November, 2024

now browsing by month

Did you know about the Steel Facts?

Steel is one of the most widely used materials in the world, found in everything from buildings and bridges to cars and household appliances. Steel is 100% recyclable without any loss of quality.

But what happens when steel products reach the end of their life cycle in all these applications?

Actually, it’s not the end. Indeed, for steel there is no end, as steel is 100% and infinitely recyclable without any loss of quality. The steel in end-of-life products can be melted down to be reused in the production of new steel.

This involves several stages:

- Collection: A significant amount of scrap currently used in steelmaking processes is acquired before it reaches the marketplace. Known as prompt scrap, these are residuals of large-scale industrial manufacturing processes

- Sorting: Scrap needs to be sorted and separated based on type and quality. As steel is made from a mix of various alloys and materials, such as carbon, chromium, manganese, nickel, and others, you need to match the steel grade you want to produce with scrap that matches its properties.

- Shredding: Once sorted, large scrap metal pieces are fed into industrial shredders, which break them into smaller pieces.

- Melting and refining: The shredded scrap steel is then placed into furnaces and melted down at temperatures that can exceed 1,600°C (2,900°F), turning the steel into molten metal.

- Casting and rolling: The refined steel is then poured into moulds, cooled, and rolled into new steel products, such as sheets, bars, or beams, ready to be used as they are or to be further processed into other products.

The study delves into the value of reestablishing compositional information for steel recycling and sheds light on the dynamic nature of steel grades.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA Your Trusted Partner in Special Steels. Explore a vast inventory of Die Blocks and Tool Steels sourced from renowned manufacturers worldwide…

Our Steel Yards boast a comprehensive inventory, including:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Learn more :

https://www.viratsteels.com/

Any further queries feel free to contact us :

📩info@viratsteels.com 📲+91-98140-21775

Crafting Excellence with Virat Special Steels

When it comes to strength, durability, and unparalleled precision, Virat Special Steels stands tall as an industry leader. Combining state-of-the-art technology, innovative craftsmanship, and an unwavering commitment to quality, Virat redefines steel processing. From cutting-edge bandsaw machines to maintaining the largest steel yards stocked with premium grades of special steels, Virat ensures every customer gets nothing short of excellence.

Let’s dive deeper into why Virat Special Steels is your ultimate partner for steel processing needs.

Introduction to Virat Special Steels

Virat Special Steels has cemented its place as a trusted name in steel processing. With decades of experience and an unwavering commitment to innovation, the company continues to set benchmarks in the industry. Whether it’s about delivering high-grade steel or ensuring cutting precision with bandsaw technology, Virat is synonymous with reliability and performance.

Unmatched Durability and Precision

At Virat, durability isn’t just a promise; it’s a standard. Every product and service offered by the company is tailored to meet the most rigorous demands. Whether you’re working on massive industrial projects or intricate designs, Virat ensures strength and precision every step of the way.

Their motto? “When it’s about durability, strength, and precision – it’s Virat!“

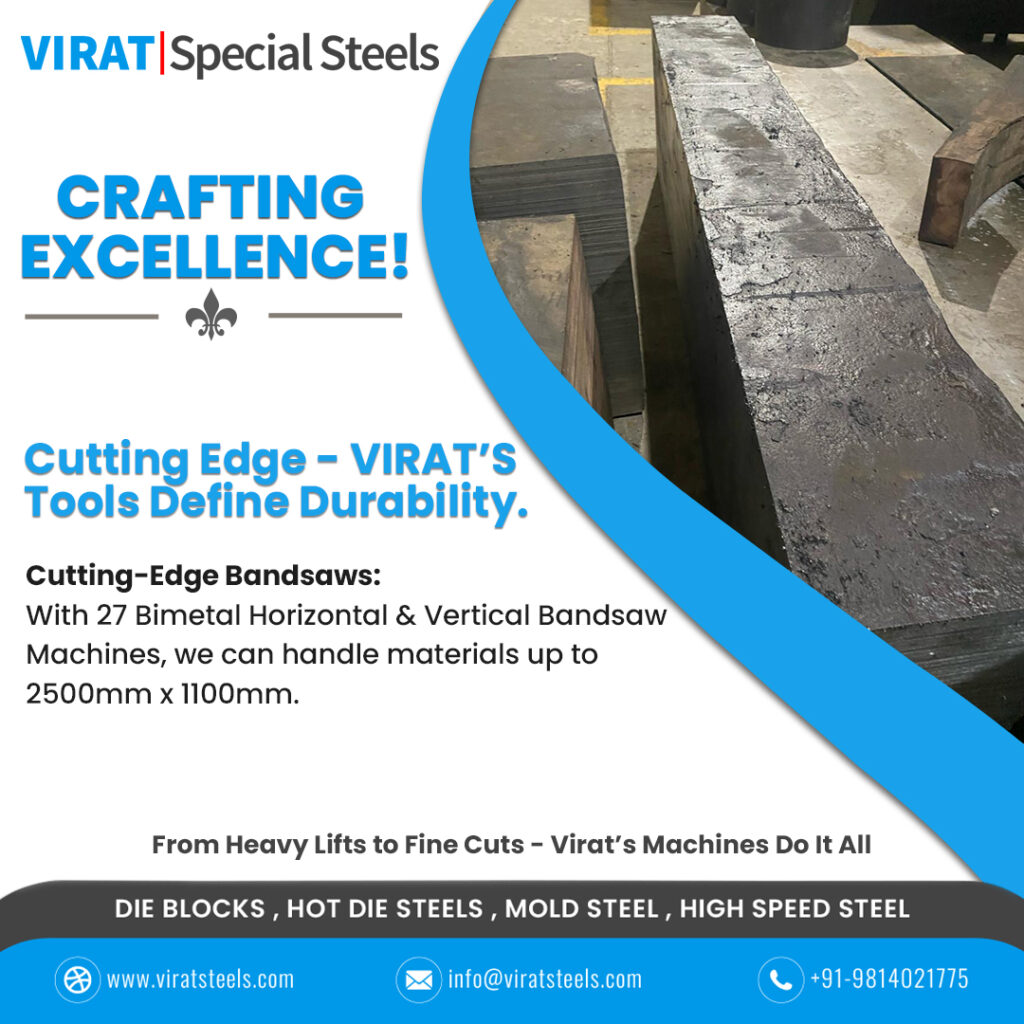

Cutting-Edge Bandsaw Technology:

Features of Virat’s Bandsaw Machines: Virat Special Steels takes pride in its 27 state-of-the-art bi-metal horizontal and vertical bandsaw machines. These machines are equipped with advanced features to ensure:

- Exceptional Cutting Precision: Cut through a wide variety of materials with unparalleled accuracy.

- Impressive Material Handling Capacity: Able to handle dimensions as large as 2500 mm x 1100 mm.

- Efficiency and Speed: Delivering quick results without compromising quality.

- Versatility: Perfect for various industrial applications.

Handling Large-Scale Materials with Ease

Large-scale industrial projects demand equipment that can handle significant workloads. Virat’s bandsaws rise to the challenge by ensuring efficient cutting of oversized materials, reducing lead times, and enhancing productivity.

Why Choose Virat Special Steels?

Expertise in Steel Processing: With a team of skilled professionals and decades of experience, Virat is equipped to handle complex steel processing projects with ease.

Focus on Quality and Innovation

The company’s commitment to quality and innovation is evident in its use of cutting-edge technology and its dedication to customer satisfaction.

- What makes Virat’s bandsaw machines stand out?

Virat’s bandsaw machines are equipped with advanced technology that ensures precision, speed, and efficiency. They can handle large materials and deliver unmatched results. - What types of steels does Virat offer?

Virat specializes in tool steels, die steels, alloy steels, and other special grades like DIN 2714, DB6, H13, and H11. - How large are the materials Virat can process?

Virat’s bandsaw machines can handle materials as large as 2500 mm x 1100 mm, making them suitable for heavy-duty industrial projects. - Why should I choose Virat for my steel processing needs?

Virat offers a combination of cutting-edge technology, high-quality materials, and exceptional expertise, ensuring precision and durability in every project. - How can I get in touch with Virat Special Steels?

You can contact Virat through their official website (www.viratsteels.com) or reach out to their team directly to discuss your requirements and place an order.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels like … DIN 2714, DB6, H13, H11, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteel.in/special-steel-supply-networks/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91-9814021775

Exploring the Versatility of H13 Tool Steel: Virat Special Steels

In the world of metallurgy, H13 tool steel stands out for its exceptional performance in challenging environments. Virat Special Steels, a leader in the steel industry, is renowned for its high-quality H13 steel, which is a hot work tool steel with a unique balance of toughness, resistance to thermal fatigue, and high red hardness.

H13 tool steel is an alloy that is widely used in die-casting and molding due to its ability to withstand rapid cooling and heating cycles. This makes it an ideal material for tools and dies used in the automotive, aerospace, and plastic molding industries. The steel’s composition includes elements such as chromium, molybdenum, and vanadium, which contribute to its hardenability and stability under high temperatures.

One of the key properties of H13 steel is its excellent resistance to thermal shock, which is crucial for tools that operate under extreme heat conditions. The H13 die steel variant is specifically designed to offer high wear resistance and toughness, ensuring a longer service life for dies in high-pressure die casting.

For mold applications, H13 mold steel provides a polished surface finish, essential for high-quality end products. The hot die steel H13 variant is tailored for forging dies, extrusion dies, and other applications where the steel must perform reliably at elevated temperatures.

The hardness of H13 tool steel is another significant attribute, with the material achieving an optimal balance between hardness and ductility. This balance ensures that the steel can be machined effectively without compromising its structural integrity. The H13 material properties include a uniform and high level of toughness, which helps in preventing cracking or breaking under stress.

Virat Special Steels takes pride in offering H13 steel with consistent mechanical properties, ensuring that each batch meets the stringent requirements of their clients. The H13 raw material hardness is carefully controlled during the manufacturing process, resulting in a product that can be relied upon for its performance and durability.

Machining H13 tool steel requires expertise, as the material’s hardness can pose challenges. However, with the right techniques and tools, H13 can be shaped and finished to meet precise specifications, making it a versatile choice for a wide range of industrial applications.

In conclusion, H13 tool steel is a material that offers a remarkable combination of toughness, wear resistance, and the ability to withstand high temperatures. Virat Special Steels‘ commitment to quality ensures that their H13 steel products are at the forefront of the industry, providing reliable solutions for the most demanding applications. Whether it’s for die casting, mold making, or hot work tooling H13 steel from Virat Special Steels is a material that can be trusted to perform.

D2 vs D3 Steel: Key Differences

When it comes to tool steels, D2 and D3 are two of the most commonly used grades in the industry. Both are high-carbon, high-chromium steels known for their durability and wear resistance, making them ideal for various cutting, shaping, and forming applications. However, despite their similarities, there are distinct differences that can significantly impact their performance in different environments.

D2 steel is renowned for its high wear resistance and ability to retain a sharp edge, which is attributed to its 1.5-2% carbon and 12-14% chromium content. It also contains small amounts of manganese, molybdenum, silicon, and vanadium, which contribute to its overall toughness and hardenability. D2’s hardness after heat treatment typically reaches 60-62 HRC, providing a good balance between hardness and toughness for many applications.

On the other hand, D3 steel, with its 1.9-2.3% carbon and 12-14% chromium content, offers slightly different properties. It includes small amounts of manganese, molybdenum, silicon, nickel, and copper, which enhance its wear and abrasion resistance. D3 is known to perform better in extreme temperatures and retains its hardness, reaching 63-65 HRC after heat treatment, which is slightly higher than D2.

Edge retention is another critical factor where D2 excels due to its higher carbon content, although D3 can achieve similar levels with proper heat treatment. Corrosion resistance is a shared strength between the two, thanks to their high chromium content, but D3 edges out slightly due to its higher nickel content, offering enhanced corrosion resistance.

In terms of machinability, D3 is considered to have better machinability compared to D2, which can be more challenging to machine due to its abrasiveness and hardness. This makes D3 a more suitable option for applications that require extensive machining.

Ultimately, the choice between D2 and D3 steel will depend on the specific requirements of the project. Factors such as the desired balance between hardness and toughness, wear resistance needs, and machining considerations will play a crucial role in determining the most suitable steel grade. Consulting with metallurgical experts and considering the application’s unique demands will ensure the selection of the right steel for optimal performance and longevity.

For those interested in a more in-depth comparison, further information can be found in detailed analyses provided by industry experts. Understanding these key differences will aid professionals in making informed decisions that align with their project’s goals and budget constraints. Whether it’s for cutting tools, punches, dies, or other demanding applications, choosing the right steel is essential for achieving the desired outcomes in metalworking projects.

Virat Special Steels is the largest stockiest and supplier of HCHCR D2 and HCHCR D3 Steel in flat, square and round bar. We provide steel in all sizes as your requirements. HCHCR D2 and HCHCR D3 die steel is available in flat, square and round shape. Consult our team who will assist you for HCHCR D2/D3 steel query.

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📩info@viratsteels.com 📲+91-98140-21775

VMO Steel The Superior Choice for High-Performance Hot Work Applications!

What Is VMO Steel?

VMO steel, also known as ABNT VMO, is a specialized hot work tool steel grade renowned for its high-strength properties, resilience under extreme temperatures, and superior wear resistance. Developed with a specific focus on hot work applications, VMO steel is particularly well-suited for forging dies used in high-performance drop hammers. Its meticulously balanced chemical composition and excellent mechanical properties give it a significant edge in maintaining performance and integrity, even under the harshest conditions.

Key Applications of VMO Steel in Industry

- Forging Dies for Drop Hammers: VMO steel is designed to withstand the extreme pressure and high temperatures encountered during drop forging, ensuring consistent performance and durability.

- Hot Work Tooling: Its resistance to thermal fatigue makes VMO an ideal choice for various hot work tools, such as molds and dies for die casting.

- High-Temperature Industrial Processes: VMO steel is favored in applications that demand both strength and heat resistance, making it suitable for use in high-temperature industrial machinery and equipment.

Why Choose VMO Steel?

For industry professionals, material choice is crucial to achieving superior performance and maintaining product longevity.

Here’s why VMO steel emerges as a top choice in its class:

- Superior Strength & Toughness: Ideal for Demanding Environments

VMO steel is engineered for environments that require a balance of strength and toughness. Unlike standard tool steels, VMO can withstand the high impact and pressure of drop forging without compromising its structural integrity. - High Impact Resistance: VMO’s composition includes a blend of elements that enhance its ability to absorb shock, making it particularly useful for impact-intensive applications like drop forging.

- Structural Durability: Even when subjected to repeated heavy loads, VMO steel maintains its shape and effectiveness, reducing the need for frequent replacement or repair of tooling equipment.

- Enhanced Fatigue Resistance: VMO steel’s robustness ensures it resists the cyclic stresses that can lead to early material failure in other grades, extending the life of critical components.

Comparing VMO Steel with Other Hot Work Tool Steels

For those in industries requiring hot work tools, understanding the comparative advantages of VMO steel over other tool steels can guide better material selection.

| Property | VMO Steel | Standard Hot Work Steel (H13) | Standard Cold Work Steel |

| Temperature Resistance | Excellent | Good | Limited |

| Impact Resistance | High | Moderate | Low |

| Wear Resistance | Excellent | Moderate | High |

| Thermal Fatigue Resistance | Very High | High | Low |

| Ideal Applications | Hot Forging, Drop Hammers | Die Casting, Molds | Tooling, Punching |

Virat Special Steels has launched a groundbreaking steel grade—VMO, also known as ABNT VMO—designed to excel in high-temperature, high-performance applications. Engineered to meet the rigorous demands of hot work operations, this specialized steel stands out as a go-to material for forging dies, especially for high-stress, high-impact drop hammers. With its exceptional strength, durability, and performance, VMO steel promises to redefine industry standards for professionals who rely on reliable and resilient materials in challenging environments.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your VMO Steel experience quality and reliability.

Upgrade your tools and dies with the best in the industry! Contact us today to learn more about how VMO steel can enhance your operations.

Contact us today to learn more!

https://www.viratsteel.in/products/vmo-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Understanding the Mechanical Properties of High Carbon Steel!

High carbon steel is renowned for its exceptional mechanical properties, making it a vital material in various industrial applications. At Virat Special Steels, we recognize the significance of these properties and ensure the highest quality standards in our high carbon steel offerings.

High-carbon steel has approximately 0.6 to 1.0% carbon content. It is very strong, used for springs, edged tools, and high-strength wires. Discover Quality Die Steel with Virat Special Steels Pvt. Limited. As the leading die steel supplier in India, Virat Special Steels Pvt. Limited takes pride in delivering exceptional quality and reliability.

Let’s delve into the key mechanical properties that make high carbon steel an indispensable material in manufacturing and engineering.

- High Strength : One of the most notable properties of high carbon steel is its high strength. This material has a high tensile strength, which means it can withstand significant stress and strain without deforming. This makes it ideal for applications requiring robust and durable materials, such as cutting tools, blades, and springs.

- Hardness: High carbon steel is known for its superior hardness compared to low or medium carbon steel. This hardness is achieved through heat treatment processes such as quenching and tempering. The increased hardness makes high carbon steel resistant to wear and abrasion, making it suitable for high-stress applications like industrial machinery and cutting tools.

- Wear Resistance: The wear resistance of high carbon steel is another critical property that makes it suitable for demanding applications. The high carbon content enhances the steel’s ability to resist surface wear and tear, extending the lifespan of components made from this material. This is particularly important in the manufacturing of tools and machinery that are subjected to repetitive use and friction.

- Ductility and Toughness: While high carbon steel is less ductile than low carbon steel, it still maintains a degree of toughness. The right heat treatment process can enhance the steel’s toughness, making it capable of absorbing energy and resisting impact. This balance of hardness and toughness is crucial for applications where both strength and resistance to fracture are needed.

- Elasticity and Modulus of Elasticity: High carbon steel exhibits good elasticity, which is the ability to return to its original shape after deformation. The modulus of elasticity, a measure of the material’s stiffness, is also relatively high in high carbon steel. These properties are essential for applications like springs and suspension components, where the material must withstand repeated loading and unloading cycles without permanent deformation.

- Thermal Conductivity: The thermal conductivity of high carbon steel is another important property, especially in applications involving heat transfer. High carbon steel can conduct heat efficiently, making it suitable for use in heat exchangers, radiators, and other thermal management systems.

- Corrosion Resistance: Although high carbon steel is not as corrosion-resistant as stainless steel, it can be treated to improve its resistance to rust and corrosion. Protective coatings, such as galvanization or the application of corrosion-resistant alloys, can enhance the durability of high carbon steel in corrosive environments.

Conclusion

High carbon steel’s mechanical properties make it a versatile and indispensable material in various industrial applications. At Virat Special Steels, we are committed to providing high-quality high carbon steel that meets the rigorous demands of our customers. Whether you need steel for cutting tools, machinery, or structural components, our high carbon steel offerings deliver the strength, hardness, and durability required for optimal performance.

Explore our range of high carbon steel products and discover how Virat Special Steels can meet your specific needs with precision and excellence. HCHCr. (DIN 2379, 2080 / AISI D2, D3)

Size Range in Forged / Rolled Bars:

Rounds: 13mm Dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

Choose Virat Special Steels for unparalleled quality and service. Experience the difference that cutting-edge infrastructure and top-notch materials make.

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775