H11

now browsing by category

What is the differences between the H11 and H13 Hot Work Steel?

If we compare between H11 and H13, H11 tool steel consists of less vanadium than the commonly used H13 hot work tool steel. This gives H11 steels the higher toughness, with some reduction in wear resistance and tamper resistance. H13 and H11 are both types of tool steels commonly used in the manufacturing and tooling industry, but they have different characteristics and applications.

Let’s compare H13 steel and H11 steel:

- Chemical Composition:

- H13 Steel: H13 is a hot work tool steel and is characterized by its high chromium content (around 5%) and molybdenum (1.4-1.75%). This composition gives it excellent heat resistance and wear resistance.

- H11 Steel: H11, on the other hand, is a hot work tool steel with a lower chromium content (around 4%) and no molybdenum. It has good toughness and heat resistance but is not as heat-resistant as H13.

- Heat Resistance:

- H13 Steel: H13 steel has excellent heat resistance, making it suitable for high-temperature applications such as die casting, forging, and extrusion.

- H11 Steel: H11 steel also offers good heat resistance, but it may not perform as well as H13 in extremely high-temperature environments.

- Toughness:

- H13 Steel: While H13 steel is tough, its primary strength lies in its heat resistance and wear resistance rather than toughness.

- H11 Steel: H11 steel is known for its toughness and is often used in applications where impact resistance is crucial, such as hammer forging and die casting.

- Applications:

- H13 Steel: H13 steel is commonly used in applications where high-temperature resistance and wear resistance are critical, including die casting dies, extrusion tools, and hot forging dies.

- H11 Steel: H11 steel is preferred for applications requiring good toughness and resistance to thermal fatigue, such as hammer and press forging, and certain types of die casting.

- Machinability:

- H13 Steel: H13 steel can be more challenging to machine due to its high hardness and heat resistance. Proper tooling and machining techniques are required.

- H11 Steel: H11 steel is generally easier to machine compared to H13, thanks to its lower hardness.

- Cost:

- H13 Steel: H13 steel is typically more expensive than H11 due to its superior heat resistance and wear resistance properties.

In summary, the choice between H13 and H11 steel depends on the specific requirements of your application. If you need high heat resistance and wear resistance, H13 may be the better choice. However, if toughness and resistance to thermal fatigue are more important, H11 could be the suitable option. Additionally, cost considerations can also influence the choice between these two tool steels.

APPLICATIONS:

Forging Dies, Punches / Dies for Extrusion on non ferrous alloys, Pressure Die Casting of Aluminium Alloys, Moulds for Thermo plastic polymer injection with high polishability. Die Inserts, Extrusion Press Tools, Forming Dies, Mandrels, Hot Shear Blades, Rolls for Hot Rolling Machines,Tools for Nuts,Screws, Bolts, Rivets, Fasteners, etc

Mode of Supply:

The Prime Supplier of Hot Work Steel in India is “VIRAT SPECIAL STEELS,” an ISO 9001:2008 certified company. Recognized globally as suppliers of quality steel they enjoy enviable affiliations with the leading producers of special steels and heavy engineering across the world. So their advice and solutions should prove invaluable in the choice of steel for different applications – such as guidance on whether H13 or H11 is better suited for your process.

Learn more:

https://www.viratsteels.com/hot-work-steel.html

https://www.viratsteels.com/h13.html

https://www.viratsteels.com/h11.html

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

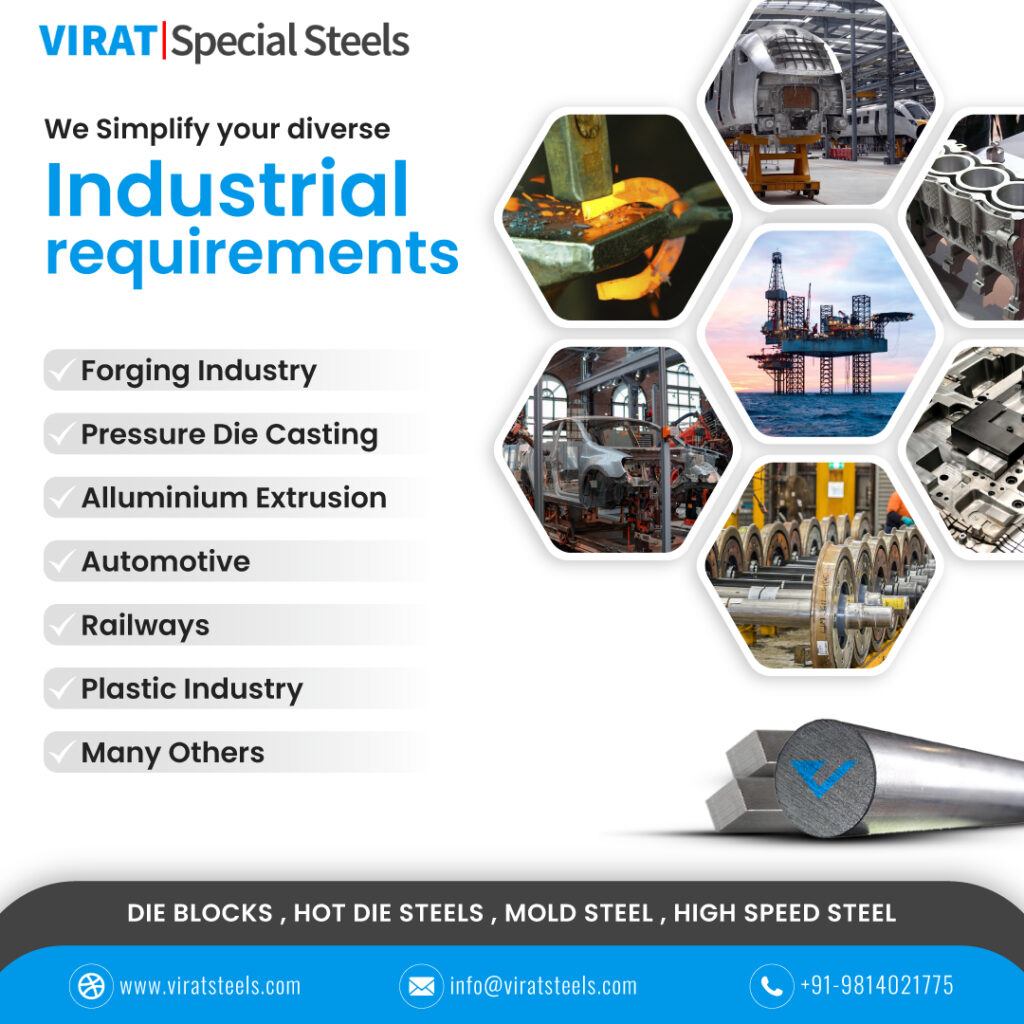

Looking for the best quality Tool Steel, Die and Mold Steels Supplier for your engineering works!

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry – Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions – In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: – Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry – Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: – Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry – Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: – DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways – They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas – Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2015 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stockist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes – Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter – Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

Feel free to contact us :

Corporate Office, #Gurgaon

Administrative Office, #Ludhiana

Email: info@viratsteels.com.

or Call us: 098140 21775

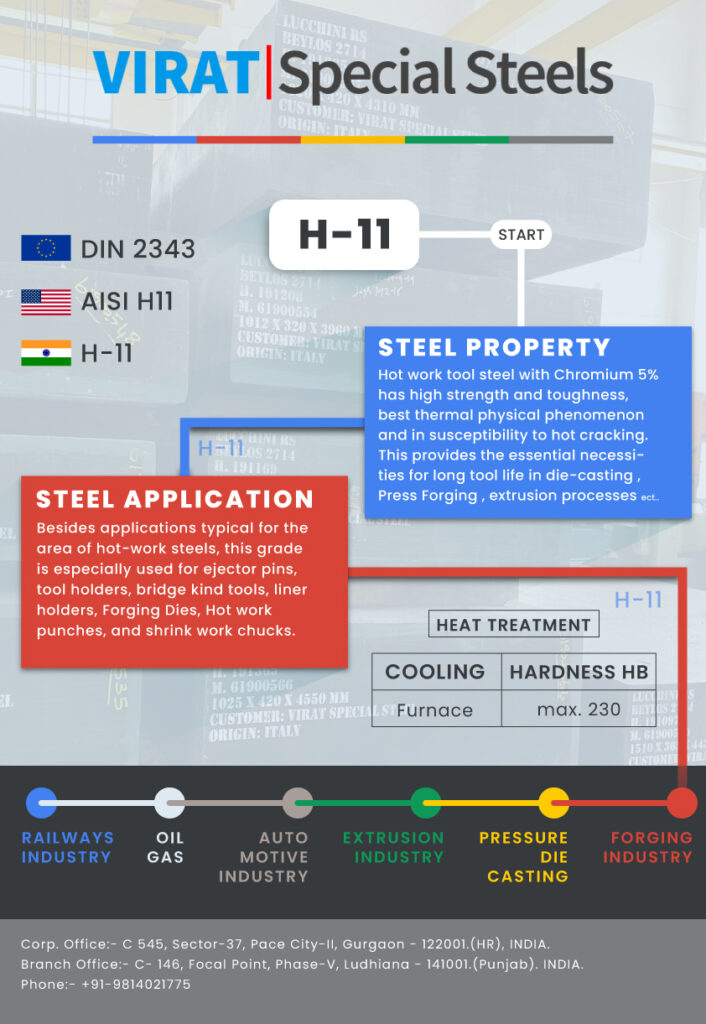

Are you looking for DIN 1.2343 Steel?

DIN 2343 | H11 | AISI H11 For hot-work steels.

This grade is especially used for ejector pins tool holders, bridge kind tools, liner holders, Forging Dies, Hot work punches, and shrink work chucks industries…

ViratSpecialSteels is the biggest & leading Supplier & Stockiest of Din 1.2343 Hot Work Steel.

Din 2343 is an all inclusive hot work tool steel with hot rigidity and durability. Good thermal conductivity and invulnerability to hot cracking can be water-cooled to a constrained degree.

Utilized for ejector pins, apparatus holders and shrink fit chucks.

Steel Properties:

Hot work tool steel with Chromium 5% has high strength and toughness, best thermal physical phenomenon and in susceptibility to hot cracking. This provides the essential necessities for long tool life in die-casting , Press Forging , extrusion processes etc.

Application:

Besides applications typical for the area of hot-work steels, this grade is especially used for ejector pins, tool holders, bridge kind tools, liner holders, Forging Dies, Hot work punches, and shrink work chucks.

Learn More:

https://www.viratsteels.com/din-2343.html

Read more:

https://www.viratsteels.com/pdf/hot-work-steels/2343.pdf

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91-9814021775