DIN 2714 steel

now browsing by category

Virat Steels & NLMK Verona at Mach Auto Expo 2026 | European Tool Steel Excellence

Virat Steels & NLMK Verona at Mach Auto Expo 2026 | European Tool Steel Excellence

The countdown has begun for Mach Auto Expo 2026, India’s premier exhibition for industrial innovation, and this year promises something truly special. Virat Special Steels Pvt. Ltd., a trusted name in premium steel solutions, is proud to partner with NLMK Verona, Europe’s renowned tool steel manufacturer, to display the cutting-edge products and global expertise under one roof.

A Partnership Forged in Strength

Virat Special Steels Pvt. Ltd. has always been committed to delivering world-class steel solutions. By joining hands with NLMK Verona, we bring the best of European tool steel technology directly to Indian manufacturers. This collaboration ensures:

- Superior quality standards backed by European precision.

- Wide product range for automotive, engineering, and heavy machinery sectors.

- Global expertise with local support, combining NLMK’s innovation with Virat’s trusted service.

Why Visit us at Mach Auto Expo 2026?

At our booth, visitors will experience:

- Live product showcases of premium tool steels designed for durability and performance.

- Technical insights from experts on applications, machining, and heat treatment.

- Networking opportunities with industry leaders and decision-makers.

- Exclusive offers for expo attendees, reinforcing our commitment to customer success.

India’s manufacturing sector is evolving rapidly, and the demand for high-performance tool steel is greater than ever.

Join Us at Mach Auto Expo 2026

📍 Hall No. 1 | Booth No. B7 , LEC Ludhiana, Punjab

📅 Date: February 20th ,21st, 22nd,23rd 2026

Whether you are an OEM, supplier, or industry enthusiast, this is your chance to explore European tool steel excellence—right here in India.

Connect With Us Today –

📧 Email: info@viratsteels.com 🌐 Website: www.viratsteels.com 📞 Phone: +91-9814021775 ,9216321774 ,9216321778

Virat Steels & NLMK Verona – Building Strength, Shaping the Future.

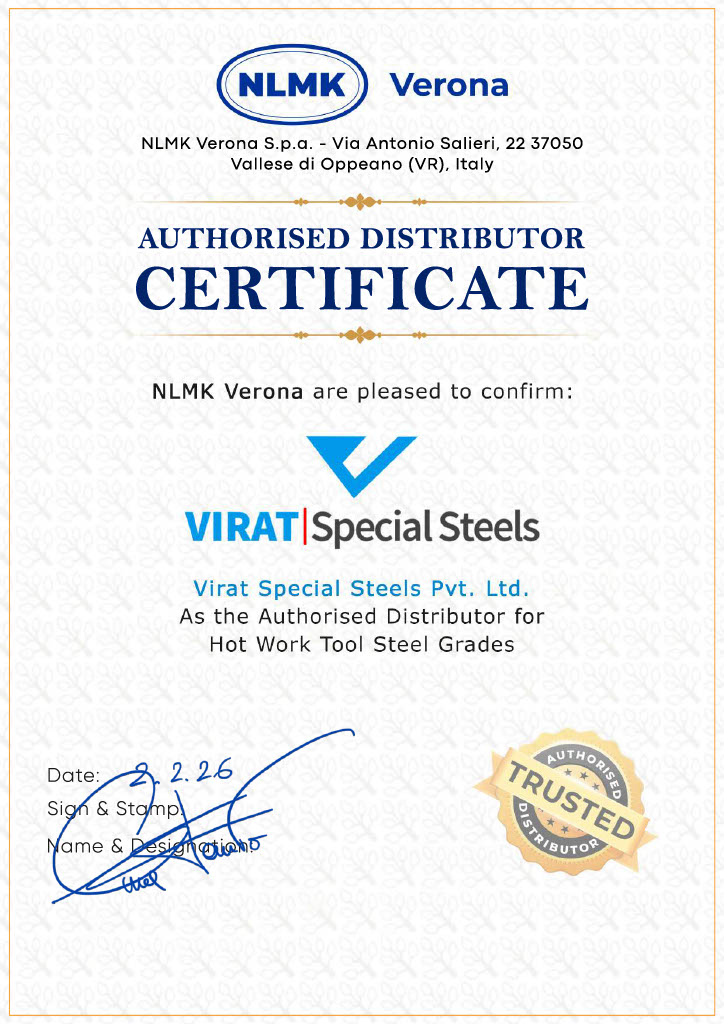

Virat Special Steels Recognized as Authorised Distributor by NLMK Verona

[Strengthening India’s Access to Genuine European Tool Steel]

Virat Special Steels Pvt. Ltd. is proud to announce a significant milestone in our journey—official recognition as the Authorised Distributor for Hot Work Tool Steel Grades by NLMK Verona S.p.a., Italy. This milestone, dated 2nd February 2026, marks a new chapter in our commitment to delivering excellence in the steel industry.

Virat Special Steels Pvt. Ltd. has been recognized as one of the largest Importers, Exporters, and Stockists of premium steel products of :

- Die Blocks (DIN 1.2714, DB6, H13, H11)

- Tool Steels & Die Steels

- Special Steels & Alloy Steels in multiple grades

Backed by decades of expertise, the company maintains the largest steel yards, ensuring consistent availability, unmatched quality, and timely delivery to domestic industries.

NLMK Verona, a renowned name in the global steel sector, has entrusted Virat Special Steels with the responsibility of distributing their Hot Work Tool Steel Grades in India. This partnership reflects not only our technical expertise but also the trust we have built over the years with our customers and partners.

What This Means for Our Customers

Being an Authorised & Trusted Distributor ensures that our customers benefit from:

- Authentic NLMK Verona products with guaranteed quality

- Reliable supply chain solutions met to industry needs

- Global standards of excellence delivered locally

- On-ground technical support and grade selection support

Whether you are manufacturing dies, Molds, or critical tooling components, Virat Steels ensures your tools are built on proven European steel excellence drive productivity.

Looking Ahead

This achievement is not just a certificate— It’s a promise of authentic material, consistent quality, and strong technical partnership for the Indian tooling industry.

European tool steel excellence is now officially within reach.

Connect with Virat Special Steels to explore NLMK Verona’s authorised tool and die steel range and elevate your tooling performance.

Web: www.viratsteels.com

Email Us: info@viratsteels.com.

Ph: 98140-21775, 9999124971-80 , 9216321771-79.

NLMK Verona Tool Steel: Tough & Stable

When it comes to tool steel suppliers in India, industries demand materials of high strength, precision, and durability. Virat Steels having great experience consistently in metal domain for 7 decades bringing you the finest in European engineering—NLMK Verona Tool Steel. Known worldwide for its toughness, stability, and performance, this steel is trusted across sectors where reliability is non-negotiable.

What Makes NLMK Verona Tool Steel Exceptional?

NLMK Verona, part of the globally respected NLMK Group, is a leader in European tool steel manufacturing. Their products are engineered to hold extreme industrial conditions, ensuring longer service life and superior efficiency.

- Unmatched Toughness

- Dimensional Stability

- High Performance

Optimized for demanding applications like die-making, forging, and cutting tools.

Applications Across Industries

NLMK Verona’s tool steels are trusted in sectors where precision and durability are non-negotiable:

- Automotive Manufacturing: For molds, dies, and wear-resistant components.

- Aerospace Engineering: Ensuring stability in parts exposed to extreme conditions.

- Heavy Engineering: Industrial machinery, specialized tools.

- General Manufacturing: From injection Molds to stamping dies, performance is guaranteed.

Virat Steels: Your Trusted Tool Steel Supplier in India

Virat Steels don’t just supply steel—We deliver solutions engineered for success. By offering NLMK Verona European Tool Steel, we empower our clients with materials that defines with excellent cutting-edge metallurgy technology.

When you choose Virat Steels, you are choosing:

- Global quality with local expertise

- Quick Service

- Technical guidance to your needs

NLMK Verona’s European Tool Steel is more than just a material—it’s truly a commitment to performance. At Virat Steels, we are proud to bring this world-class steel to industries across India, ensuring that our customers stay ahead in quality and productivity.

Looking for the best tool steel suppliers in India?

Choose Virat Steels—your gateway to Italian Tool steel excellence & Discover authentic European quality with full assurance.

Meanwhile for more details explore on- https://www.viratsteels.com/

Email Us: info@viratsteels.com.

Ph: 98140 – 21775, 99991 – 24971 to 80 , 92163-21771 to 79.

Advantages of Using DIN 2714 in Modern Manufacturing

In today’s world, where sustainability and environmental responsibility have become global priorities, the manufacturing industry is evolving to adopt greener technologies and practices. A significant contributor to this shift is the strategic use of advanced materials like DIN 2714, which not only enhances performance but also offers considerable environmental benefits.

Understanding DIN 2714

DIN 2714 is a high-quality tool steel known for its excellent toughness, wear resistance, and high strength. It’s widely utilized in the forging and die-making industries to produce components that endure extreme mechanical stress. Its exceptional properties contribute to reduced waste, energy efficiency, and sustainable production processes.

Key Environmental Advantages of DIN 2714

1. Longevity and Durability:

The primary environmental advantage of DIN 2714 is its exceptional durability. Components made from this steel are resilient and maintain their structural integrity even under severe conditions. This reduces the frequency of replacements, leading to decreased consumption of raw materials and reduced waste in manufacturing. By lasting longer, DIN 2714 components contribute to a circular economy, minimizing resource depletion.

2. Energy Efficiency in Manufacturing:

The advanced metallurgical properties of DIN 2714 allow for more efficient manufacturing processes. Its high thermal resistance means fewer energy-intensive treatments are required during production. Furthermore, the improved tool performance reduces the downtime and energy associated with frequent maintenance or replacement.

3. Reduced Material Wastage:

The toughness and precision-forming capabilities of DIN 2714 ensure minimal material wastage during machining and forging operations. Manufacturers benefit from precise tolerances and reduced scrap, directly contributing to environmentally friendly production practices.

4. Recyclability:

Tool steels like DIN 2714 are highly recyclable. End-of-life products made from this steel can be melted and repurposed, conserving natural resources and minimizing the environmental impact of metal extraction. This closed-loop recycling system aligns with the goals of sustainable development and resource optimization.

5. Improved Operational Efficiency:

The enhanced performance characteristics of DIN 2714 lead to reduced machine wear and operational inefficiencies. Machines equipped with DIN 2714 components can operate for extended periods with consistent performance, translating to lower energy consumption and reduced carbon emissions.

Supporting Green Manufacturing Practices:

The use of DIN 2714 in modern manufacturing aligns seamlessly with environmentally conscious practices such as lean manufacturing and green supply chain management. Manufacturers can integrate this material into their operations to meet stringent environmental regulations and standards, such as ISO 14001. Moreover, by choosing materials like DIN 2714, companies demonstrate a commitment to environmental sustainability, bolstering their reputation in an increasingly eco-conscious market.

Conclusion

Incorporating advanced materials like DIN 2714 into modern manufacturing processes is a step forward in achieving sustainability and environmental stewardship. Its longevity, energy efficiency, recyclability, and ability to minimize waste make it a preferred choice for industries striving to reduce their carbon footprint. By adopting DIN 2714, manufacturers not only enhance operational efficiency but also contribute to a greener future for generations to come.

Virat Special Steels is proud to provide premium-grade DIN 2714 tool steel, ensuring both performance excellence and a commitment to environmental sustainability. Let’s work together to build a cleaner, greener industrial landscape.

World’s Best Premium DIN 2714 Steel Now Available in India!

India’s industrial landscape is rapidly evolving, and premium-quality steel is the backbone driving this transformation. At Virat Special Steels, we are immensely proud to be the trusted distributor and supplier of the world’s finest steel solutions, including high-grade DB6, DIN 2714 steel, designed to meet the rigorous demands of diverse industries.

Premium Steel Solutions from Leading Global Manufacturers

Virat Special Steels partners with renowned global steel manufacturers like Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals. These industry leaders are celebrated for their precision-engineered steel products, combining unparalleled durability and innovation. Now, with Virat Special Steels, Indian industries gain seamless access to these specialty long steel products, offering exceptional quality to match global standards.

Why Virat Special Steels?

1. Reliability

As an official distributor, we ensure direct access to authentic steel products from the world’s top manufacturers. Trust is the cornerstone of our business, and our transparent supply chain guarantees the highest standards of quality and authenticity.

2. Unmatched Quality

Virat Special Steels brings only the best to the table. Our product line includes high-performance steels tailored to meet the specialized needs of industries ranging from automotive and aerospace to energy and heavy machinery. Our flagship offering, DB6, DIN 2714 steel, is a testament to our commitment to quality and innovation.

3. Technical Expertise

With years of experience in the steel distribution industry, we are more than just a supplier. We offer technical insights, guidance, and customized solutions, ensuring your specific industrial requirements are met with precision.

DB6 DIN 2714 Steel: A Benchmark in Excellence

Our premium DB6, DIN 2714 steel is a game-changer, providing:

- Superior Strength: Exceptional durability ensures it stands up to the most demanding applications.

- Versatility: Perfect for forging, die-casting, and industrial tools.

- Precision Engineering: Manufactured to meet stringent global standards, it delivers unmatched performance in every use case.

Empowering Indian Industries

From automotive innovation to advanced tooling solutions, Virat Special Steels is at the forefront of enabling Indian industries to achieve new milestones. Our collaboration with the world’s leading steel manufacturers ensures that businesses in India can remain competitive on the global stage.

Choose Virat Special Steels – Your Partner in Progress

When it comes to premium-quality steel, Virat Special Steels offers unparalleled solutions tailored to the unique demands of your industry. Join us in revolutionizing India’s industrial potential with the world’s best premium steel products. Experience reliability, quality, and technical expertise, all under one roof.

Let’s build the future of India with the strength and precision of world-class steel. Reach out to Virat Special Steels today for your steel requirements!

How can I contact Virat Special Steels for inquiries or orders?

You can reach Virat Special Steels through:

- Phone: +91-98140 21775

- Email: info@viratsteels.com

- Website: www.viratsteels.com

Their offices are located in Gurgaon, Haryana, and Ludhiana, Punjab, India. For more detailed information, you can visit their official website or contact their customer service team.

Exploring DIN 2714, A Comprehensive Guide

In the industrial world, the type of steel used often defines the success of an operation. With industries increasingly relying on robust and versatile materials, steel grades like DIN 2714 have gained tremendous importance. DIN 2714 is a tool steel renowned for its exceptional mechanical properties and versatile applications. It serves as a pivotal element in numerous industrial domains, driving innovation and efficiency.

This comprehensive guide explores the composition, characteristics, and applications of DIN 2714, shedding light on why this particular steel grade is vital for modern manufacturing.

Understanding DIN 2714 Steel

DIN 2714 is classified as a hot-working tool steel, primarily known for its exceptional resistance to deformation at high temperatures. Developed in compliance with the German industrial standard, this steel stands out for its adaptability, toughness, and wear resistance, making it a favored choice for die-making industries.

Historically, the development of DIN 2714 was driven by the need for a material that could withstand extreme stress without compromising on durability. Today, it has become synonymous with reliability and performance in demanding applications.

Chemical Composition of DIN 2714

The chemical makeup of DIN 2714 significantly influences its characteristics. The main components include:

- Carbon (C): Around 0.50% to enhance hardness and strength

- Chromium (Cr): Approx. 1.2% to 2.0%, imparting wear resistance

- Manganese (Mn): Between 0.70% to 1.0%, aiding in toughness

- Silicon (Si): 0.25% to 0.40% for improved machinability

- Molybdenum (Mo): Around 0.30%, increasing high-temperature strength

- Vanadium (V): Small quantities for grain refinement

This precise composition ensures optimal mechanical properties, including high tensile strength, toughness, and durability under extreme conditions.

Physical Properties of DIN 2714 Steel

What makes DIN 2714 stand apart? Here are its key physical properties:

- Hardness: Exceptional durability ensures long-lasting performance even in abrasive conditions.

- Tensile Strength: DIN 2714 boasts a tensile strength of over 1,100 MPa, making it ideal for heavy-duty applications.

- Density: Approximately 7.85 g/cm³, offering a perfect balance of weight and toughness.

These attributes make it suitable for applications involving high pressures and temperatures, ensuring long operational lifespans.

Key Characteristics of DIN 2714

DIN 2714’s features extend beyond its composition.

- Heat Resistance: Its ability to endure high temperatures makes it ideal for hot-working environments.

- Machinability: With excellent machinability, manufacturers can shape this steel with precision, minimizing processing time.

- Weldability: Smooth weldability ensures easy integration into larger assemblies, reducing operational costs.

- Corrosion Resistance: While not highly corrosion-resistant, its treatment processes often include anti-corrosion coatings.

Common Applications of DIN 2714 Steel

DIN 2714 is used across various industries due to its versatility:

- Tool Manufacturing: Ideal for making heavy-duty forging dies, cutting tools, and machine components.

- Industrial Machinery: Widely used in presses, punches, and molds where precision and durability are critical.

- Aerospace and Automotive: Suited for high-stress components like gears and crankshafts due to its toughness.

Heat Treatment Process of DIN 2714 Steel

The heat treatment process significantly enhances the performance and durability of DIN 2714 steel, making it more suited for demanding applications. Let’s break down the stages involved:

- Annealing:

This process softens the steel to make it easier to machine. DIN 2714 steel is typically heated to a range of 820°C to 860°C and then cooled gradually in a furnace. - Hardening:

For increased strength, the steel is heated to a higher temperature range, typically between 1,020°C and 1,050°C, and then quenched in oil or water. - Tempering:

After quenching, the steel becomes brittle. Tempering at temperatures between 550°C and 650°C reduces brittleness while retaining hardness, enhancing its toughness. - Stress Relieving:

To eliminate residual stresses, DIN 2714 is reheated to approximately 600°C, maintaining structural stability during use.

The heat treatment process ensures DIN 2714 performs optimally in hot and high-pressure applications.

Comparison with Other Steel Grades

Understanding how DIN 2714 stacks up against other steel grades offers perspective on its unique benefits:

- DIN 2714 vs. EN 24 Steel:

While EN 24 is a popular alloy steel with excellent strength, DIN 2714 excels in high-temperature applications due to its superior heat resistance. - DIN 2714 vs. DIN 17350:

DIN 17350, though robust, lacks the enhanced machinability and resistance properties of DIN 2714, making it less versatile for hot-working environments.

DIN 2714 provides a balanced combination of toughness, resistance, and machinability unmatched by its counterparts.

Benefits of Using DIN 2714

DIN 2714 has numerous advantages that make it a go-to choice for industries:

- Cost-Effectiveness: Despite its premium properties, it’s reasonably priced compared to other high-performance steels.

- Versatility: Its wide range of applications, from tooling to machinery parts, highlights its adaptability.

- Durability: High resistance to wear and tear ensures fewer replacements and repairs over time, saving costs.

These benefits combine to make DIN 2714 a practical choice for manufacturers across industries.

Limitations and Challenges

Even the best materials have their limitations, and DIN 2714 is no exception:

- Limited Corrosion Resistance: While its wear and heat resistance is impressive, DIN 2714 requires proper coatings or treatments to prevent corrosion in moisture-prone environments.

- Specialized Handling: The heat treatment process demands expertise, which can increase production costs for inexperienced manufacturers.

- Specific Use Cases: Though versatile, its applications are often limited to specific industrial domains like tooling and heavy machinery.

These challenges necessitate careful planning when opting for DIN 2714 steel.

Specifications and Standards of DIN 2714

DIN 2714 complies with stringent standards, ensuring its reliability and quality:

- Chemical Composition: Strictly regulated to ensure consistent mechanical and thermal properties.

- Dimensional Standards: Meets ISO tolerances for precision in industrial applications.

- Testing Requirements: Regular quality control through tensile, hardness, and impact tests guarantees its performance under stress.

This level of compliance makes DIN 2714 a globally trusted steel grade.

Factors to Consider When Choosing DIN 2714 Steel

Selecting DIN 2714 for a specific application involves analyzing several factors:

- Application Suitability: Ensure it aligns with the demands of the job, such as high-temperature operations or heavy loads.

- Budget: While cost-effective in the long run, initial investment considerations remain essential.

- Maintenance Requirements: Plan for potential treatments or coatings to enhance durability and prevent corrosion.

By understanding these factors, manufacturers can maximize the value of using DIN 2714.

Market Demand for DIN 2714 Steel

As industries expand, the demand for reliable materials like DIN 2714 grows:

- Global Trends: Rapid industrialization in Asia and technological advancements in Europe are key drivers.

- Industry-Specific Needs: Rising reliance on automation and high-performance machinery further fuels demand.

Geographically, countries like Germany, China, and the USA lead in importing and using DIN 2714 steel, reflecting its global significance.

Sustainability and Environmental Considerations

In today’s eco-conscious world, DIN 2714’s recyclability makes it a preferred choice:

- Recycling Potential: Steel is one of the most recycled materials globally, contributing to reduced environmental impact.

- Waste Reduction: Longer lifespans mean less frequent replacements, minimizing industrial waste.

- Energy Efficiency: Advanced production techniques reduce energy consumption, making DIN 2714 an environmentally friendly option.

Adopting DIN 2714 aligns with green manufacturing goals while maintaining industrial efficiency.

Conclusion

DIN 2714 stands as a testament to innovation in the steel industry. Its unique blend of toughness, heat resistance, and machinability makes it indispensable for applications that demand durability under extreme conditions. Though it comes with challenges, its benefits far outweigh them, ensuring its place in the toolbox of manufacturers worldwide.

By understanding its properties, treatment processes, and applications, industries can fully harness the potential of DIN 2714, driving efficiency and excellence.

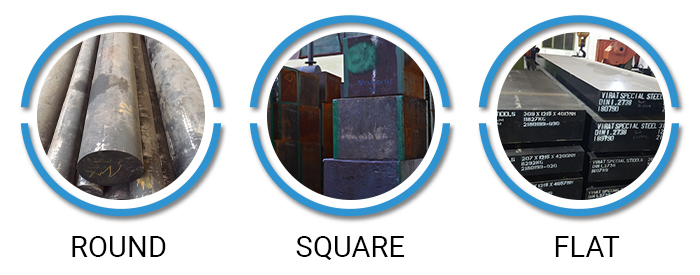

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of DIN 2714 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2714 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2714 steel query.

FAQs

- What is the primary use of DIN 2714 steel?

DIN 2714 is primarily used in tool manufacturing, particularly for forging dies and heavy-duty cutting tools. - Can DIN 2714 steel resist corrosion?

It has limited corrosion resistance and typically requires coatings or treatment for moisture-heavy environments. - How does DIN 2714 compare to other tool steels?

DIN 2714 offers superior heat resistance and machinability compared to most other tool steels, making it ideal for high-temperature applications. - What industries benefit most from DIN 2714?

Industries like automotive, aerospace, and heavy machinery manufacturing frequently use DIN 2714 for critical components. - Is DIN 2714 eco-friendly?

Yes, its recyclability and durability contribute to reducing industrial waste, making it an environmentally friendly choice.