Die Steel H13

now browsing by category

Looking for High-quality Aluminium Extrusion Die Steel!

Forge Ahead with Virat’s H13!

The Pinnacle of Durability and Performance in Every Extrusion!

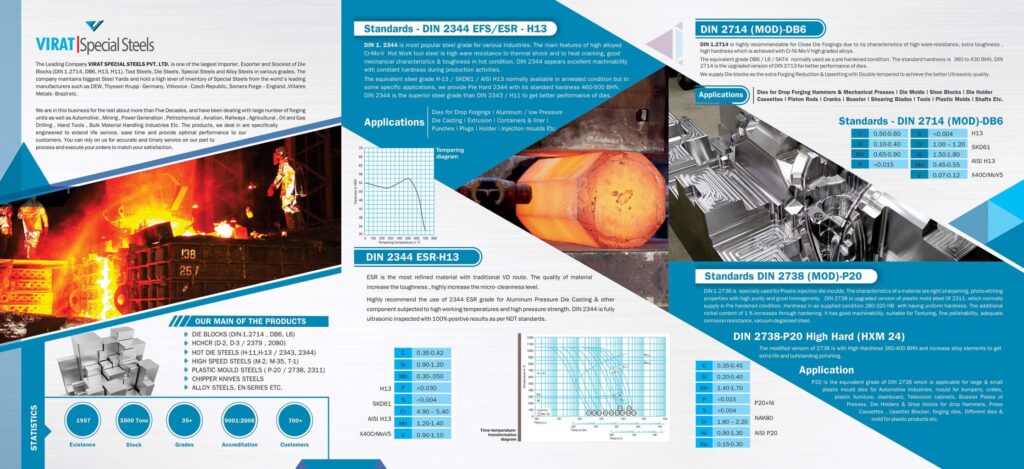

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Application Areas:

- Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

- Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

- Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

Are you looking for Aluminium Extrusion Die Steel in India?

Virat Special Steels Pvt. Limited is a prominent choice. They specialize in high-quality H11 and H13 tool steels, known for their durability and performance in high-temperature applications. These materials are essential for manufacturing processes like die casting, forging, and plastic molding.

Why Choose Virat Special Steels?

- Quality Assurance: Ultrasonic inspection ensures 100% positive results as per NDT standards.

- Specialization: Expertise in H11, H13 / DIN-1.2344, DIN-1.2343 / AISI H11, AISI H13.

- Experience: Over five decades of industry presence.

- Inventory: Ready stock available in various shapes and sizes for immediate needs.

Aluminium extrusion dies are essential tools used in the process of shaping aluminium profiles and components through extrusion. These dies are typically made from high-strength tool steel and are designed to withstand high pressures and temperatures during the extrusion process.

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of H11, H13 / DIN-1.2344 , DIN-1.2343 / AISI H11, AISI H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. All die steel is available in flat, square and round shape.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Any further queries feel free to contact us :

☎+91 098140-21775 🌐www.viratsteels.com

📬 info@viratsteels.com

Tool and Die Steel Supplier, Dealer, Trader in Ahmedabad!

Ahmedabad, the vibrant city in Gujarat, stands as a testament to India’s industrial prowess. Known colloquially as the “Manchester of the East,” it has carved a niche for itself in the textile domain. However, its economic tapestry is far more intricate, encompassing a diverse array of sectors from chemicals to IT.

At the heart of this industrial hub is the tool and die steel industry, a sector that underpins various other industries with its robust materials. Tool and die steel, characterized by its durability and resistance to extreme conditions, is indispensable in manufacturing tools and components for sectors as varied as automotive and aerospace.

Virat Special Steels Pvt. Limited emerges as a beacon of trust within this niche. Their expertise spans across an impressive range of steels, including tool steel, die steel, and high-speed steel. Their commitment to quality is evident in their value-added services like material machining and metallurgical advice.

Their product brochure boasts an array of steel grades available ex-stock, ensuring they cater to immediate industry needs. With facilities in Gurugram and Ludhiana and a formidable distribution network, Virat Special Steels Pvt. Limited stands as a pillar of industrial strength in Ahmedabad‘s economic landscape.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc. Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website:

https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-ahmedabad/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers +91-98140 – 21775, 99991 – 24971 to 79.

How do you choose the right die steel for your forging process?

Choosing the right die steel for your forging process involves several key factors to ensure optimal results and longevity of the dies.

Here are the considerations you should make:

- Strength and Toughness: Select a steel that offers high strength to withstand the stresses of forging without deforming, and toughness to resist cracking under impact.

- Heat Resistance: The steel should maintain its properties at the high temperatures used in forging, preventing premature wear or failure.

- Durability: Consider the wear resistance of the steel, as dies are subject to constant abrasion during the forging process.

- Composition: The alloying elements in the steel, such as chromium, molybdenum, and vanadium, can enhance specific properties like heat resistance and durability.

- Forging Process: The type of forging process (open-die, closed-die, etc.) can influence the choice of steel, as different processes may require different steel properties.

- Work Material: The type, thickness, and hardness of the material being forged will affect the choice of tool steel.

- Production Volume: The number of parts to be produced can also dictate the choice of steel, as high-volume runs may require a steel with greater wear resistance.

- Cost: Balance the cost of the steel with the performance requirements. More expensive steels may offer better performance but could be overkill for less demanding applications.

By carefully considering these factors, you can select a die steel that meets the specific needs of your forging process and contributes to the overall success of your operation. Remember to consult with steel suppliers or specialists if you need more detailed advice tailored to your particular situation.

Are you looking for Drop Forging Press #DieSteelH13?

H13 tool steel is a widely used die steel for drop forging presses, known for its excellent properties such as high toughness, thermal fatigue resistance, and high hardenability. It’s particularly well-suited for applications that require resistance to thermal shock and cracking, making it ideal for the harsh conditions of drop forging.

If you’re in need of H13 tool steel for your drop forging press, Virat Special Steels offers a comprehensive range of H13 steel in various shapes and sizes to meet your requirements. With options in flat, square, and round bar forms, they can cater to any specific needs you might have.

For personalized assistance and to address any queries regarding H13 steel, don’t hesitate to reach out to the Virat Special Steels team. They are equipped to provide you with expert guidance and support.

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com