Archives

now browsing by author

Virat Steels & NLMK Verona at Mach Auto Expo 2026 | European Tool Steel Excellence

Virat Steels & NLMK Verona at Mach Auto Expo 2026 | European Tool Steel Excellence

The countdown has begun for Mach Auto Expo 2026, India’s premier exhibition for industrial innovation, and this year promises something truly special. Virat Special Steels Pvt. Ltd., a trusted name in premium steel solutions, is proud to partner with NLMK Verona, Europe’s renowned tool steel manufacturer, to display the cutting-edge products and global expertise under one roof.

A Partnership Forged in Strength

Virat Special Steels Pvt. Ltd. has always been committed to delivering world-class steel solutions. By joining hands with NLMK Verona, we bring the best of European tool steel technology directly to Indian manufacturers. This collaboration ensures:

- Superior quality standards backed by European precision.

- Wide product range for automotive, engineering, and heavy machinery sectors.

- Global expertise with local support, combining NLMK’s innovation with Virat’s trusted service.

Why Visit us at Mach Auto Expo 2026?

At our booth, visitors will experience:

- Live product showcases of premium tool steels designed for durability and performance.

- Technical insights from experts on applications, machining, and heat treatment.

- Networking opportunities with industry leaders and decision-makers.

- Exclusive offers for expo attendees, reinforcing our commitment to customer success.

India’s manufacturing sector is evolving rapidly, and the demand for high-performance tool steel is greater than ever.

Join Us at Mach Auto Expo 2026

📍 Hall No. 1 | Booth No. B7 , LEC Ludhiana, Punjab

📅 Date: February 20th ,21st, 22nd,23rd 2026

Whether you are an OEM, supplier, or industry enthusiast, this is your chance to explore European tool steel excellence—right here in India.

Connect With Us Today –

📧 Email: info@viratsteels.com 🌐 Website: www.viratsteels.com 📞 Phone: +91-9814021775 ,9216321774 ,9216321778

Virat Steels & NLMK Verona – Building Strength, Shaping the Future.

Virat Special Steels -India’s Premium Tool Steel Stockiest

An Authorized Partner Of NLMK Verona, Italy

With 7 decades of experience in metal domain, Virat Special Steels is a trusted & successful pan-India supplier of tool and die steels backed by 3 regional stocking yards, 2,000+ tons of inventory, offering more than 35 specialized grades , advanced cutting facilities, ensuring fast and reliable deliveries, strengthened by a growing base of 1800+ satisfied customers across India, making us one of the Best reliable and preferred tool steel suppliers..

By combining European manufacturing excellence (the authorized stockist of NLMK Verona, Italy) with strong local service and technical expertise, the company enables Indian toolmakers to compete confidently on a global level now easily accessible with:

- consistent quality with premium metallurgical properties

- reliable supply, even during market shortages

- proven performance material in critical applications

- complete documentation and traceability

India’s Largest Steel Stock Availability –

For the first time in India, we offer extra-large steel blocks up to 1300mm x 3000mm x 6000mm ensuring that industries requiring precision steel, heavy-duty moulds, and large-scale production can rely on us for consistent supply and superior quality.

We provide a wide range of premium steel grades to meet diverse industrial needs ensuring availability even during periods of market volatility and steel shortages.

- Hot Work Steel: DB6, H-13, H-11

- High-Speed Steel: M2, M35, T1

- Cold Work Steel: D2, D3

- Plastic Mould Steel: P20, P20+Ni

Whether you are in automotive, manufacturing, tooling, or mould-making, our steel solutions are designed to deliver performance, durability, and efficiency.

Looking Ahead –

Our reputation as a leading steel importer, exporter, and stockist in India is built on reliability, trust and global partnerships.

Meet Us at Mach Auto Expo – Steel Solutions for Every Industry

Join us at the Mach Auto Expo to explore our premium steel offerings: 📍 Hall No. 1 | Booth No. B7

Explore how Virat Special Steels can empower your projects with world-class steel solutions.

Connect With Us Today –

📧 Email: info@viratsteels.com 🌐 Website: www.viratsteels.com 📞 Phone: +91-9814021775

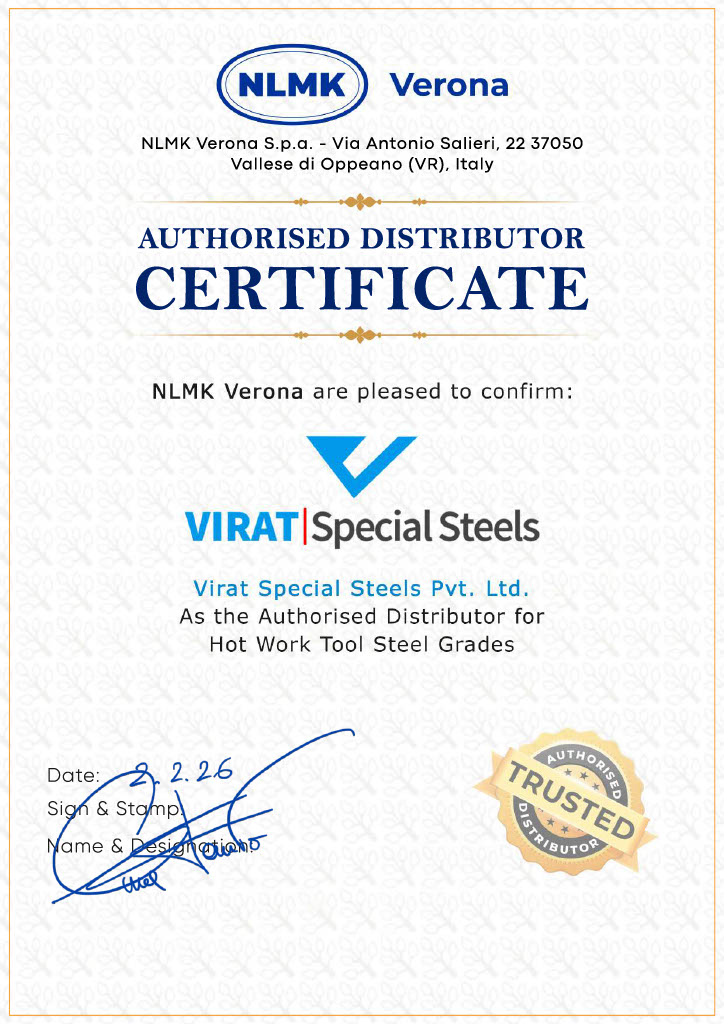

Virat Special Steels Recognized as Authorised Distributor by NLMK Verona

[Strengthening India’s Access to Genuine European Tool Steel]

Virat Special Steels Pvt. Ltd. is proud to announce a significant milestone in our journey—official recognition as the Authorised Distributor for Hot Work Tool Steel Grades by NLMK Verona S.p.a., Italy. This milestone, dated 2nd February 2026, marks a new chapter in our commitment to delivering excellence in the steel industry.

Virat Special Steels Pvt. Ltd. has been recognized as one of the largest Importers, Exporters, and Stockists of premium steel products of :

- Die Blocks (DIN 1.2714, DB6, H13, H11)

- Tool Steels & Die Steels

- Special Steels & Alloy Steels in multiple grades

Backed by decades of expertise, the company maintains the largest steel yards, ensuring consistent availability, unmatched quality, and timely delivery to domestic industries.

NLMK Verona, a renowned name in the global steel sector, has entrusted Virat Special Steels with the responsibility of distributing their Hot Work Tool Steel Grades in India. This partnership reflects not only our technical expertise but also the trust we have built over the years with our customers and partners.

What This Means for Our Customers

Being an Authorised & Trusted Distributor ensures that our customers benefit from:

- Authentic NLMK Verona products with guaranteed quality

- Reliable supply chain solutions met to industry needs

- Global standards of excellence delivered locally

- On-ground technical support and grade selection support

Whether you are manufacturing dies, Molds, or critical tooling components, Virat Steels ensures your tools are built on proven European steel excellence drive productivity.

Looking Ahead

This achievement is not just a certificate— It’s a promise of authentic material, consistent quality, and strong technical partnership for the Indian tooling industry.

European tool steel excellence is now officially within reach.

Connect with Virat Special Steels to explore NLMK Verona’s authorised tool and die steel range and elevate your tooling performance.

Web: www.viratsteels.com

Email Us: info@viratsteels.com.

Ph: 98140-21775, 9999124971-80 , 9216321771-79.

NLMK Verona Tool Steel: Tough & Stable

When it comes to tool steel suppliers in India, industries demand materials of high strength, precision, and durability. Virat Steels having great experience consistently in metal domain for 7 decades bringing you the finest in European engineering—NLMK Verona Tool Steel. Known worldwide for its toughness, stability, and performance, this steel is trusted across sectors where reliability is non-negotiable.

What Makes NLMK Verona Tool Steel Exceptional?

NLMK Verona, part of the globally respected NLMK Group, is a leader in European tool steel manufacturing. Their products are engineered to hold extreme industrial conditions, ensuring longer service life and superior efficiency.

- Unmatched Toughness

- Dimensional Stability

- High Performance

Optimized for demanding applications like die-making, forging, and cutting tools.

Applications Across Industries

NLMK Verona’s tool steels are trusted in sectors where precision and durability are non-negotiable:

- Automotive Manufacturing: For molds, dies, and wear-resistant components.

- Aerospace Engineering: Ensuring stability in parts exposed to extreme conditions.

- Heavy Engineering: Industrial machinery, specialized tools.

- General Manufacturing: From injection Molds to stamping dies, performance is guaranteed.

Virat Steels: Your Trusted Tool Steel Supplier in India

Virat Steels don’t just supply steel—We deliver solutions engineered for success. By offering NLMK Verona European Tool Steel, we empower our clients with materials that defines with excellent cutting-edge metallurgy technology.

When you choose Virat Steels, you are choosing:

- Global quality with local expertise

- Quick Service

- Technical guidance to your needs

NLMK Verona’s European Tool Steel is more than just a material—it’s truly a commitment to performance. At Virat Steels, we are proud to bring this world-class steel to industries across India, ensuring that our customers stay ahead in quality and productivity.

Looking for the best tool steel suppliers in India?

Choose Virat Steels—your gateway to Italian Tool steel excellence & Discover authentic European quality with full assurance.

Meanwhile for more details explore on- https://www.viratsteels.com/

Email Us: info@viratsteels.com.

Ph: 98140 – 21775, 99991 – 24971 to 80 , 92163-21771 to 79.

Global Quality With NLMK . Local Reliability With Virat Steels.

In today’s competitive manufacturing sector, material quality is truly a important parameter. For toolmakers, die manufacturers, and OEM suppliers, the difference between consistent output and recurring failure often begins with the quality of tool steel.

For decades, European tool and die steels have been set global benchmarks for their performance, reliability, and longevity. Today, that same European steel excellence is no longer distant or difficult to access—it is now locally available in Virat Steels – India, backed by trusted partnerships and reliable supply chains.

European Tool Steel: A Proven Benchmark –

European tool steel manufacturers—particularly NLMK Verona—are globally recognized for their strict quality control, advanced refining processes, and consistent heat-treatment performance.

These superior metallurgical standards deliver:

- longer die and mould life

- Excellent toughness and hardness balance

- Superior surface finish after machining

- Lower rejection rate

The result is predictable performance, higher productivity, and long-term cost efficiency for demanding tooling applications.

Now Local Availability with Trusted Indian Support –

With 70+ years of experience in metal domain, Virat Steels is a trusted & successful pan-India supplier of tool and die steels backed by 3 regional stocking yards, 3,500+ tons of inventory, and advanced cutting facilities, ensuring fast and reliable deliveries.

The company remains committed to delivering premium grades such as: DIN 1.2714 | 1.2344 | 1.2738 | 1.2379 | HSS M2, M35 , T1 and more ensuring availability even during periods of market volatility and steel shortages.

By combining European manufacturing excellence with strong local service and technical expertise, Virat Steels enables Indian toolmakers to compete confidently on a global level now easily accessible with:

- consistent quality with premium metallurgical properties

- reliable supply, even during market shortages

- proven performance material in critical applications

- complete documentation and traceability

If you are looking to upgrade your tooling materials and align with global level, now is the time to experience European tool steel—locally supported, reliably supplied, and technically assured by Virat Steels.

Please Consult our office for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Ph: 98140 – 21775, 99991 – 24971 to 80 , 92163-21771 to 79.

European Die Steels for Longer Tool Life – Backed by NLMK Verona (Italy) & Virat Steels (India)

When it comes to tool and die steel, what it truly matters is –tool life, that truly considered as an important technical parameter for improved productivity. This is where European Tool & Die Steel continues to stand out as a proven solution.

Why European Tool Steel Stands Apart?

Globally, European tool steels are recognized for :

- Their advanced steel making technology,

- Strict quality control,

- Consistent performance.

NLMK Verona – European Excellence from Italy

NLMK Verona, based in Verona, Italy—an industrial hub known for metallurgical excellence—is a reputed European producer of high-performance tool and die steels engineered for:

- More tougher & crack-resistant

- Easier to machine

- More dimensionally stable.

When combined with a trusted Indian supply partner, they deliver excellence across tooling and die-making applications in India.

Bringing European Tool Steel to India: NLMK Verona × Virat Steels

Through partnership of NLMK Verona with Virat Steels, now Indian industries will have easier access to European-grade steel with reliable local stocking and service & technically supported solutions.

With over 70+ years of experience in the Indian metal industry, Virat Steels remains a trusted partner for toolmakers and manufacturers, supplying premium grades such as:

DIN 1.2714 | 1.2344 | 1.2738 | 1.2379 | HSS M2, M35 , T1 and more backed by the strong manufacturing expertise of NLMK Verona.

Looking for Genuine European Tool Steel with Assured Performance?

Manufacturers, toolmakers, and industry professionals are invited to connect with us at Mach Auto Expo 2026 to explore more premium European Tool & Die Steel solutions.

📍 Venue: LEC, Ludhiana (Punjab)

📅 Date: 20th Feb -23rdFeb 2026

Visit us to discuss tooling challenges, explore NLMK Verona steel grades, and understand how the right material choice can deliver longer tool life and consistent performance.

From Quality Crisis to Quality Assurance: Virat–NLMK Is Bringing Imported Tool Steel in India

Virat–NLMK Imported Tool Steel in India | Quality Assurance & European Grades.

A Turning Point for India’s Tool Steel Industry

India’s tool and die steel industry is under pressure from rising costs, inconsistent quality, supply disruptions & manipulating “European material” claims. Despite strong demand, access to genuinely high-quality tool steel remains limited leading to growing quality crisis that impacting on productivity and damaging the trust between suppliers and end users across manufacturing sectors.

Genuine European Tool Steel makes the difference –

True European tool steels are manufactured under metallurgical control and advanced refining processes deliver:

• More Dimensionally stable

• Great mechanical properties

• Extended tool life & Higher productivity

Now Available in India Through Virat Steels –

Virat Special Steels , India a trusted name in India’s tool and die steel industry with over 70 years of experience, is proud to announce its partnership with NLMK Verona, Italy-one of Europe’s most reputed makers of high-performance tool and die steels-bringing premium European tool steel to the Indian market.

Until now, only selected suppliers in India are able to offer imported European tool and die steel grades to manufacturers. At a time when the domestic steel industry is facing volatility, Virat Steels, India has built a strong collaboration with NLMK Europe, ensuring reliable local availability and bringing quality to the shop floor.

NLMK Verona’s European metallurgical excellence with Virat Special Steels’ strong Indian stocking, logistics, and technical support, reduce the gap between global quality and local availability.

Global Steel Excellence, Now within Reach

Premium European tool steel is no longer out of reach.

The future of tool steel in India has arrived. Through Virat Special Steels, It is now locally available, reliable, and ready to support the next level of Indian manufacturing.

Looking for genuine European tool steel with assured performance?

👉 Connect with Virat Special Steels to explore NLMK Verona’s premium tool and die steel grades and experience genuine quality assurance.

Meet Us at Mach Auto Expo, Ludhiana on Feb 2026

We invite you to connect with us to explore premium imported materials and industry-focused solutions that will help keep your business ahead — even in challenging times from Leading Indian Supplier Virat Steels.

Venue: Mach Auto Expo 2026, LEC , Ludhiana (Punjab)

Quality Crisis in Tool Steels-Why Reliability matters today?

The domestic steel sector is passing through one of its most challenging phases in recent times. Rising raw material costs, uneven quality, supply chain disruptions, and intense price competition have put immense pressure on both the manufacturers and end users. Even a few established German companies also have sold out or shut down their mills and facilities.

While demand from forging, automotive, plastics, and heavy engineering sectors continues, it is becoming more difficult to find die steel and truly high quality tools.

A Growing Industrial Risk

Unfortunately, today many buyers are being misled in the name of “European material”. The major concern is the manipulation of materials by certain suppliers. They charge premium prices while supplying sub-standard materials under the label of premium brands.

What actually happens- is that such suppliers focus only on short-term gains instead of true quality & they may win orders temporarily, but in doing so they break the trust between genuine steel suppliers and end users and ultimately damage the reputation of the image of genuine suppliers who truly deliver certified, high-quality steel.

Industry Challenges: When Solutions Matter the Most

Across industrial sectors, manufacturers are experiencing

- Fluctuating domestic quality

- Shorter tool life

- Premature cracking and

- Increasing expectations for precision and performance.

These issues directly impact productivity, machining accuracy, and overall tool life. In such a scenario, access to reliability, quality, the world-class steel becomes truly essential.

What industries need today is consistent, high-grade steel that meets global standards — not just in name, but in actual performance. This is where European steel material makes a clear difference, enabling higher productivity and long-term growth.

European Tool Steel: Now Closer to Indian Manufacturers

Until now, Only selected suppliers in India have truly been able to offer imported European tool and die steel grades to manufacturers. Over 70 years’ experience in metal domain , Virat Special Steels, India is changing this scenario by making these Premium European Steels more accessible to the Indian industry through strong local stocking, quick service, and technical support guidance with seamless performance and precision right on their shop floor.

Premium European tool steel is no longer out of reach — it is now locally available, reliable and ready to support the Indian manufacturing through Virat Special Steels.

Why is H13 Steel Ideal for Hot Work Tool Applications?

H13 steel is one of the most widely used hot work tool steels, known for its exceptional performance in high-temperature environments. Classified as an air-hardening chromium-molybdenum-vanadium steel, H13 offers an excellent combination of heat resistance, toughness, and wear resistance.

Tool steels like H13 are crucial in industries that require durable and long-lasting tools, such as die casting, forging, and extrusion. Their ability to withstand extreme temperatures without losing mechanical integrity makes them the preferred choice for demanding applications.

What Are Hot Work Tool Applications?

Hot work tool applications involve operations where tools are exposed to high temperatures, mechanical stresses, and rapid cooling cycles. These conditions demand materials that can maintain their properties without deformation, cracking, or excessive wear.

Industries Using Hot Work Tools

Several industries rely on hot work tools, including:

- Die casting – for producing metal components with intricate shapes

- Forging – shaping metals under extreme pressure

- Extrusion – forming materials into continuous profiles

- Plastic molding – high-heat plastic injection processes

Challenges in Hot Work Environments

Hot work tools face significant challenges, such as:

- High-temperature exposure leading to softening

- Thermal fatigue causing cracks

- Abrasive wear from repeated contact with molten metals

- Mechanical stress-induced failure

This is where H13 steel shines, offering unparalleled resistance to these harsh conditions.

Key Properties of H13 Steel

High Heat Resistance

H13 steel can endure temperatures up to 600°C (1112°F) without losing hardness. This makes it ideal for tools that come into direct contact with molten metals and other high-temperature environments.

Excellent Toughness and Ductility

Toughness is a critical factor in preventing cracking and chipping in hot work tools. H13’s balanced alloy composition provides excellent impact resistance, ensuring tools can withstand mechanical shocks and stress without failure.

Superior Wear Resistance

H13 offers outstanding wear resistance due to its alloying elements, particularly chromium and vanadium. This helps tools maintain their shape and performance over extended periods, reducing downtime and replacement costs.

Good Thermal Conductivity

Efficient heat dissipation is crucial in preventing overheating and thermal fatigue. H13 steel’s thermal conductivity allows it to distribute heat evenly, reducing localized stress and extending tool life.

High Hardenability and Stability

H13 retains its mechanical properties even after repeated heating and cooling cycles. It undergoes heat treatment effectively, ensuring a consistent hardness level and making it easier to machine.

Applications of H13 Steel in Hot Work Tools

Die Casting Molds

Die casting molds require materials that can withstand molten metal injections at high speeds and pressures. H13 steel’s resistance to heat checking and wear makes it ideal for casting aluminum, zinc, and magnesium.

Forging Dies

H13 is widely used in hammer and press forging dies, where it must endure extreme pressure and temperature fluctuations. Its ability to resist thermal fatigue helps prevent premature failure.

Extrusion Dies

Metal extrusion processes generate intense heat and stress. H13 steel ensures dimensional accuracy and prolonged die life, making it the go-to choice for aluminum and steel extrusion dies.

Plastic Molding Dies

In plastic injection molding, molds are subjected to repeated heating and cooling. H13’s stability ensures it can handle continuous cycles without deforming, making it perfect for high-volume production.

Comparing H13 Steel with Other Tool Steels

| Property | H13 Steel | D2 Steel | A2 Steel | P20 Steel |

| Heat Resistance | High | Medium | Low | Medium |

| Wear Resistance | High | Very High | Medium | Low |

| Toughness | High | Low | High | Medium |

| Thermal Conductivity | High | Low | Medium | High |

| Applications | Hot work | Cold work | General-purpose | Plastic molds |

H13 stands out as the best choice for hot work applications, offering a balance of wear resistance, toughness, and heat resistance.

Conclusion

H13 steel is a top-tier material for hot work tool applications, thanks to its:

- Exceptional heat resistance for high-temperature environments

- Toughness and durability to withstand mechanical stress

- Superior wear resistance for prolonged tool life

- Thermal stability to prevent overheating and deformation

With its outstanding properties, H13 remains the preferred steel for industries requiring high-performance hot work tools.

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

FAQs

- What makes H13 better than other tool steels for hot work applications?

- H13 offers a superior combination of heat resistance, toughness, and wear resistance, making it ideal for demanding applications.

- Can H13 steel be used for cold work applications?

- While possible, H13 is specifically designed for hot work applications and may not perform as well in cold work environments.

- What is the typical hardness range of H13 steel after heat treatment?

- After proper heat treatment, H13 steel can achieve a hardness of 48-52 HRC.

- How does H13 resist thermal fatigue in die casting?

- H13’s heat resistance and thermal conductivity prevent cracking and deformation in extreme temperatures.

- What industries benefit the most from H13 steel?

Die casting, forging, extrusion, and plastic molding industries rely on H13 for durable tooling solutions.

What is H13 Steel and Its Applications?

Introduction

When it comes to materials that can withstand extreme conditions, H13 steel stands out as a top contender. This versatile chromium-molybdenum hot work tool steel is renowned for its exceptional combination of toughness, hardness, and resistance to thermal fatigue. Its unique properties make it indispensable across various industries, from automotive to aerospace.

Chemical Composition of H13 Steel

The remarkable characteristics of H13 steel are rooted in its specific chemical makeup. The typical composition includes:

- Carbon (C): 0.32 – 0.40%

- Chromium (Cr): 5.13 – 5.25%

- Molybdenum (Mo): 1.33 – 1.4%

- Vanadium (V): 1.0%

- Silicon (Si): 1.0%

- Manganese (Mn): 0.20 – 0.50%

Each element plays a pivotal role:

- Carbon enhances hardness and strength.

- Chromium improves hardenability and resistance to oxidation.

- Molybdenum increases toughness and high-temperature strength.

- Vanadium contributes to wear resistance and grain refinement.

- Silicon boosts strength and elasticity.

- Manganese aids in deoxidation during steel production.

This balanced composition ensures that H13 steel maintains its integrity under demanding conditions.

Physical Properties of H13 Steel

Understanding the physical properties of H13 steel provides insight into its performance in various applications:

- Density: Approximately 7.80 g/cm³ (0.282 lb/in³)

- Thermal Conductivity: 24.3 W/m-K at 215°C (419°F)

- Coefficient of Thermal Expansion: 11.0 µm/m-°C between 25°C and 95°C

These properties indicate that H13 steel can efficiently conduct heat while maintaining dimensional stability, crucial for tools exposed to rapid temperature changes.

Mechanical Properties of H13 Steel

The mechanical prowess of H13 steel is evident in its ability to withstand substantial stress without deformation:

- Hardness: Rockwell C scale hardness ranges from 28 to 53, depending on heat treatment.

- Tensile Strength: Ultimate tensile strength can reach up to 1990 MPa (289,000 psi).

- Toughness: Demonstrates excellent toughness, essential for resisting cracking under impact.

These attributes make H13 steel suitable for applications requiring both strength and durability.

Heat Treatment Processes for H13 Steel

To optimize its properties, H13 steel undergoes specific heat treatment processes:

- Annealing: Heating to 1550°-1650°F, holding until uniformly heated, then cooling slowly to about 1000°F to soften the steel for machining.

- Hardening: Heating to 1800°-1850°F, followed by air or oil quenching to achieve desired hardness.

- Tempering: Reheating to 1000°-1150°F, depending on the required hardness, to reduce brittleness.

These treatments enhance the steel’s performance in various applications.

Advantages of Using H13 Steel

H13 steel offers several notable benefits:

- High-Temperature Resistance: Maintains strength and hardness at elevated temperatures, making it ideal for hot work applications.

- Wear Resistance: The presence of vanadium carbides provides excellent resistance to abrasion.

- Thermal Fatigue Resistance: Can withstand repeated heating and cooling cycles without cracking.

These advantages contribute to its widespread use in demanding environments.

Applications

1. Applications in Hot Work Tooling

H13 steel is widely used in hot work tooling applications where materials are subjected to high temperatures and extreme mechanical stress. Some of its key applications in this domain include:

- Die Casting Dies: H13 steel is commonly used for die-casting dies due to its excellent heat resistance, wear resistance, and toughness. The ability to withstand the rapid heating and cooling cycles involved in die-casting operations ensures longer tool life.

- Extrusion Dies: In aluminum and other metal extrusion processes, H13 steel is used to manufacture dies that shape and form metal billets. The steel’s strength and thermal stability prevent premature wear and deformation.

- Forging Dies: H13 steel is used in the production of forging dies that shape metal parts through high-pressure impacts. The toughness and heat resistance of H13 help the dies maintain their shape under extreme conditions.

These applications make H13 an indispensable material in the hot work tooling industry, ensuring efficiency, precision, and durability.

2. Applications in Cold Work Tooling

Although primarily known for hot work applications, H13 steel also finds limited usage in cold work tooling where wear resistance and impact strength are required. Some examples include:

- Shear Blades: H13 steel is used for manufacturing shear blades that cut or trim metal sheets, where its hardness and durability contribute to precision and long service life.

- Stamping Dies: H13 is occasionally used in stamping dies for cold-forming applications, where its wear resistance helps maintain die integrity.

- Plastic Molds: While more common in hot work environments, H13 is also used for plastic injection molding where high strength and heat resistance are necessary.

Although other cold work steels like D2 or O1 may be preferred for most cold work applications, H13’s versatility allows it to be used where both wear resistance and toughness are required.

3. Use in Plastic Injection Molding

H13 steel is one of the top choices for plastic injection molding tools, particularly for mold inserts. Some advantages include:

- High Thermal Conductivity: Ensures efficient heat dissipation, reducing cycle times and improving productivity.

- Wear and Corrosion Resistance: Prevents mold degradation, ensuring longevity and consistent production quality.

- Dimensional Stability: H13 maintains its structure under high pressure and temperature, reducing warping and defects in molded parts.

These properties make H13 a preferred material for injection molding applications, where durability and precision are critical.

4. H13 Steel in the Automotive Industry

The automotive sector relies on H13 steel for various high-performance applications. Some of the most common uses include:

- Engine Components: H13 steel is used in manufacturing engine components such as cylinder heads, pistons, and exhaust valves, where high-temperature resistance is necessary.

- Structural Parts: Some automotive manufacturers use H13 in critical structural components that must withstand mechanical and thermal stress.

- Tooling for Manufacturing: Many of the dies and molds used in automotive production, including stamping dies and injection molds, are made from H13 steel.

The exceptional properties of H13 steel help improve the durability and performance of automotive parts and manufacturing processes.

5. H13 Steel in the Aerospace Industry

The aerospace industry demands materials with superior strength, heat resistance, and toughness. H13 steel meets these requirements and is used in:

- Turbine Blades: Due to its heat resistance, H13 is used in manufacturing certain aerospace turbine components exposed to high temperatures.

- Structural Components: Some aerospace structures, including landing gear and support brackets, benefit from the toughness of H13 steel.

With the aerospace industry constantly pushing for high-performance materials, H13 remains a strong candidate for demanding applications.

Conclusion

H13 steel is a versatile and high-performance material used in numerous industries, including automotive, aerospace, die-casting, and injection molding. Its unique combination of high-temperature resistance, wear resistance, and toughness makes it an ideal choice for hot work tooling and other demanding applications. While it has some limitations, proper heat treatment and machining techniques help maximize its benefits. Whether in the production of industrial tools, aerospace components, or plastic molds, H13 remains a top-tier tool steel for high-performance applications.

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

FAQs

1. What makes H13 steel suitable for high-temperature applications?

H13 steel has excellent thermal fatigue resistance, high wear resistance, and superior toughness, making it ideal for high-temperature applications such as die casting and forging.

2. How does H13 steel compare to D2 tool steel?

H13 is better suited for high-temperature applications, while D2 is a cold work steel with superior wear resistance. Choosing between them depends on whether heat resistance or abrasion resistance is a priority.

3. Can H13 steel be welded?

Yes, H13 steel can be welded, but it requires preheating and post-weld heat treatment to prevent cracking and ensure structural integrity.

4. What industries commonly use H13 steel?

H13 steel is widely used in die-casting, plastic injection molding, aerospace, automotive manufacturing, and hot work tooling applications.

5. How does heat treatment affect H13 steel?

Proper heat treatment enhances H13 steel’s hardness, strength, and resistance to thermal fatigue, ensuring optimal performance in demanding applications.