Die Steel H13

now browsing by category

Why is H13 Steel Ideal for Hot Work Tool Applications?

H13 steel is one of the most widely used hot work tool steels, known for its exceptional performance in high-temperature environments. Classified as an air-hardening chromium-molybdenum-vanadium steel, H13 offers an excellent combination of heat resistance, toughness, and wear resistance.

Tool steels like H13 are crucial in industries that require durable and long-lasting tools, such as die casting, forging, and extrusion. Their ability to withstand extreme temperatures without losing mechanical integrity makes them the preferred choice for demanding applications.

What Are Hot Work Tool Applications?

Hot work tool applications involve operations where tools are exposed to high temperatures, mechanical stresses, and rapid cooling cycles. These conditions demand materials that can maintain their properties without deformation, cracking, or excessive wear.

Industries Using Hot Work Tools

Several industries rely on hot work tools, including:

- Die casting – for producing metal components with intricate shapes

- Forging – shaping metals under extreme pressure

- Extrusion – forming materials into continuous profiles

- Plastic molding – high-heat plastic injection processes

Challenges in Hot Work Environments

Hot work tools face significant challenges, such as:

- High-temperature exposure leading to softening

- Thermal fatigue causing cracks

- Abrasive wear from repeated contact with molten metals

- Mechanical stress-induced failure

This is where H13 steel shines, offering unparalleled resistance to these harsh conditions.

Key Properties of H13 Steel

High Heat Resistance

H13 steel can endure temperatures up to 600°C (1112°F) without losing hardness. This makes it ideal for tools that come into direct contact with molten metals and other high-temperature environments.

Excellent Toughness and Ductility

Toughness is a critical factor in preventing cracking and chipping in hot work tools. H13’s balanced alloy composition provides excellent impact resistance, ensuring tools can withstand mechanical shocks and stress without failure.

Superior Wear Resistance

H13 offers outstanding wear resistance due to its alloying elements, particularly chromium and vanadium. This helps tools maintain their shape and performance over extended periods, reducing downtime and replacement costs.

Good Thermal Conductivity

Efficient heat dissipation is crucial in preventing overheating and thermal fatigue. H13 steel’s thermal conductivity allows it to distribute heat evenly, reducing localized stress and extending tool life.

High Hardenability and Stability

H13 retains its mechanical properties even after repeated heating and cooling cycles. It undergoes heat treatment effectively, ensuring a consistent hardness level and making it easier to machine.

Applications of H13 Steel in Hot Work Tools

Die Casting Molds

Die casting molds require materials that can withstand molten metal injections at high speeds and pressures. H13 steel’s resistance to heat checking and wear makes it ideal for casting aluminum, zinc, and magnesium.

Forging Dies

H13 is widely used in hammer and press forging dies, where it must endure extreme pressure and temperature fluctuations. Its ability to resist thermal fatigue helps prevent premature failure.

Extrusion Dies

Metal extrusion processes generate intense heat and stress. H13 steel ensures dimensional accuracy and prolonged die life, making it the go-to choice for aluminum and steel extrusion dies.

Plastic Molding Dies

In plastic injection molding, molds are subjected to repeated heating and cooling. H13’s stability ensures it can handle continuous cycles without deforming, making it perfect for high-volume production.

Comparing H13 Steel with Other Tool Steels

| Property | H13 Steel | D2 Steel | A2 Steel | P20 Steel |

| Heat Resistance | High | Medium | Low | Medium |

| Wear Resistance | High | Very High | Medium | Low |

| Toughness | High | Low | High | Medium |

| Thermal Conductivity | High | Low | Medium | High |

| Applications | Hot work | Cold work | General-purpose | Plastic molds |

H13 stands out as the best choice for hot work applications, offering a balance of wear resistance, toughness, and heat resistance.

Conclusion

H13 steel is a top-tier material for hot work tool applications, thanks to its:

- Exceptional heat resistance for high-temperature environments

- Toughness and durability to withstand mechanical stress

- Superior wear resistance for prolonged tool life

- Thermal stability to prevent overheating and deformation

With its outstanding properties, H13 remains the preferred steel for industries requiring high-performance hot work tools.

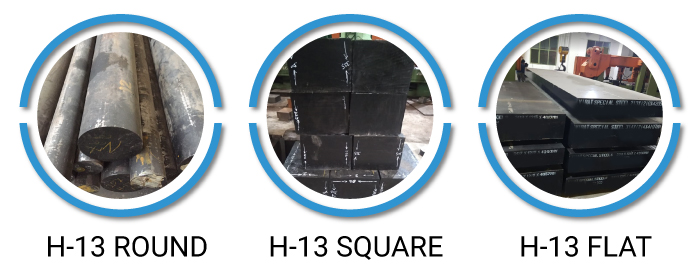

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

FAQs

- What makes H13 better than other tool steels for hot work applications?

- H13 offers a superior combination of heat resistance, toughness, and wear resistance, making it ideal for demanding applications.

- Can H13 steel be used for cold work applications?

- While possible, H13 is specifically designed for hot work applications and may not perform as well in cold work environments.

- What is the typical hardness range of H13 steel after heat treatment?

- After proper heat treatment, H13 steel can achieve a hardness of 48-52 HRC.

- How does H13 resist thermal fatigue in die casting?

- H13’s heat resistance and thermal conductivity prevent cracking and deformation in extreme temperatures.

- What industries benefit the most from H13 steel?

Die casting, forging, extrusion, and plastic molding industries rely on H13 for durable tooling solutions.

H13 Tool Steel Hardness: Methods to Test and Optimize Performance

Introduction

H13 tool steel stands out for its remarkable durability and thermal resistance, making it a preferred choice in industries such as automotive, aerospace, and manufacturing. However, its effectiveness hinges on maintaining optimal hardness, which directly impacts wear resistance, toughness, and performance under stress. This article explores various methods for testing H13 steel hardness and strategies to optimize it for maximum utility.

What is H13 Tool Steel?

H13 is a chromium-molybdenum hot work tool steel renowned for its exceptional strength and heat resistance. It contains:

- Chromium for enhanced corrosion resistance.

- Molybdenum and vanadium for superior toughness and wear resistance.

H13’s properties make it ideal for applications like:

- Forging dies.

- Injection molding tools.

- Extrusion dies.

- Die-casting components.

This robust tool steel withstands thermal fatigue, making it invaluable in environments with rapid temperature fluctuations.

Read More >H13 Steel: A Comprehensive Guide by Virat Special Steels

Overview of H13 Steel

H13 Steel is a versatile hot-work tool steel highly regarded for its durability, resistance to thermal fatigue, and exceptional strength under high temperatures. This steel type plays a vital role in various industries, from manufacturing heavy-duty dies to precision machining applications. Thanks to its unique properties, H13 Steel stands as one of the most trusted materials in both high-stress and high-temperature environments.

Significance of H13 Steel in Various Industries

Whether it’s the aerospace sector, die-making, or automotive components manufacturing, H13 Steel provides the reliability and resilience these industries demand. Virat Special Steels supplies this high-grade steel in various formats, catering to diverse business requirements. Its availability in sheets, plates, and round bars ensures clients get tailor-made solutions.

Key Features of H13 Steel

What Makes H13 Steel Unique?

H13 Steel is characterized by its:

- Exceptional heat resistance.

- High toughness and tensile strength.

- Prolonged tool life due to abrasion resistance.

These features make it ideal for forging, die-casting molds, and extrusion dies, giving manufacturers a reliable solution for high-temperature applications.

Applications of H13 Steel in the Manufacturing Sector

Industries trust H13 Steel for critical operations such as:

- Die-casting: Durable under extreme heat, making it perfect for molds.

- Automotive Tools: Precision parts for gears and shafts.

- Forging Dies: Heat-resistance for consistent long-term usage.

H13 Steel Chemical Composition and Mechanical Properties

H13 Steel Chemical Composition

The chemical composition of H13 Steel includes key elements:

| Element | Percentage |

| Carbon (C) | 0.32-0.45% |

| Chromium (Cr) | 4.75-5.50% |

| Molybdenum (Mo) | 1.10-1.75% |

| Vanadium (V) | 0.80-1.20% |

| Silicon (Si) | 0.80-1.20% |

These elements contribute to its superior heat resistance and strength.

H13 Steel Mechanical Properties

Key mechanical features of H13 Steel are:

- Hardness (HRC): 48-54.

- Tensile Strength: 2800 MPa.

- Good machinability and polishability.

H13 Steel Types and Availability

H13 Steel Plates and Sheets

Virat Special Steels offers H13 Steel plates and sheets that cater to different industrial needs, including mold manufacturing and heavy equipment production. These materials can endure extreme conditions while retaining structural integrity.

H-13 Steel Round Bar

The H-13 Steel Round Bar is a popular format used for precision machining and heavy-duty applications. Virat Special Steels ensures superior surface finish and precise dimensions in their round bars.

H-13 Steel Square and Flat Bars

Flat bars and square bars are sought-after for crafting large molds and cutting tools. Their customizable dimensions provide tailored solutions to complex engineering requirements.

H13 Steel Equivalent Grades

Exploring H13 Steel Equivalent Grades Globally

H13 Steel has global equivalents that meet different industry standards:

- AISI H13 (USA): Widely recognized in North America.

- X40CrMoV5-1 (Europe): An equivalent under European norms.

- SKD61 (Japan): Known for precise tooling applications.

Understanding these grades helps international businesses ensure consistent material quality.

H13 Steel Manufacturers and Dealers

Top H13 Steel Manufacturers in the Industry

Virat Special Steels collaborates with industry-leading manufacturers to source premium-quality H13 Steel. Their close relationships ensure superior product quality at competitive prices.

Role of H13 Steel Dealers, Distributors, and Stockists

Distributors like Virat Special Steels play a crucial role in ensuring seamless availability across industries. Their inventory spans a broad range of sheets, plates, and bars, meeting high-demand timelines.

Conclusion

H13 Steel remains an invaluable asset in modern manufacturing. From its exceptional thermal resistance to durability under stress, it equips industries with materials that stand the test of time. Choosing reliable suppliers like Virat Special Steels ensures access to top-tier products that match exact business needs.

FAQs

- What is the standard chemical composition of H13 Steel?

H13 Steel is composed of Carbon (0.32-0.45%), Chromium (4.75-5.50%), Molybdenum (1.10-1.75%), and Vanadium (0.80-1.20%). - How is H13 Steel used in die-making?

H13 Steel’s durability and heat resistance make it ideal for manufacturing extrusion and die-casting molds. - What are the benefits of choosing H-13 Steel Round Bars?

Round bars offer superior machinability, making them a top choice for crafting precision components. - Can I get H13 Steel customized for specific applications?

Yes, Virat Special Steels provides customized H13 Steel solutions to meet diverse industrial demands. - How to find trusted H13 Steel dealers near me?

Look for authorized distributors like Virat Special Steels for reliable products and timely delivery.

Locations: Based in Gurgaon (Haryana) & Ludhiana (Punjab), India.

Get in touch with us today to place your requirement!

For more information visit

https://www.viratsteels.com/h13.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Why H13 is the preferred choice?

The physical characteristics of H13 steel are derived from the distinct make and composition of it. The concentration and ratios of different components need to be ensured as required so that the desirable attributes are secured. Failing the same, the molding dies may never deliver as per standards.

Apart from maintaining specific composition, other processes are also adhered to like annealing and tempering of the steel. H13 steel is forged at 1079 degree centigrade while the minimum forging threshold prescribed for it is 898 degree centigrade. Annealing is done at 871 degree centigrade and tempering of it is performed in the thermal range of 538 – 649 degree centigrade. These processes ensure that high tensile strength and elasticity is generated through the micro arraying of the components in the most even manner.

In fact micro structure of H13 steel is directly responsible for the characteristics that make it the preferred choice as for making hot injection molding, Forging, Extrusion dies etc. The thermal resistance that it offers as regards temperature variation during the injection of material is much superior as compared to other tools and dies steels in the hot work steel category. Virat Special Steels is a pioneer in the manufacture of H13 steel based products including all kinds of dies and moulds and ensures the optimized value by maintaining strict standards.

High applicative value of H13:

With the molding and dies applications growing multifold in the manufacturing economy around the world, H13 has emerged as the top choice. Not only for the hot working but it is also being actively used as cold working steel for tools and moulds. However, it is its capacity to withstand the wear and thermal induced corrosion that 2344 steel has felt wider acceptance in the hot injection molding and tooling applications in manufacturing enterprises. It allows long term use with little maintenance while the finesse and polishing potential that is carries for the finished product is of high standard too. This directly impacts the cost of the final product to be sent in market and ensures economy in production.

Further the ability to offer custom H13 products/moulds can increase productivity for companies that are engaged in making specialized products. www.h13steel.in / Viratsteels.com is a specialty manufacturer of H13 steels and offers highly versatile customized products to Indian and international clients.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website www.h13steel.in / www.viratsteels.com

Any further queries feel free to contact us:

🌐www.viratsteels.com 📬 info@viratsteels.com 📲+91-98140 21775

Exploring H13 Tool Steel Properties, Applications and Machining!

In the world of industrial tooling, H13 tool steel stands out as a versatile and high-performance material, essential for applications requiring exceptional hardness, toughness, and resistance to thermal fatigue. At Virat Special Steels, we specialize in providing quality H13 steel and expert support to meet diverse industry needs, whether for die casting, molding, or forging applications. This blog explores the key properties, applications, and machinability of H13 tool steel, which make it a go-to solution for tooling requirements worldwide.

Understanding H13 Tool Steel

H13 tool steel is a chromium-molybdenum-vanadium alloy, specifically engineered for high-stress applications, particularly in environments with elevated temperatures. Known for its unique balance of hardness, toughness, and heat resistance, H13 is widely used in die casting and hot forging tools where it faces constant wear and thermal cycling.

Here are some of the notable properties of H13 steel that make it so valuable:

- Hot Work Capability: H13 is classified as hot work tool steel, designed to withstand high temperatures and repetitive heating and cooling cycles.

- Excellent Hardness: H13 tool steel hardness is in the range of 44-54 HRC, depending on heat treatment, which allows it to resist deformation under high-stress conditions.

- Good Toughness: H13 offers a high level of impact resistance, which is essential for tools that encounter high-pressure and high-speed operations.

- Enhanced Thermal Fatigue Resistance: The steel’s composition and structure allow it to withstand thermal cycling without cracking, which is ideal for die casting and extrusion dies.

Applications of H13 Tool Steel

Due to its ability to endure high temperatures and maintain structural integrity under stress, H13 steel is widely used across various industrial sectors.

Some of its primary applications include:

- Die Casting Dies: Its resistance to thermal fatigue and wear makes H13 ideal for molds used in die casting, where repeated exposure to molten metals demands a material that won’t degrade under high heat.

- Forging Dies: H13’s toughness and hardness are suited for hot forging, where tools must withstand high impact and compressive forces.

- Extrusion Tools: H13 is frequently used for tools involved in the extrusion of metals due to its durability and ability to withstand high-pressure environments.

- Plastic Molding Dies: In plastic molding, H13 is used for molds that need to withstand both high temperatures and pressures while producing intricate shapes.

Machining H13 Tool Steel: Tips and Techniques

Machining H13 tool steel requires specific considerations due to its hardness and toughness.

Here are some strategies that can help optimize machining processes with H13:

- Use of Carbide Tools: Given its hardness, H13 should ideally be machined with high-quality carbide cutting tools to ensure precision and reduce tool wear.

- Moderate Speeds and Feeds: For effective machining, it’s recommended to use moderate cutting speeds and feeds to prevent overheating and maintain tool integrity.

- Coolant Utilization: Applying a coolant during machining helps reduce heat build-up, especially in high-speed operations, which can protect both the tool and workpiece.

- Heat Treatment: To improve machinability, H13 is typically machined in its annealed state and then heat-treated to achieve the desired hardness for its end application.

Why Choose Virat Special Steels for H13 Tool Steel?

At Virat Special Steels, we are committed to providing top-quality H13 tool steel tailored to meet the demands of your applications. Our expertise in steel distribution, coupled with our focus on high standards and customer support, ensures that you receive only the best material, whether you need H13 die steel, mold steel, or hot work tool steel.

Our team of experts is here to help guide you through selecting the right material for your needs, offering insights on H13 material properties, mechanical properties, and recommendations for machining and heat treatment. Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website https://www.h13steel.in / https://www.viratsteels.com/h13.html

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📲 +91-98140 21775

Exploring the Versatility of Die Steel H13 in Aluminium Extrusion!

Aluminium extrusion is a dynamic process that transforms aluminium alloy into objects with a definitive cross-sectional profile for a wide range of uses. The adaptability and efficiency of this process are significantly enhanced by the use of Die Steel H13, a material that stands as a true pinnacle of durability and performance.

Die Steel H13: A Material for High-Demand Applications

Die Steel H13 is renowned for its robustness and ability to withstand extreme conditions, which makes it an ideal choice for several critical applications:

- Die Casting: For aluminum pressure die casting, H13 is highly recommended due to its exceptional performance under high working temperatures and pressure.

- Forging Dies: Its capacity to withstand rapid cooling and resist thermal fatigue makes it suitable for forging dies, where it endures the rigors of heat treatment.

- Plastic Moulds: H13’s high polishability is advantageous in plastic mold applications, where it aids in producing high-quality finishes.

Quality Assurance and Expertise

Virat Special Steels underscores the reliability of H13 steel by ensuring it undergoes comprehensive ultrasonic inspection, yielding 100% positive results as per Non-Destructive Testing (NDT) standards. This commitment to quality assures safety and dependability in every product.

With over five decades of experience, Virat Special Steels has established itself as a paragon of precision and timely service. Their extensive inventory and readiness to supply underscore their position as a trusted partner in the industry.

Choosing Virat Special Steels Pvt. Limited for Aluminium Extrusion Die Steel

Opting for Virat Special Steels Pvt. Limited, India, for your aluminium extrusion die steel needs translates to a partnership with a company that prioritizes quality, reliability, and customer satisfaction. Their expertise and commitment to maintaining a ready stock ensure that clients receive the materials they need without delay.

In conclusion, Die Steel H13’s remarkable properties and the expertise of Virat Special Steels Pvt. Limited coalesce to provide a seamless and efficient solution for aluminium extrusion processes, promising an output that meets the highest standards of excellence.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Exploring the robustness and versatility of H13 Tool Steel?

H13 tool steel, known for its robustness and versatility, is a hot-work tool steel with a hardness range of 460-500 BHN. This makes it an excellent choice for various industrial applications, including those that involve extreme temperatures and pressures.

The steel’s unique properties are due to its composition, which includes a blend of chromium, molybdenum, and vanadium. This combination not only provides the hardness needed for high-wear applications but also offers good resistance to thermal fatigue and shock. As a result, H13 tool steel is commonly used in the manufacturing of dies for drop forgings, aluminum and low-pressure die casting, and extrusion processes.

One of the key features of H13 tool steel is its ability to withstand rapid cooling from high temperatures without cracking, which is essential for many hot work applications. Additionally, its ability to maintain high hardness at elevated temperatures is a significant advantage for cold work tooling applications.

For specific applications that require pre-hardened steel, H13 is available in a pre-hardened state with a standard hardness of 460-500 BHN. This pre-hardening process enhances the steel’s machinability and reduces the time and cost associated with heat treatment.

Virat Special Steels, a prominent stockist and supplier, offers H13 tool steel in various forms, including flat, square, and round bars, catering to a wide range of industrial needs. With the capability to provide steel in all sizes, Virat Special Steels ensures that specific requirements for tooling applications are met with precision.

The applications of H13 tool steel extend beyond the traditional uses. It is also utilized for making ejector pins, apparatus holders, shrink fit chucks, and injection molds. Its adaptability makes it a preferred material for tools and dies that require high toughness and durability.

For those interested in learning more about the specific details of H13 tool steel, or in placing an order for their industrial needs, Virat Special Steels provides comprehensive information and services to assist customers in making informed decisions.

In conclusion, H13 tool steel stands out as a reliable material for high-performance tooling applications. Its combination of hardness, resistance to thermal fatigue, and versatility in both hot and cold work scenarios make it a valuable asset in the manufacturing industry. Whether for standard or specialized applications, H13 tool steel continues to be a top choice for professionals seeking quality and durability in their tooling materials.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website www.h13steel.in / https://www.viratsteels.com/h13.html , https://www.viratsteel.in/products/h13-steel-supplier-in-india/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

We Provide our Special Steels in All Cities in India:

- Agra, Alwar, Ambala, Anand, Bhiwadi, Dehradun,

- Ghaziabad, Haridwar, Rudrapur, Delhi, Faridabad,

- Kanpur, Noida, Gurgaon, Manesar, Kundali,Chandigarh,

- Waluj , Vadodara, Pimpri – Chinchwad, Rajkot, Jaipur,

- Ahmedabad, Pithampur, Surat, Amravati, Vadodara,

- Indore, Bhopal, Ranchi, Jamshedpur, Howrah,Kolkata,

- Pune, Thane, Nashik, Mumbai, Navi Mumbai, Nagpur,

- Ambattur, Bangalore, Belgaum, Chittoor, Dindigul,

- Hyderabad, Ernakulam, Chennai, Secunderabad,

- Visakhapatnam, Coimbatore, Mysore, Nellore, Kochi,

- Thiruvananthapuram, Trivandrum, Vijayawada, Guntur,

- Tirupati, Nazarathpet, Kakinada, Kurnool and many

Industry’s Guide to Selecting the Right Hot Work Tool Steel!

In the dynamic world of manufacturing, selecting the right materials is crucial for success. Hot work tool steels are a critical component in this process, especially for industries that shape metals under high temperatures. These steels are designed to withstand the rigorous conditions of cutting and molding heated metals, making them indispensable for manufacturers.

Virat Special Steels stands out as a beacon in the supply of hot work tool steels, such as DB6, H13, and H11. Their extensive inventory and expertise make them a go-to for industries in need of high-quality materials that can endure the heat, beat, and repeat cycle of manufacturing processes.

Understanding the unique properties of hot work tool steels like DB6, H13, H11, and H21 is essential. For instance, H13 is renowned for its exceptional heat resistance, toughness, and wear resistance, making it ideal for die casting dies and extrusion tools. These characteristics are vital for maintaining the integrity of tools and ensuring the consistency of manufactured products.

Virat Special Steels offers these materials in various forms, including flat, square, and round bars, catering to diverse manufacturing needs. Their mode of supply ensures that manufacturers have access to the right type of steel in the required shape, enhancing the efficiency of production lines.

For manufacturers looking to push the boundaries of what’s possible, partnering with knowledgeable suppliers like Virat Special Steels is a step towards achieving superior results. With the right hot work tool steel, the future of manufacturing looks bright, shaped by the principles of heat, beat, and repeat.

For detailed guidance and assistance in selecting the perfect hot work tool steel for your manufacturing needs, consulting with the experts at Virat Special Steels is highly recommended. Their team is equipped to handle queries and provide solutions that propel manufacturing operations to new heights.

Embrace the future of manufacturing with the right materials and expertise, and watch your operations transform with the power of hot work tool steel.

Contact us today to learn more!

https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Know more about H13 Tool Steel Supplier in India?

Virat Special Steels is the world largest Supplier, Stockiest, Importer and Exporter of H13 Hot Die Block or Hot Work Steel.

H13 has worthy thermal shock resistance and can endure some water freezing in service. Nitriding will improve rigidity. H13 has bigger similarity and an exceptionally fine structure, leading to improved machinability, polishability and high-temperature tensile strength.

About us– With the opening up of the global markets, VIRAT STEELS started importing Tools & Die Steels from the world’s top most manufacturing companies like. M/s Vitkovice , Czech Republic, Deutche Edelstahlwerke from Germany, Somers Forge from England. who recognized trade house. The state of art machines and required infrastructure are being installed at the steel yard at its head office and branches.

H13 tool steel is a versatile chromium-molybdenum hot work steel that’s wide utilized in hot work and cold work tooling applications. the recent hardness (hot strength) of H13 resists thermal fatigue cracking that happens as the results of cyclic heating and cooling cycles in hot work tooling applications.

Due to its wonderful combination of high toughness and resistance to thermal fatigue cracking (also called heat checking) H13 is used for additional hot work tooling applications than the other tool steel.

Because of its high toughness and really sensible stability in heat treatment, H13 Tool Steel is additionally utilized in a spread of cold work tooling applications. In these applications, H13 provides higher hardenability (through hardening in giant section thicknesses) and higher wear resistance than common alloy steels like 4140.

APPLICATIONS: – Inserts, cores, and cavities for die casting dies, die casting shot sleeves, hot forging dies, extrusion dies, and plastic mould cavities and parts that need high toughness and wonderful polishability.

Supplier of H13 Steel– Virat Special Steels Pvt Ltd is the world largest H13 Die steel supplier and stockist that supplies H13 steel to all over the world.

Consult our team at Virat Special Steels, will assist you with any queries you have about H13 Steel. Whether you need flat, square, or round bar shapes, we have the right solution for your needs.

Learn more: https://www.viratsteels.com/h13.html

Contact us today to learn more about our products and services!

📬info@viratsteels.com ☎+91 98140-21775

Exploring Tool and Die Steel Supplier in Faridabad?

When it comes to tool and die steel suppliers in Faridabad, there are several options to explore. Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Faridabad!

Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made solutions. With state-of-the-art plants in #Gurugram and #Ludhiana, they have established a strong distribution network across India.

Available Grades:

- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

Quality Assurance and Examination:

Virat Special Steels has an impressive quality assurance facility, including chemical tests, spectrometry, ultrasonic examinations, and hardness testing. This ensures optimal steel selection for specific applications and cost optimization in the long run.

Make In INDIA:

They offer competitive prices, top-notch quality, and prompt service, positioning themselves as a reliable “Make In INDIA” choice for their customers.

For more information, you can explore their details:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-Faridabad/

Remember to explore this suppliers and find the right fit for your specific tool and die steel requirements in Faridabad!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📧 info@viratsteels.com 📞 +91-98140 21775