Selecting H13 Steel for Die Applications

now browsing by category

What is H13 Steel and Its Applications?

Introduction

When it comes to materials that can withstand extreme conditions, H13 steel stands out as a top contender. This versatile chromium-molybdenum hot work tool steel is renowned for its exceptional combination of toughness, hardness, and resistance to thermal fatigue. Its unique properties make it indispensable across various industries, from automotive to aerospace.

Chemical Composition of H13 Steel

The remarkable characteristics of H13 steel are rooted in its specific chemical makeup. The typical composition includes:

- Carbon (C): 0.32 – 0.40%

- Chromium (Cr): 5.13 – 5.25%

- Molybdenum (Mo): 1.33 – 1.4%

- Vanadium (V): 1.0%

- Silicon (Si): 1.0%

- Manganese (Mn): 0.20 – 0.50%

Each element plays a pivotal role:

- Carbon enhances hardness and strength.

- Chromium improves hardenability and resistance to oxidation.

- Molybdenum increases toughness and high-temperature strength.

- Vanadium contributes to wear resistance and grain refinement.

- Silicon boosts strength and elasticity.

- Manganese aids in deoxidation during steel production.

This balanced composition ensures that H13 steel maintains its integrity under demanding conditions.

Physical Properties of H13 Steel

Understanding the physical properties of H13 steel provides insight into its performance in various applications:

- Density: Approximately 7.80 g/cm³ (0.282 lb/in³)

- Thermal Conductivity: 24.3 W/m-K at 215°C (419°F)

- Coefficient of Thermal Expansion: 11.0 µm/m-°C between 25°C and 95°C

These properties indicate that H13 steel can efficiently conduct heat while maintaining dimensional stability, crucial for tools exposed to rapid temperature changes.

Mechanical Properties of H13 Steel

The mechanical prowess of H13 steel is evident in its ability to withstand substantial stress without deformation:

- Hardness: Rockwell C scale hardness ranges from 28 to 53, depending on heat treatment.

- Tensile Strength: Ultimate tensile strength can reach up to 1990 MPa (289,000 psi).

- Toughness: Demonstrates excellent toughness, essential for resisting cracking under impact.

These attributes make H13 steel suitable for applications requiring both strength and durability.

Heat Treatment Processes for H13 Steel

To optimize its properties, H13 steel undergoes specific heat treatment processes:

- Annealing: Heating to 1550°-1650°F, holding until uniformly heated, then cooling slowly to about 1000°F to soften the steel for machining.

- Hardening: Heating to 1800°-1850°F, followed by air or oil quenching to achieve desired hardness.

- Tempering: Reheating to 1000°-1150°F, depending on the required hardness, to reduce brittleness.

These treatments enhance the steel’s performance in various applications.

Advantages of Using H13 Steel

H13 steel offers several notable benefits:

- High-Temperature Resistance: Maintains strength and hardness at elevated temperatures, making it ideal for hot work applications.

- Wear Resistance: The presence of vanadium carbides provides excellent resistance to abrasion.

- Thermal Fatigue Resistance: Can withstand repeated heating and cooling cycles without cracking.

These advantages contribute to its widespread use in demanding environments.

Applications

1. Applications in Hot Work Tooling

H13 steel is widely used in hot work tooling applications where materials are subjected to high temperatures and extreme mechanical stress. Some of its key applications in this domain include:

- Die Casting Dies: H13 steel is commonly used for die-casting dies due to its excellent heat resistance, wear resistance, and toughness. The ability to withstand the rapid heating and cooling cycles involved in die-casting operations ensures longer tool life.

- Extrusion Dies: In aluminum and other metal extrusion processes, H13 steel is used to manufacture dies that shape and form metal billets. The steel’s strength and thermal stability prevent premature wear and deformation.

- Forging Dies: H13 steel is used in the production of forging dies that shape metal parts through high-pressure impacts. The toughness and heat resistance of H13 help the dies maintain their shape under extreme conditions.

These applications make H13 an indispensable material in the hot work tooling industry, ensuring efficiency, precision, and durability.

2. Applications in Cold Work Tooling

Although primarily known for hot work applications, H13 steel also finds limited usage in cold work tooling where wear resistance and impact strength are required. Some examples include:

- Shear Blades: H13 steel is used for manufacturing shear blades that cut or trim metal sheets, where its hardness and durability contribute to precision and long service life.

- Stamping Dies: H13 is occasionally used in stamping dies for cold-forming applications, where its wear resistance helps maintain die integrity.

- Plastic Molds: While more common in hot work environments, H13 is also used for plastic injection molding where high strength and heat resistance are necessary.

Although other cold work steels like D2 or O1 may be preferred for most cold work applications, H13’s versatility allows it to be used where both wear resistance and toughness are required.

3. Use in Plastic Injection Molding

H13 steel is one of the top choices for plastic injection molding tools, particularly for mold inserts. Some advantages include:

- High Thermal Conductivity: Ensures efficient heat dissipation, reducing cycle times and improving productivity.

- Wear and Corrosion Resistance: Prevents mold degradation, ensuring longevity and consistent production quality.

- Dimensional Stability: H13 maintains its structure under high pressure and temperature, reducing warping and defects in molded parts.

These properties make H13 a preferred material for injection molding applications, where durability and precision are critical.

4. H13 Steel in the Automotive Industry

The automotive sector relies on H13 steel for various high-performance applications. Some of the most common uses include:

- Engine Components: H13 steel is used in manufacturing engine components such as cylinder heads, pistons, and exhaust valves, where high-temperature resistance is necessary.

- Structural Parts: Some automotive manufacturers use H13 in critical structural components that must withstand mechanical and thermal stress.

- Tooling for Manufacturing: Many of the dies and molds used in automotive production, including stamping dies and injection molds, are made from H13 steel.

The exceptional properties of H13 steel help improve the durability and performance of automotive parts and manufacturing processes.

5. H13 Steel in the Aerospace Industry

The aerospace industry demands materials with superior strength, heat resistance, and toughness. H13 steel meets these requirements and is used in:

- Turbine Blades: Due to its heat resistance, H13 is used in manufacturing certain aerospace turbine components exposed to high temperatures.

- Structural Components: Some aerospace structures, including landing gear and support brackets, benefit from the toughness of H13 steel.

With the aerospace industry constantly pushing for high-performance materials, H13 remains a strong candidate for demanding applications.

Conclusion

H13 steel is a versatile and high-performance material used in numerous industries, including automotive, aerospace, die-casting, and injection molding. Its unique combination of high-temperature resistance, wear resistance, and toughness makes it an ideal choice for hot work tooling and other demanding applications. While it has some limitations, proper heat treatment and machining techniques help maximize its benefits. Whether in the production of industrial tools, aerospace components, or plastic molds, H13 remains a top-tier tool steel for high-performance applications.

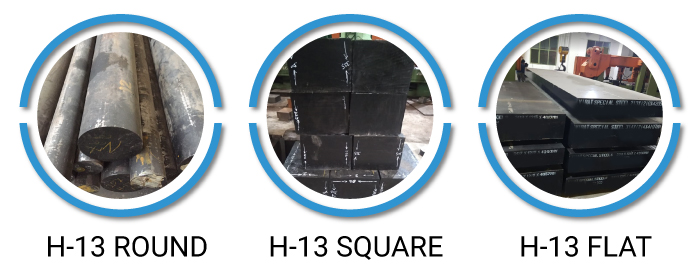

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

FAQs

1. What makes H13 steel suitable for high-temperature applications?

H13 steel has excellent thermal fatigue resistance, high wear resistance, and superior toughness, making it ideal for high-temperature applications such as die casting and forging.

2. How does H13 steel compare to D2 tool steel?

H13 is better suited for high-temperature applications, while D2 is a cold work steel with superior wear resistance. Choosing between them depends on whether heat resistance or abrasion resistance is a priority.

3. Can H13 steel be welded?

Yes, H13 steel can be welded, but it requires preheating and post-weld heat treatment to prevent cracking and ensure structural integrity.

4. What industries commonly use H13 steel?

H13 steel is widely used in die-casting, plastic injection molding, aerospace, automotive manufacturing, and hot work tooling applications.

5. How does heat treatment affect H13 steel?

Proper heat treatment enhances H13 steel’s hardness, strength, and resistance to thermal fatigue, ensuring optimal performance in demanding applications.

What Industries Benefit the Most from Using H13 Steel?

Introduction

In the vast world of industrial materials, few tool steels have made as significant an impact as H13 steel. Renowned for its exceptional durability, heat resistance, and machinability, H13 steel stands as a cornerstone in industries requiring high-performance materials. From automotive manufacturing to plastic molding, this versatile steel helps businesses thrive by enhancing productivity and ensuring long-term efficiency.

Whether you’re an industry expert or a curious reader, understanding the benefits and applications of H13 steel sheds light on why it is so widely celebrated. Let’s explore what makes H13 steel an indispensable choice for various industries.

Understanding H13 Steel

What Is H13 Steel?

H13 steel is a chromium-molybdenum hot-work tool steel that offers exceptional strength and resistance to thermal fatigue. Classified as an H-grade steel, it is specially engineered for high-temperature applications. Its unique composition includes:

- Carbon: Provides hardness.

- Chromium and Molybdenum: Enhance toughness and heat resistance.

- Vanadium: Adds wear resistance.

Unique Characteristics of H13 Steel

H13 steel’s distinguishing properties make it one of the most trusted materials for heavy-duty industrial purposes:

- High thermal stability and resistance to cracking under thermal cycling.

- Exceptional machinability and ease of finishing.

- Outstanding toughness and abrasion resistance.

Common Applications in Industry

From manufacturing molds to constructing durable tools, H13 steel has applications across various demanding environments. It’s especially suited for high-heat tasks, such as die-casting and injection molding.

The Importance of H13 Steel in Industrial Sectors

In today’s competitive market, industries are constantly on the lookout for materials that can endure intense conditions without compromising efficiency. H13 steel has earned a reputation for its ability to reduce downtime and extend the lifespan of tools. Its versatility and reliability allow companies to deliver products that meet rigorous performance standards.

Industries That Benefit the Most from H13 Steel

Automotive Industry

The automotive sector thrives on precision and durability, and H13 steel plays an integral role in achieving these goals. The material’s heat resistance and toughness make it a prime choice for:

- Die-casting molds: Creating engine parts and automotive components.

- High-temperature tools: Handling demanding manufacturing processes without deforming or cracking.

Aerospace Industry

Aviation demands high precision and reliability. H13 steel contributes to the aerospace industry by being an ideal material for:

- Forging dies and cutting tools.

- Heat-treated aviation components that endure extreme stress and temperature changes.

Plastic Molding and Manufacturing

In the realm of plastic production, injection molds are under constant pressure to perform efficiently. H13 steel ensures the longevity and quality of:

- Injection molds: That shape plastics for consumer goods.

- Tooling parts: That resist wear from continuous production cycles.

Die-Casting Industry

The die-casting sector relies heavily on H13 steel for its ability to withstand molten metals. It’s an essential material for:

- High-performance casting molds for aluminum, zinc, and magnesium.

- Precision tools that resist thermal cycling and erosion.

Construction and Heavy Equipment

Heavy industries demand tools and parts that endure tremendous mechanical stress. H13 steel finds its place in:

- Specialized construction machinery parts.

- Tools used in mining and heavy lifting.

Benefits of Using H13 Steel for These Industries

- High Heat Resistance: Maintains its shape and properties under extreme temperatures.

- Durability and Toughness: Resists deformation and cracking under heavy loads.

- Cost Efficiency: Reduces tool replacements and downtime, saving companies money in the long run.

Challenges in Using H13 Steel

Like all materials, H13 steel has challenges:

- Machining Difficulties: Requires skilled handling for optimal results.

- Heat Treatment Needs: Proper treatment is necessary to ensure performance.

- Cost Considerations: While initial costs are high, long-term savings often outweigh this drawback.

Tips for Selecting and Maintaining H13 Steel

- Choose Trusted Suppliers: Ensure quality by sourcing H13 steel from reliable manufacturers like Virat Special Steels.

- Prioritize Heat Treatment: Proper treatment enhances longevity and performance.

- Regular Maintenance: Periodically inspect tools and parts to ensure optimal operation.

Virat Special Steels: A Leader in H13 Steel Supplies

Virat Special Steels is a renowned name in delivering high-quality tool steels, including H13. With decades of industry expertise, Virat has built a reputation for reliability and superior service. Industries across automotive, aerospace, and plastic molding trust Virat for their steel requirements.

Future Trends and Applications of H13 Steel

Advancements in technology continue to unlock new applications for H13 steel, from cutting-edge aerospace innovations to enhanced 3D printing tools. As industries demand more from their materials, H13 steel is expected to remain a cornerstone of industrial growth.

Conclusion

H13 steel is a true industrial powerhouse, serving as a backbone for industries requiring unmatched durability and heat resistance. Its applications across automotive, aerospace, die-casting, and more make it indispensable in achieving quality and performance. For businesses looking to enhance their productivity, H13 steel, supplied by trusted names like Virat Special Steels, remains a wise investment.

FAQs

1. What sets H13 steel apart from other tool steels?

H13 steel offers unmatched heat resistance and durability, making it ideal for high-temperature and high-stress applications.

2. How does H13 steel contribute to cost savings in industries?

Its long lifespan reduces the need for frequent replacements, saving money over time.

3. Can H13 steel be recycled for industrial use?

Yes, H13 steel is recyclable, contributing to sustainable industrial practices.

4. What types of maintenance are needed for H13 steel tools?

Regular inspections, timely heat treatments, and cleaning to avoid contamination can ensure prolonged efficiency.

5. Where can industries procure high-quality H13 steel?

Reliable suppliers like Virat Special Steels specialize in delivering premium-grade H13 steel for diverse industrial needs.

Virat Special Steels is the largest Supplier & Stockiest of H13 Steel in India. Consult our team who will assist you for H-13/ DIN 2344 / AISI H13 steel query. https://www.viratsteels.com/h13.html

Size Range in Forged / Rolled Bars:

Rounds: 13mm Dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

For more information or to discuss your steel needs, Virat Special Steels invites you to reach out through their contact details provided, ensuring a professional and informative experience.

Any further queries feel free to contact us :

🌐https://www.viratsteel.in 📬 info@viratsteels.com ☎+91 98140-21775

Exploring Key Factors for Selecting H13 Steel for Die Applications!

Selecting the right H13 hot work tool steel for die applications involves understanding its properties, assessing your operational requirements, and choosing a reliable supplier. Its unmatched combination of toughness, thermal resistance, and durability makes it an indispensable material for demanding applications. By following the guidelines outlined in this article, you can make an informed decision that ensures optimal die performance and cost-effectiveness.

Choosing the right steel for die-making is like laying a solid foundation for a building. It’s the cornerstone that ensures durability, efficiency, and precision in manufacturing processes. Among the wide range of tool steels, H13 hot work tool steel stands out as a preferred choice for die applications. Why? Its excellent combination of toughness, temperature resistance, and durability makes it a favorite across various industries, from automotive to aerospace.

In this guide, we’ll explore everything you need to know about selecting H13 hot work tool steel for your die applications, including what makes it unique and the key factors to consider.

Understanding H13 Hot Work Tool Steel

What is H13 Steel?

H13 is a chromium-molybdenum-vanadium alloy steel, classified as a hot work tool steel. It is specially designed to endure high temperatures, resist thermal fatigue, and maintain structural integrity even under demanding conditions.

Key Properties of H13 Steel

- High Thermal Resistance: Withstands extreme heat without losing strength.

- Toughness and Durability: Handles impact and wear during heavy-duty operations.

- Thermal Conductivity: Promotes effective heat dissipation, preventing die failure.

- Wear Resistance: Resists abrasion and erosion, extending die life.

Advantages of H13 for Die Applications

H13’s balance of strength, hardness, and temperature resistance makes it ideal for hot-working operations such as forging, extrusion, and die-casting. It ensures fewer downtimes, consistent production quality, and reduced replacement costs.

Key Factors to Consider When Selecting H13 Steel for Die Applications

Temperature Resistance

The performance of dies often depends on their ability to handle extreme operating temperatures. H13 steel excels in environments where tools are exposed to temperatures up to 600°C (1112°F) or higher. Industries such as die-casting and forging heavily rely on H13 for its capacity to endure thermal cycling without cracking or deforming.

Hardness and Strength

Hardness directly influences a die’s wear resistance and operational life. H13 steel offers a Rockwell hardness range of 48-54 HRC, making it suitable for heavy-load applications. A well-balanced hardness ensures that the die can withstand repeated impacts and prolonged usage without succumbing to premature wear.

Thermal Conductivity

Heat buildup in dies can lead to dimensional changes, premature wear, and reduced production efficiency. H13’s excellent thermal conductivity ensures uniform heat distribution, which not only protects the die but also enhances the quality of the output by reducing imperfections in the finished product.

Toughness and Impact Resistance

Dies often face high pressure and sudden impacts during operations. H13 steel’s inherent toughness and impact resistance make it capable of absorbing shocks without cracking. This property is especially critical for industries such as automotive manufacturing, where precision and reliability are paramount.

Pre-Treatment and Heat Treatment of H13 Steel

The performance of H13 steel depends significantly on proper pre-treatment and heat treatment. Pre-treatment involves processes like annealing, which enhances machinability. Heat treatment, on the other hand, optimizes hardness, strength, and thermal resistance. Key heat treatment steps include hardening, tempering, and stress relieving, all tailored to the die’s intended application.

Evaluating Quality Standards for H13 Steel

To ensure you’re investing in high-quality H13 steel, look for certifications like ASTM A681 or DIN 1.2344. Premium-grade H13 steel should exhibit uniform composition, minimal impurities, and consistent mechanical properties. It’s advisable to work with reputable suppliers who provide material test certificates (MTC) to guarantee quality.

Applications of H13 Hot Work Tool Steel in Die-Making

H13 steel is used across a broad range of die-making applications, including:

- Die-Casting Dies: Withstands molten metal temperatures and repetitive cooling cycles.

- Forging Dies: Handles high-impact loads without deforming.

- Extrusion Dies: Provides excellent resistance to thermal wear and pressure.

Tips for Purchasing H13 Steel

When buying H13 steel, consider these tips:

- Source from trusted suppliers like Virat Special Steels for consistent quality.

- Verify certifications and specifications.

- Request samples or small batches for testing before large-scale purchase.

Maintenance of H13 Steel Dies

Regular maintenance can significantly extend the life of H13 steel dies. Periodic inspections help identify early signs of wear, such as cracking or pitting. Implementing proper cooling cycles and using lubricants can further enhance the die’s performance and longevity.

FAQs

- What makes H13 steel unique for die-making?

Its exceptional balance of toughness, thermal resistance, and wear resistance. - How does heat treatment impact H13 steel performance?

Heat treatment optimizes hardness and toughness, enhancing durability. - What industries benefit the most from using H13 steel?

Industries like die-casting, forging, and extrusion heavily rely on H13 steel. - How to identify high-quality H13 steel suppliers?

Look for certifications, test reports, and a proven track record of reliability. - What are the common challenges when using H13 dies?

Issues like thermal fatigue and cracking can arise if not properly maintained.

Mode of Supply:

Virat Special Steels is the largest Supplier & Stockiest of H13 Steel in India. Consult our team who will assist you for H-13/ DIN 2344 / AISI H13 steel query. https://www.viratsteels.com/h13.html

Size Range in Forged / Rolled Bars:

Rounds: 13mm Dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

For more information or to discuss your steel needs, Virat Special Steels invites you to reach out through their contact details provided, ensuring a professional and informative experience.

Any further queries feel free to contact us :

🌐https://www.viratsteel.in 📬 info@viratsteels.com ☎+91 98140-21775