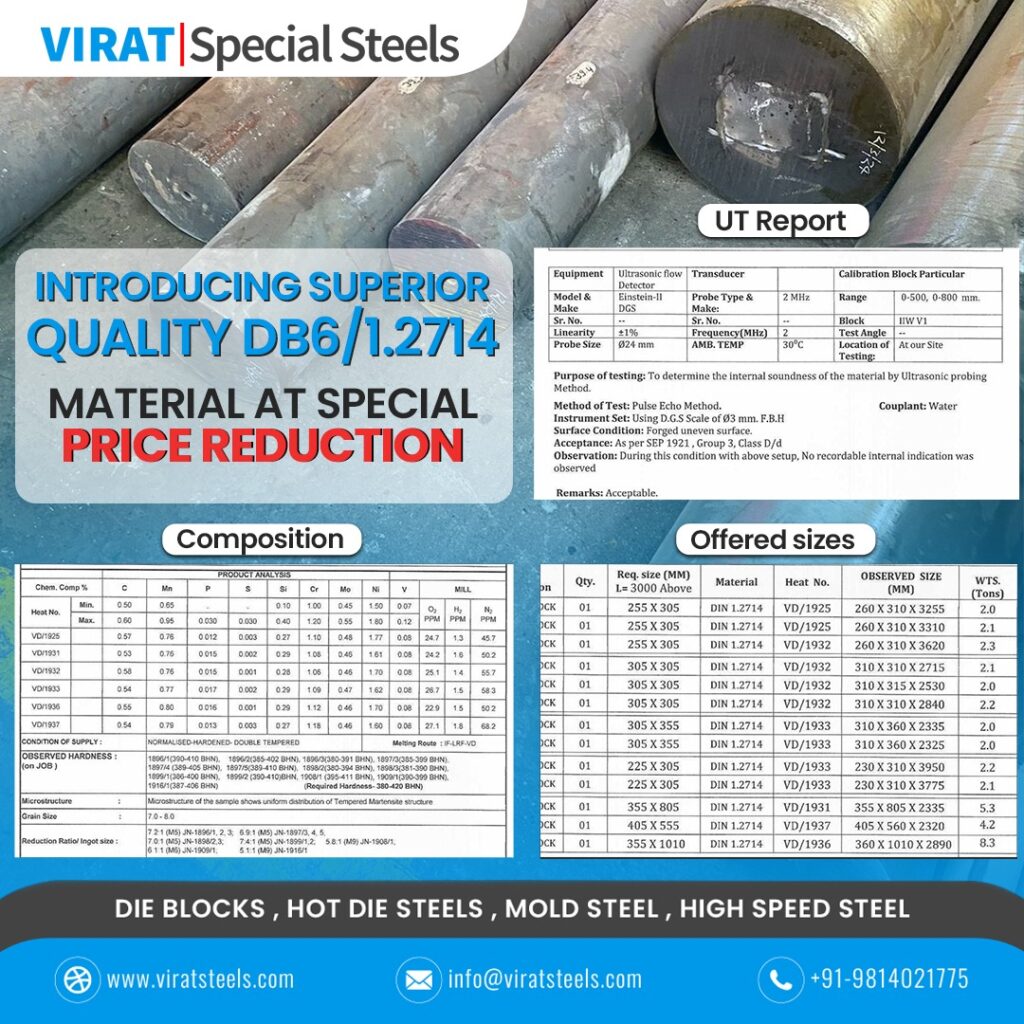

Precision Forging Starts with DIN 2714 – Trust Virat Steels!

The world of manufacturing is ever-evolving, and precision forging is at the forefront of this industrial revolution. A key player in this domain is DIN 2714 tool steel, also known as DB6 or AISI L6. This grade of steel is renowned for its exceptional properties, making it a top recommendation for Close Die Forgings. Let’s delve into the characteristics that make DIN 2714 the go-to material for high-stress applications.

Drop forging die 2714

Grade Brief:

DIN 1.2714 is a testament to engineering excellence, showcasing high wear-resistance, extra toughness, and remarkable hardness. These traits are attributed to its Cr-Ni-Mo-V high-graded alloy composition. Typically utilized in a pre-hardened state, it offers a standard hardness ranging from 360 to 430 BHN, ensuring durability and longevity in its applications.

Applications:

The versatility of DIN 2714 is evident in its wide range of applications. It’s the material of choice for Close Die Forgings, where precision is paramount. The automotive industry benefits from its resilience, while the aerospace sector values its reliability. In metalworking and tool and die manufacturing, DIN 2714’s properties are indispensable for creating high-quality, durable tools and components.

Mechanical Properties:

DIN 2714′s mechanical properties are impressive, with tensile strength ranging from 1000-1400 MPa and a yield strength of 1045 MPa. Its elongation rate of 15%-20% is coupled with impact toughness of 20 J/cm² – 25 J/cm² and a hardness of 50-55 HRC. With a compressive strength of 2500 MPa and a modulus of elasticity of 205 GPa, it stands as a robust option for demanding industrial tasks.

Physical Properties:

The coefficient of thermal expansion (20-600°C) stands at 14.3 x 10⁻⁶ m/(m·K), and its thermal conductivity at 20°C is 36.0 W/(m·K). These physical properties highlight DIN 2714’s ability to withstand varying temperatures, a crucial factor in forging and other high-temperature processes.

Virat Special Steels takes pride in providing DIN 2714 tool steel in various forms, including flat, square, and round bars. Catering to specific industry needs, they offer this steel in pre-hardened, quenched and tempered, or annealed conditions. Their commitment to quality and customer satisfaction is evident in their open invitation for consultations on DIN 2714 steel.

In conclusion, DIN 2714 stands as a pillar of strength and reliability in the world of precision forging. Its comprehensive properties and adaptable applications make it a valuable asset for industries striving for excellence. Trust in Virat Steels to deliver the best in DIN 2714 tool steel, and propel your manufacturing processes to new heights.