H13 Tool Steel Applications

now browsing by category

H13 Tool Steel Hardness: Methods to Test and Optimize Performance

Introduction

H13 tool steel stands out for its remarkable durability and thermal resistance, making it a preferred choice in industries such as automotive, aerospace, and manufacturing. However, its effectiveness hinges on maintaining optimal hardness, which directly impacts wear resistance, toughness, and performance under stress. This article explores various methods for testing H13 steel hardness and strategies to optimize it for maximum utility.

What is H13 Tool Steel?

H13 is a chromium-molybdenum hot work tool steel renowned for its exceptional strength and heat resistance. It contains:

- Chromium for enhanced corrosion resistance.

- Molybdenum and vanadium for superior toughness and wear resistance.

H13’s properties make it ideal for applications like:

- Forging dies.

- Injection molding tools.

- Extrusion dies.

- Die-casting components.

This robust tool steel withstands thermal fatigue, making it invaluable in environments with rapid temperature fluctuations.

Read More >Exploring Key Factors for Selecting H13 Steel for Die Applications!

Selecting the right H13 hot work tool steel for die applications involves understanding its properties, assessing your operational requirements, and choosing a reliable supplier. Its unmatched combination of toughness, thermal resistance, and durability makes it an indispensable material for demanding applications. By following the guidelines outlined in this article, you can make an informed decision that ensures optimal die performance and cost-effectiveness.

Choosing the right steel for die-making is like laying a solid foundation for a building. It’s the cornerstone that ensures durability, efficiency, and precision in manufacturing processes. Among the wide range of tool steels, H13 hot work tool steel stands out as a preferred choice for die applications. Why? Its excellent combination of toughness, temperature resistance, and durability makes it a favorite across various industries, from automotive to aerospace.

In this guide, we’ll explore everything you need to know about selecting H13 hot work tool steel for your die applications, including what makes it unique and the key factors to consider.

Understanding H13 Hot Work Tool Steel

What is H13 Steel?

H13 is a chromium-molybdenum-vanadium alloy steel, classified as a hot work tool steel. It is specially designed to endure high temperatures, resist thermal fatigue, and maintain structural integrity even under demanding conditions.

Key Properties of H13 Steel

- High Thermal Resistance: Withstands extreme heat without losing strength.

- Toughness and Durability: Handles impact and wear during heavy-duty operations.

- Thermal Conductivity: Promotes effective heat dissipation, preventing die failure.

- Wear Resistance: Resists abrasion and erosion, extending die life.

Advantages of H13 for Die Applications

H13’s balance of strength, hardness, and temperature resistance makes it ideal for hot-working operations such as forging, extrusion, and die-casting. It ensures fewer downtimes, consistent production quality, and reduced replacement costs.

Key Factors to Consider When Selecting H13 Steel for Die Applications

Temperature Resistance

The performance of dies often depends on their ability to handle extreme operating temperatures. H13 steel excels in environments where tools are exposed to temperatures up to 600°C (1112°F) or higher. Industries such as die-casting and forging heavily rely on H13 for its capacity to endure thermal cycling without cracking or deforming.

Hardness and Strength

Hardness directly influences a die’s wear resistance and operational life. H13 steel offers a Rockwell hardness range of 48-54 HRC, making it suitable for heavy-load applications. A well-balanced hardness ensures that the die can withstand repeated impacts and prolonged usage without succumbing to premature wear.

Thermal Conductivity

Heat buildup in dies can lead to dimensional changes, premature wear, and reduced production efficiency. H13’s excellent thermal conductivity ensures uniform heat distribution, which not only protects the die but also enhances the quality of the output by reducing imperfections in the finished product.

Toughness and Impact Resistance

Dies often face high pressure and sudden impacts during operations. H13 steel’s inherent toughness and impact resistance make it capable of absorbing shocks without cracking. This property is especially critical for industries such as automotive manufacturing, where precision and reliability are paramount.

Pre-Treatment and Heat Treatment of H13 Steel

The performance of H13 steel depends significantly on proper pre-treatment and heat treatment. Pre-treatment involves processes like annealing, which enhances machinability. Heat treatment, on the other hand, optimizes hardness, strength, and thermal resistance. Key heat treatment steps include hardening, tempering, and stress relieving, all tailored to the die’s intended application.

Evaluating Quality Standards for H13 Steel

To ensure you’re investing in high-quality H13 steel, look for certifications like ASTM A681 or DIN 1.2344. Premium-grade H13 steel should exhibit uniform composition, minimal impurities, and consistent mechanical properties. It’s advisable to work with reputable suppliers who provide material test certificates (MTC) to guarantee quality.

Applications of H13 Hot Work Tool Steel in Die-Making

H13 steel is used across a broad range of die-making applications, including:

- Die-Casting Dies: Withstands molten metal temperatures and repetitive cooling cycles.

- Forging Dies: Handles high-impact loads without deforming.

- Extrusion Dies: Provides excellent resistance to thermal wear and pressure.

Tips for Purchasing H13 Steel

When buying H13 steel, consider these tips:

- Source from trusted suppliers like Virat Special Steels for consistent quality.

- Verify certifications and specifications.

- Request samples or small batches for testing before large-scale purchase.

Maintenance of H13 Steel Dies

Regular maintenance can significantly extend the life of H13 steel dies. Periodic inspections help identify early signs of wear, such as cracking or pitting. Implementing proper cooling cycles and using lubricants can further enhance the die’s performance and longevity.

FAQs

- What makes H13 steel unique for die-making?

Its exceptional balance of toughness, thermal resistance, and wear resistance. - How does heat treatment impact H13 steel performance?

Heat treatment optimizes hardness and toughness, enhancing durability. - What industries benefit the most from using H13 steel?

Industries like die-casting, forging, and extrusion heavily rely on H13 steel. - How to identify high-quality H13 steel suppliers?

Look for certifications, test reports, and a proven track record of reliability. - What are the common challenges when using H13 dies?

Issues like thermal fatigue and cracking can arise if not properly maintained.

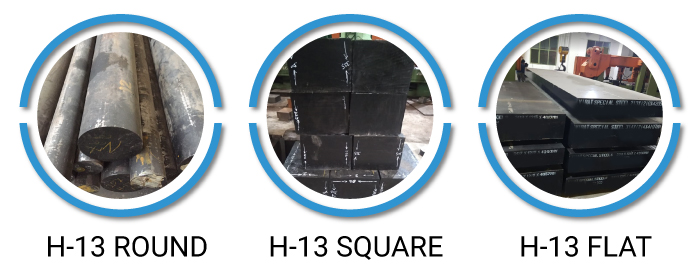

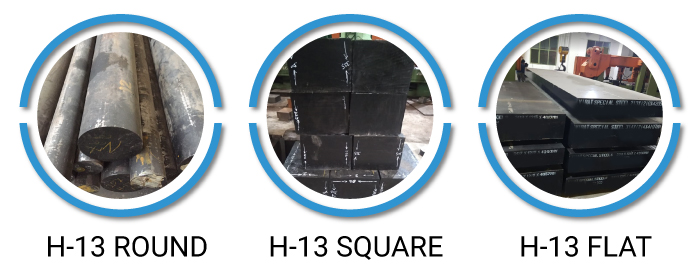

Mode of Supply:

Virat Special Steels is the largest Supplier & Stockiest of H13 Steel in India. Consult our team who will assist you for H-13/ DIN 2344 / AISI H13 steel query. https://www.viratsteels.com/h13.html

Size Range in Forged / Rolled Bars:

Rounds: 13mm Dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

For more information or to discuss your steel needs, Virat Special Steels invites you to reach out through their contact details provided, ensuring a professional and informative experience.

Any further queries feel free to contact us :

🌐https://www.viratsteel.in 📬 info@viratsteels.com ☎+91 98140-21775

H13 Steel: A Comprehensive Guide by Virat Special Steels

Overview of H13 Steel

H13 Steel is a versatile hot-work tool steel highly regarded for its durability, resistance to thermal fatigue, and exceptional strength under high temperatures. This steel type plays a vital role in various industries, from manufacturing heavy-duty dies to precision machining applications. Thanks to its unique properties, H13 Steel stands as one of the most trusted materials in both high-stress and high-temperature environments.

Significance of H13 Steel in Various Industries

Whether it’s the aerospace sector, die-making, or automotive components manufacturing, H13 Steel provides the reliability and resilience these industries demand. Virat Special Steels supplies this high-grade steel in various formats, catering to diverse business requirements. Its availability in sheets, plates, and round bars ensures clients get tailor-made solutions.

Key Features of H13 Steel

What Makes H13 Steel Unique?

H13 Steel is characterized by its:

- Exceptional heat resistance.

- High toughness and tensile strength.

- Prolonged tool life due to abrasion resistance.

These features make it ideal for forging, die-casting molds, and extrusion dies, giving manufacturers a reliable solution for high-temperature applications.

Applications of H13 Steel in the Manufacturing Sector

Industries trust H13 Steel for critical operations such as:

- Die-casting: Durable under extreme heat, making it perfect for molds.

- Automotive Tools: Precision parts for gears and shafts.

- Forging Dies: Heat-resistance for consistent long-term usage.

H13 Steel Chemical Composition and Mechanical Properties

H13 Steel Chemical Composition

The chemical composition of H13 Steel includes key elements:

| Element | Percentage |

| Carbon (C) | 0.32-0.45% |

| Chromium (Cr) | 4.75-5.50% |

| Molybdenum (Mo) | 1.10-1.75% |

| Vanadium (V) | 0.80-1.20% |

| Silicon (Si) | 0.80-1.20% |

These elements contribute to its superior heat resistance and strength.

H13 Steel Mechanical Properties

Key mechanical features of H13 Steel are:

- Hardness (HRC): 48-54.

- Tensile Strength: 2800 MPa.

- Good machinability and polishability.

H13 Steel Types and Availability

H13 Steel Plates and Sheets

Virat Special Steels offers H13 Steel plates and sheets that cater to different industrial needs, including mold manufacturing and heavy equipment production. These materials can endure extreme conditions while retaining structural integrity.

H-13 Steel Round Bar

The H-13 Steel Round Bar is a popular format used for precision machining and heavy-duty applications. Virat Special Steels ensures superior surface finish and precise dimensions in their round bars.

H-13 Steel Square and Flat Bars

Flat bars and square bars are sought-after for crafting large molds and cutting tools. Their customizable dimensions provide tailored solutions to complex engineering requirements.

H13 Steel Equivalent Grades

Exploring H13 Steel Equivalent Grades Globally

H13 Steel has global equivalents that meet different industry standards:

- AISI H13 (USA): Widely recognized in North America.

- X40CrMoV5-1 (Europe): An equivalent under European norms.

- SKD61 (Japan): Known for precise tooling applications.

Understanding these grades helps international businesses ensure consistent material quality.

H13 Steel Manufacturers and Dealers

Top H13 Steel Manufacturers in the Industry

Virat Special Steels collaborates with industry-leading manufacturers to source premium-quality H13 Steel. Their close relationships ensure superior product quality at competitive prices.

Role of H13 Steel Dealers, Distributors, and Stockists

Distributors like Virat Special Steels play a crucial role in ensuring seamless availability across industries. Their inventory spans a broad range of sheets, plates, and bars, meeting high-demand timelines.

Conclusion

H13 Steel remains an invaluable asset in modern manufacturing. From its exceptional thermal resistance to durability under stress, it equips industries with materials that stand the test of time. Choosing reliable suppliers like Virat Special Steels ensures access to top-tier products that match exact business needs.

FAQs

- What is the standard chemical composition of H13 Steel?

H13 Steel is composed of Carbon (0.32-0.45%), Chromium (4.75-5.50%), Molybdenum (1.10-1.75%), and Vanadium (0.80-1.20%). - How is H13 Steel used in die-making?

H13 Steel’s durability and heat resistance make it ideal for manufacturing extrusion and die-casting molds. - What are the benefits of choosing H-13 Steel Round Bars?

Round bars offer superior machinability, making them a top choice for crafting precision components. - Can I get H13 Steel customized for specific applications?

Yes, Virat Special Steels provides customized H13 Steel solutions to meet diverse industrial demands. - How to find trusted H13 Steel dealers near me?

Look for authorized distributors like Virat Special Steels for reliable products and timely delivery.

Locations: Based in Gurgaon (Haryana) & Ludhiana (Punjab), India.

Get in touch with us today to place your requirement!

For more information visit

https://www.viratsteels.com/h13.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Exploring H13 Tool Steel Properties, Applications and Machining!

In the world of industrial tooling, H13 tool steel stands out as a versatile and high-performance material, essential for applications requiring exceptional hardness, toughness, and resistance to thermal fatigue. At Virat Special Steels, we specialize in providing quality H13 steel and expert support to meet diverse industry needs, whether for die casting, molding, or forging applications. This blog explores the key properties, applications, and machinability of H13 tool steel, which make it a go-to solution for tooling requirements worldwide.

Understanding H13 Tool Steel

H13 tool steel is a chromium-molybdenum-vanadium alloy, specifically engineered for high-stress applications, particularly in environments with elevated temperatures. Known for its unique balance of hardness, toughness, and heat resistance, H13 is widely used in die casting and hot forging tools where it faces constant wear and thermal cycling.

Here are some of the notable properties of H13 steel that make it so valuable:

- Hot Work Capability: H13 is classified as hot work tool steel, designed to withstand high temperatures and repetitive heating and cooling cycles.

- Excellent Hardness: H13 tool steel hardness is in the range of 44-54 HRC, depending on heat treatment, which allows it to resist deformation under high-stress conditions.

- Good Toughness: H13 offers a high level of impact resistance, which is essential for tools that encounter high-pressure and high-speed operations.

- Enhanced Thermal Fatigue Resistance: The steel’s composition and structure allow it to withstand thermal cycling without cracking, which is ideal for die casting and extrusion dies.

Applications of H13 Tool Steel

Due to its ability to endure high temperatures and maintain structural integrity under stress, H13 steel is widely used across various industrial sectors.

Some of its primary applications include:

- Die Casting Dies: Its resistance to thermal fatigue and wear makes H13 ideal for molds used in die casting, where repeated exposure to molten metals demands a material that won’t degrade under high heat.

- Forging Dies: H13’s toughness and hardness are suited for hot forging, where tools must withstand high impact and compressive forces.

- Extrusion Tools: H13 is frequently used for tools involved in the extrusion of metals due to its durability and ability to withstand high-pressure environments.

- Plastic Molding Dies: In plastic molding, H13 is used for molds that need to withstand both high temperatures and pressures while producing intricate shapes.

Machining H13 Tool Steel: Tips and Techniques

Machining H13 tool steel requires specific considerations due to its hardness and toughness.

Here are some strategies that can help optimize machining processes with H13:

- Use of Carbide Tools: Given its hardness, H13 should ideally be machined with high-quality carbide cutting tools to ensure precision and reduce tool wear.

- Moderate Speeds and Feeds: For effective machining, it’s recommended to use moderate cutting speeds and feeds to prevent overheating and maintain tool integrity.

- Coolant Utilization: Applying a coolant during machining helps reduce heat build-up, especially in high-speed operations, which can protect both the tool and workpiece.

- Heat Treatment: To improve machinability, H13 is typically machined in its annealed state and then heat-treated to achieve the desired hardness for its end application.

Why Choose Virat Special Steels for H13 Tool Steel?

At Virat Special Steels, we are committed to providing top-quality H13 tool steel tailored to meet the demands of your applications. Our expertise in steel distribution, coupled with our focus on high standards and customer support, ensures that you receive only the best material, whether you need H13 die steel, mold steel, or hot work tool steel.

Our team of experts is here to help guide you through selecting the right material for your needs, offering insights on H13 material properties, mechanical properties, and recommendations for machining and heat treatment. Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website https://www.h13steel.in / https://www.viratsteels.com/h13.html

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📲 +91-98140 21775