DIN 2344

now browsing by category

Global Quality With NLMK . Local Reliability With Virat Steels.

In today’s competitive manufacturing sector, material quality is truly a important parameter. For toolmakers, die manufacturers, and OEM suppliers, the difference between consistent output and recurring failure often begins with the quality of tool steel.

For decades, European tool and die steels have been set global benchmarks for their performance, reliability, and longevity. Today, that same European steel excellence is no longer distant or difficult to access—it is now locally available in Virat Steels – India, backed by trusted partnerships and reliable supply chains.

European Tool Steel: A Proven Benchmark –

European tool steel manufacturers—particularly NLMK Verona—are globally recognized for their strict quality control, advanced refining processes, and consistent heat-treatment performance.

These superior metallurgical standards deliver:

- longer die and mould life

- Excellent toughness and hardness balance

- Superior surface finish after machining

- Lower rejection rate

The result is predictable performance, higher productivity, and long-term cost efficiency for demanding tooling applications.

Now Local Availability with Trusted Indian Support –

With 70+ years of experience in metal domain, Virat Steels is a trusted & successful pan-India supplier of tool and die steels backed by 3 regional stocking yards, 3,500+ tons of inventory, and advanced cutting facilities, ensuring fast and reliable deliveries.

The company remains committed to delivering premium grades such as: DIN 1.2714 | 1.2344 | 1.2738 | 1.2379 | HSS M2, M35 , T1 and more ensuring availability even during periods of market volatility and steel shortages.

By combining European manufacturing excellence with strong local service and technical expertise, Virat Steels enables Indian toolmakers to compete confidently on a global level now easily accessible with:

- consistent quality with premium metallurgical properties

- reliable supply, even during market shortages

- proven performance material in critical applications

- complete documentation and traceability

If you are looking to upgrade your tooling materials and align with global level, now is the time to experience European tool steel—locally supported, reliably supplied, and technically assured by Virat Steels.

Please Consult our office for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Ph: 98140 – 21775, 99991 – 24971 to 80 , 92163-21771 to 79.

The Future of Tool Steel: Innovations with DIN 2344 and H13

In the evolving world of manufacturing, the materials used to shape, mold, and cut have a direct impact on productivity and quality. Tool steels play a critical role in this landscape, with DIN 2344 and H13 standing out as industry leaders. Known for their exceptional thermal resistance, hardness, and strength, these grades are the backbone of tools, molds, and dies in industries such as automotive, aerospace, and die-casting. In this article, we’ll explore the significance of these materials, examine ongoing innovations, and understand how companies like Virat Special Steels contribute to shaping the future of tool steel.

The Role of Tool Steel in Manufacturing and Industry

Tool steels are indispensable for industries that demand precision and durability. Used extensively in the production of cutting tools, molds, and dies, these alloys must endure extreme conditions, from high temperatures to heavy wear. Without them, high-quality manufacturing would simply not be possible. Automotive industries rely on tool steels for die-casting, while aerospace engineering depends on these materials for components exposed to high temperatures and stresses. In short, tool steels are the unsung heroes enabling modern engineering feats.

What Makes DIN 2344 and H13 Stand Out?

Composition and Properties of DIN 2344

DIN 2344 is a chromium-molybdenum-vanadium alloyed steel prized for its high thermal resistance and toughness. It maintains hardness even at elevated temperatures, making it a preferred choice for hot-working tools like forging dies and extrusion presses. Key properties include:

- Exceptional wear resistance.

- High tensile strength.

- Excellent machinability.

Characteristics and Features of H13

H13 steel, part of the H-series family, is well-known for its versatility and toughness. It’s often chosen for die-casting and plastic mold tooling, thanks to its outstanding thermal fatigue resistance and ease of fabrication. Its main properties are:

- Superior thermal conductivity.

- Resistance to cracking under repeated heating and cooling cycles.

- High flexibility for complex shaping.

Innovations Driving the Future of Tool Steel

The tool steel industry has seen several groundbreaking advancements. Let’s delve into some of the most significant ones:

- Advanced Alloying Techniques

Researchers are experimenting with alloying elements like cobalt and niobium to improve the thermal and wear resistance of tool steels. Such innovations push the limits of performance. - Additive Manufacturing and 3D Printing

3D printing is revolutionizing tool steel production by enabling intricate designs and reducing material waste. Industries are now combining traditional methods with 3D technologies for optimal results. - Improved Heat Treatment Processes

Heat treatment plays a pivotal role in enhancing tool steel properties. Modern techniques such as vacuum hardening ensure precision in achieving desired hardness and toughness.

Advantages of Modern Tool Steel Innovations

New innovations in DIN 2344 and H13 steels offer several benefits:

- Durability: These steels withstand high temperatures and extreme pressures without significant wear.

- Longevity: Enhanced resistance to thermal fatigue and cracking translates into longer tool lifespans, reducing downtime and maintenance costs.

- Efficiency: Advanced manufacturing techniques improve energy usage and reduce material waste.

Comparing DIN 2344 and H13 Tool Steels

Below is a snapshot of their key differences:

| Property | DIN 2344 | H13 |

| Composition | Cr, Mo, V | Cr, Mo, Si, V |

| Thermal Resistance | High | Very High |

| Applications | Forging, extrusion | Die-casting, molds |

Applications of DIN 2344 and H13

Both steels are tailored to specific needs:

- DIN 2344: Ideal for extrusion tooling and hot forging, thanks to its resistance to thermal shock.

- H13: Perfect for plastic injection molding, die-casting, and high-temperature aerospace components.

Environmental Sustainability and Tool Steels

Modern practices focus on sustainability. From reducing energy-intensive processes to emphasizing recycling, the industry is working toward a smaller environmental footprint. The longevity of DIN 2344 and H13 further minimizes the need for replacements, aligning with eco-friendly goals.

Future Prospects of DIN 2344 and H13

As industries move toward automation and more advanced technologies, the demand for high-performing materials like DIN 2344 and H13 is set to rise. Innovations in metallurgy and 3D printing will only increase their applications.

Challenges in the Tool Steel Industry

Despite advancements, challenges persist. Manufacturers face supply chain disruptions, the rising cost of raw materials, and the need to balance quality with affordability. Addressing these challenges requires collective efforts from stakeholders, including suppliers like Virat Special Steels.

The Role of Companies Like Virat Special Steels

Virat Special Steels is a pioneer in the distribution of high-quality tool steels, including DIN 2344 and H13. By committing to innovation, stringent quality checks, and customer satisfaction, they remain at the forefront of the industry.

Key Takeaways

- Tool steels like DIN 2344 and H13 are integral to modern manufacturing.

- Innovations are enhancing their performance and extending their applications.

- Companies like Virat Special Steels are instrumental in meeting the growing demands of the industry.

FAQs About Tool Steel

- What makes DIN 2344 unique compared to other tool steels?

Its ability to maintain hardness at high temperatures and resist wear sets it apart. - Why is H13 preferred in certain industries?

H13 combines versatility and thermal fatigue resistance, making it ideal for die-casting and molds. - How does Virat Special Steels ensure the quality of its products?

Rigorous testing, advanced manufacturing techniques, and expert handling ensure top-notch quality. - Can DIN 2344 and H13 be recycled efficiently?

Yes, their high-grade compositions make them suitable for recycling without significant loss of quality. - What industries are likely to adopt future innovations in tool steels?

Automotive, aerospace, and renewable energy sectors will likely benefit the most.

Virat Special Steels is the largest Supplier & Stockiest of H13 Steel in India. Consult our team who will assist you for H-13/ DIN 2344 / AISI H13 steel query. https://www.viratsteels.com/h13.html

Size Range in Forged / Rolled Bars:

Rounds: 13mm Dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

For more information or to discuss your steel needs, Virat Special Steels invites you to reach out through their contact details provided, ensuring a professional and informative experience.

Any further queries feel free to contact us :

🌐https://www.viratsteel.in 📬 info@viratsteels.com ☎+91 98140-21775

Critical Applications of DIN 2344 Steel in the Automotive Industry!

Steel remains the backbone of the automotive industry, providing the strength and resilience required for modern vehicles. Among the various grades of steel used, DIN 2344 steel holds a prominent place due to its exceptional performance under challenging conditions. This article explores the critical applications of DIN 2344 steel in the automotive industry, showcasing why it is a preferred material for manufacturers globally.

What is DIN 2344 Steel?

DIN 2344 steel, also known as H13 tool steel, is a versatile, high-performance material widely utilized in hot work applications. Classified as a chromium-molybdenum steel alloy, it is specially engineered for superior heat resistance, toughness, and wear properties.

Key Properties of DIN 2344 Steel

- Thermal Resistance: With its ability to retain strength and hardness at elevated temperatures, DIN 2344 is perfect for high-heat environments.

- Toughness and Durability: Its superior toughness makes it resistant to cracking and deformation.

- Corrosion Resistance: With strong resistance against oxidizing environments, it outperforms many other alloys.

- Machinability: While challenging to machine, advanced processes have streamlined its incorporation in various automotive applications.

Importance of DIN 2344 Steel in Modern Industry

The global shift toward lightweight yet robust materials has spotlighted DIN 2344 steel, particularly in automotive manufacturing. With its combination of toughness and flexibility, it meets the demands of advanced production lines.

Relevance of DIN 2344 Steel in Automotive Manufacturing

1. Historical Context of Material Usage in Automotive Engineering

Steel has evolved over decades as the material of choice in automotive engineering. From basic carbon steels to high-alloy steels like DIN 2344, each advancement reflects a need to address emerging challenges, including efficiency, safety, and sustainability.

2. Why DIN 2344 is Perfect for the Automotive Sector?

The automotive industry faces constant pressure to produce durable, efficient, and lightweight vehicles. DIN 2344 steel meets these demands with its remarkable properties, offering enhanced strength for components that endure high-stress conditions.

Applications of DIN 2344 Steel in Automotive Components

- Use in Die Casting Tools: Die casting forms a vital part of automotive manufacturing, especially for producing lightweight engine and body components.

- Significance in Aluminum and Magnesium Alloy Casting. DIN 2344 steel excels in die-casting tools used for aluminum and magnesium alloys, offering superior wear resistance and prolonging tool life in high-temperature operations.

- Molds for Plastic Injection: As plastics gain traction in automotive design, durable molds made from DIN 2344 steel ensure precise shaping of components, contributing to reduced production defects and downtime.

- Hot Forming and Forging Applications: DIN 2344 steel is indispensable in hot forming and forging operations due to its ability to maintain hardness and strength even at elevated temperatures.

- Applications in Exhaust Systems and Engine Components:

- Enhanced Durability in High-Temperature Environments: From turbochargers to exhaust manifolds, DIN 2344 steel ensures resistance to thermal fatigue, ensuring reliability in extreme engine environments.

Benefits of Using DIN 2344 Steel

- High Wear Resistance: The wear resistance of DIN 2344 enhances the lifespan of tools and components, reducing frequent replacements and minimizing downtime.

- Excellent Thermal Stability: DIN 2344 steel maintains its structural integrity under high-temperature operations, a critical advantage for heat-intensive automotive processes.

- Corrosion Resistance: Superior resistance to oxidation and other corrosive agents ensures long-term durability, even under severe operating conditions.

- Cost-Effectiveness in Automotive Production: Reduced downtime, longer tool life, and enhanced product performance result in significant cost savings for manufacturers.

Challenges and Considerations

- Machining and Heat Treatment Challenges: While offering unmatched performance, DIN 2344 steel poses challenges in machining and heat treatment. Manufacturers must employ specialized techniques to overcome these hurdles.

- Alternatives to DIN 2344 Steel: In scenarios where DIN 2344 isn’t suitable, alternatives such as D2 or P20 steels might be considered based on specific application requirements.

Innovations and Future Applications

- Emerging Automotive Trends Impacting Material Choice: Electric vehicles and lightweight design trends are shaping the use of advanced steels, with DIN 2344 continuing to play a pivotal role.

- Future-Ready Technologies Enabled by DIN 2344 Steel: From 3D-printed automotive parts to precision components for EVs, the versatility of DIN 2344 opens pathways for innovative designs.

Sustainability and Environmental Impact

- How DIN 2344 Supports Energy Efficiency: The durability of DIN 2344 reduces waste in production, while its energy-efficient processing ensures environmentally friendly manufacturing practices.

- Recycling and Reusability in the Automotive Supply Chain: DIN 2344 steel components can be recycled and reused, supporting circular economy principles and reducing the industry’s carbon footprint.

Conclusion:

DIN 2344 steel stands as a cornerstone in the automotive industry, enabling the creation of high-performance vehicles and components. With its unique properties and adaptability, it continues to shape the future of manufacturing.

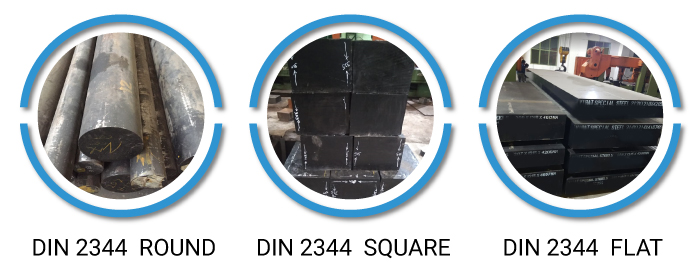

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of DIN 2344 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2344 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2344 steel query.

FAQs

- What makes DIN 2344 steel ideal for the automotive industry?

Its exceptional heat resistance, wear resistance, and durability make it indispensable for high-stress applications like die-casting and forging tools. - Can DIN 2344 steel withstand extreme temperatures in engine systems?

Yes, DIN 2344 offers excellent thermal stability and is ideal for components in high-temperature environments, such as exhaust systems. - How does DIN 2344 steel contribute to cost-efficiency in manufacturing?

Its durability and wear resistance minimize tool replacement costs, reducing downtime and production expenses. - Are there eco-friendly aspects to using DIN 2344 steel in automotive production?

Yes, its recyclability and reduced waste in the production process support sustainable manufacturing practices. - What are the alternatives if DIN 2344 steel isn’t viable?

D2 or P20 steels are viable alternatives, depending on application needs and operating conditions.

Exploring H13 Tool Steel Properties, Applications and Machining!

In the world of industrial tooling, H13 tool steel stands out as a versatile and high-performance material, essential for applications requiring exceptional hardness, toughness, and resistance to thermal fatigue. At Virat Special Steels, we specialize in providing quality H13 steel and expert support to meet diverse industry needs, whether for die casting, molding, or forging applications. This blog explores the key properties, applications, and machinability of H13 tool steel, which make it a go-to solution for tooling requirements worldwide.

Understanding H13 Tool Steel

H13 tool steel is a chromium-molybdenum-vanadium alloy, specifically engineered for high-stress applications, particularly in environments with elevated temperatures. Known for its unique balance of hardness, toughness, and heat resistance, H13 is widely used in die casting and hot forging tools where it faces constant wear and thermal cycling.

Here are some of the notable properties of H13 steel that make it so valuable:

- Hot Work Capability: H13 is classified as hot work tool steel, designed to withstand high temperatures and repetitive heating and cooling cycles.

- Excellent Hardness: H13 tool steel hardness is in the range of 44-54 HRC, depending on heat treatment, which allows it to resist deformation under high-stress conditions.

- Good Toughness: H13 offers a high level of impact resistance, which is essential for tools that encounter high-pressure and high-speed operations.

- Enhanced Thermal Fatigue Resistance: The steel’s composition and structure allow it to withstand thermal cycling without cracking, which is ideal for die casting and extrusion dies.

Applications of H13 Tool Steel

Due to its ability to endure high temperatures and maintain structural integrity under stress, H13 steel is widely used across various industrial sectors.

Some of its primary applications include:

- Die Casting Dies: Its resistance to thermal fatigue and wear makes H13 ideal for molds used in die casting, where repeated exposure to molten metals demands a material that won’t degrade under high heat.

- Forging Dies: H13’s toughness and hardness are suited for hot forging, where tools must withstand high impact and compressive forces.

- Extrusion Tools: H13 is frequently used for tools involved in the extrusion of metals due to its durability and ability to withstand high-pressure environments.

- Plastic Molding Dies: In plastic molding, H13 is used for molds that need to withstand both high temperatures and pressures while producing intricate shapes.

Machining H13 Tool Steel: Tips and Techniques

Machining H13 tool steel requires specific considerations due to its hardness and toughness.

Here are some strategies that can help optimize machining processes with H13:

- Use of Carbide Tools: Given its hardness, H13 should ideally be machined with high-quality carbide cutting tools to ensure precision and reduce tool wear.

- Moderate Speeds and Feeds: For effective machining, it’s recommended to use moderate cutting speeds and feeds to prevent overheating and maintain tool integrity.

- Coolant Utilization: Applying a coolant during machining helps reduce heat build-up, especially in high-speed operations, which can protect both the tool and workpiece.

- Heat Treatment: To improve machinability, H13 is typically machined in its annealed state and then heat-treated to achieve the desired hardness for its end application.

Why Choose Virat Special Steels for H13 Tool Steel?

At Virat Special Steels, we are committed to providing top-quality H13 tool steel tailored to meet the demands of your applications. Our expertise in steel distribution, coupled with our focus on high standards and customer support, ensures that you receive only the best material, whether you need H13 die steel, mold steel, or hot work tool steel.

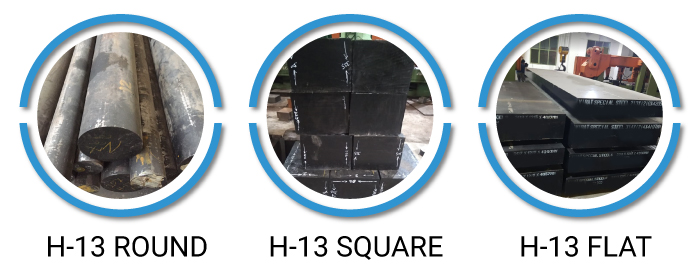

Our team of experts is here to help guide you through selecting the right material for your needs, offering insights on H13 material properties, mechanical properties, and recommendations for machining and heat treatment. Virat Special Steels is the largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website https://www.h13steel.in / https://www.viratsteels.com/h13.html

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📲 +91-98140 21775

Exploring the Best Tool and Die Steel Supplier in Secunderabad!

Secunderabad, the vibrant twin city of Hyderabad, is not only steeped in history but also thrives as a modern industrial hub. Its strategic location in the northern part of Hyderabad, demarcated by the iconic Hussain Sagar Lake, has historically made it a focal point for various economic activities.

The city’s origins date back to the British era, where it served as a cantonment for the British Indian Army. Named after Sikandar Jah, the third Nizam of the Asaf Jahi dynasty, Secunderabad has since evolved into a bustling economic center. Its industrial landscape is marked by a diverse range of activities, contributing significantly to the region’s economic prowess.

One of the key industrial sectors that Secunderabad is renowned for is the tool and die steel industry. This sector is crucial for the manufacturing of precision tools, dies, molds, and components essential for the metalworking, automotive, aerospace, and other high-precision engineering industries.

Among the prominent players in this field is Virat Special Steels Pvt. Limited, a company that has carved a niche for itself in the supply of various grades of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their commitment to providing value-added services, such as material machining, cut pieces, and tailor-made solutions, sets them apart. Moreover, their emphasis on metallurgical expertise and quality assurance underscores their dedication to excellence.

With state-of-the-art facilities in Gurugram and Ludhiana, and a robust distribution network across India, Virat Special Steels exemplifies the industrial vigor of Secunderabad. Their presence not only bolsters the city’s industrial fabric but also serves as a testament to the region’s ongoing development and urban planning initiatives.

Wide Range of Materials:

Virat Special Steels deals in various steel types, including:

- Tool Steel: DB6 / DIN-1.2714 / AISI L6, essential for cutting, shaping, and forming tools.

- Die Steel: DIN 2343, 2344 / AISI H11, H13, crucial for molds, dies, and precision components.

- Plastic Mold Steel: DIN 2738, 2311 , AISI P 20, tailored for plastic injection molding.

- High-Speed Steel: DIN 3243 , 3343 / AISI M2 , M35, ideal for high-speed machining.

- Alloy Steel: Versatile and robust for diverse applications.

Value-Added Services:

They go beyond supplying raw materials. Their services include:

– Material Machining: Precision shaping and customization.

– Cut Pieces: Ready-to-use segments for efficiency.

– Tailor-Made Material: Customized to specific requirements.

Metallurgical Expertise:

Virat Special Steels provides metallurgical advice to ensure optimal material selection and performance.

Their team understands the nuances of steel properties and applications.

Quality Assurance:

Quality is non-negotiable. They adhere to stringent standards.

Ultrasonic inspection ensures material integrity.

State-of-the-Art Facilities:

Their Gurugram and Ludhiana plants boast cutting-edge technology.

Consistent quality and timely delivery are their hallmarks.

Strong Distribution Network:

Virat Special Steels reaches across India, ensuring accessibility.

Whether in Secunderabad or Hyderabad or beyond, their steel is within reach.

For more information, visit Virat Special Steels. Trust in their expertise for all your steel needs! 🛠️🔥

Consultation:

For further assistance, consult their #Gurugram office. Learn more https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-secunderabad/

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

As Secunderabad continues to grow and attract various industries, the tool and die steel sector remains a cornerstone of its industrial identity, driving innovation and supporting the intricate needs of precision engineering fields.

For those interested in exploring the offerings of Virat Special Steels Pvt. Limited, further information can be sought through their corporate channels, as they continue to play a pivotal role in the industrial narrative of Secunderabad.

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📨 info@viratsteels.com 📞 +91 098140-21775

Navigating the Tool and Die Steel Market in Dubai!

The tool and die steel industry in Dubai is a critical component of the manufacturing sector, playing a pivotal role in shaping the emirate’s industrial landscape. The demand for tool and die steel is closely tied to the overall health of the economy, particularly in sectors such as construction, infrastructure development, and manufacturing.

The UAE steel market has been projected to experience significant growth from 2020 to 2026, spurred by an increase in construction activities and infrastructure projects. This growth is expected to boost the demand for tool and die steels, which are essential for producing a wide array of steel products and components. However, the industry faces challenges, including heavy reliance on steel imports, primarily from India, which makes up approximately 95% of the UAE’s steel imports. This dependence subjects the local market to the volatility of international steel prices and the intricacies of trade policies.

To mitigate these challenges, there is a pressing need for the UAE to bolster its domestic steel production capabilities, particularly for specialized and customized tool and die steels. Developing a robust local production can reduce reliance on imports, stabilize the market, and potentially lead to more competitive pricing.

One notable supplier from India that has made a mark in the Dubai market is Virat Special Steels Pvt. Limited. The company offers a comprehensive range of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their value-added services, such as material machining, provision of cut pieces, and tailor-made materials, coupled with metallurgical advice and quality assurance, position them as a reliable partner for businesses in Dubai seeking high-quality tool and die steel solutions.

As Dubai continues to expand its industrial capabilities, the tool and die steel sector will undoubtedly play a crucial role. Companies like Virat Special Steels Pvt. Limited are well-positioned to meet the growing demands and contribute to the emirate’s economic growth. The future of tool and die steels in Dubai hinges on strategic investments, innovation, and the development of a self-reliant steel industry that can support the emirate’s ambitious industrial goals.

The following grades of steel are available with them on an ex-stock basis:

- 1. DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- 2. HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- 3. PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- 4. HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- 5. COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- 6. ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Consult our Gurugram office in India for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Industry’s Guide to Selecting the Right Hot Work Tool Steel!

In the dynamic world of manufacturing, selecting the right materials is crucial for success. Hot work tool steels are a critical component in this process, especially for industries that shape metals under high temperatures. These steels are designed to withstand the rigorous conditions of cutting and molding heated metals, making them indispensable for manufacturers.

Virat Special Steels stands out as a beacon in the supply of hot work tool steels, such as DB6, H13, and H11. Their extensive inventory and expertise make them a go-to for industries in need of high-quality materials that can endure the heat, beat, and repeat cycle of manufacturing processes.

Understanding the unique properties of hot work tool steels like DB6, H13, H11, and H21 is essential. For instance, H13 is renowned for its exceptional heat resistance, toughness, and wear resistance, making it ideal for die casting dies and extrusion tools. These characteristics are vital for maintaining the integrity of tools and ensuring the consistency of manufactured products.

Virat Special Steels offers these materials in various forms, including flat, square, and round bars, catering to diverse manufacturing needs. Their mode of supply ensures that manufacturers have access to the right type of steel in the required shape, enhancing the efficiency of production lines.

For manufacturers looking to push the boundaries of what’s possible, partnering with knowledgeable suppliers like Virat Special Steels is a step towards achieving superior results. With the right hot work tool steel, the future of manufacturing looks bright, shaped by the principles of heat, beat, and repeat.

For detailed guidance and assistance in selecting the perfect hot work tool steel for your manufacturing needs, consulting with the experts at Virat Special Steels is highly recommended. Their team is equipped to handle queries and provide solutions that propel manufacturing operations to new heights.

Embrace the future of manufacturing with the right materials and expertise, and watch your operations transform with the power of hot work tool steel.

Contact us today to learn more!

https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

Exploring the Versatility of H13 Die Steel in Industrial Applications!

In the world of industrial manufacturing, the quest for materials that can withstand extreme conditions while maintaining integrity is perpetual. Among the various contenders, H13 die steel emerges as a frontrunner, especially in the realm of aluminum extrusion die steel H13. Virat Special Steels Pvt. Limited, a company with over five decades of expertise, stands at the forefront of supplying this high-grade steel known for its remarkable properties.

H13 tool steel is a chromium-molybdenum-vanadium hot work steel that is prized for its ability to resist thermal fatigue due to its excellent heat resistance, hardness, and toughness. These characteristics make it an ideal choice for several critical industrial applications.

In die casting, H13’s resilience under high temperatures and pressures makes it the recommended choice for aluminum pressure die casting. Its robustness ensures the longevity of the dies, which is crucial for maintaining production efficiency and reducing downtime.

The forging industry also benefits from H13’s properties. The steel’s capacity to withstand rapid cooling and resist heat checking is essential for forging dies, which are subjected to severe thermal cycles.

Moreover, the plastic industry utilizes H13 in injection molding processes, where its high polishability is a significant advantage for creating molds that yield aesthetically pleasing and precise plastic products.

Virat Special Steels underscores its commitment to quality by ensuring that their H13 steel undergoes a rigorous ultrasonic inspection, adhering to NDT standards and guaranteeing 100% positive results. This level of quality assurance is vital for industries where safety and reliability are paramount.

The company’s extensive experience is complemented by its readiness to serve clients, with a well-maintained inventory that promises immediate availability of H13 steel, facilitating uninterrupted industrial operations.

For businesses looking to enhance their manufacturing processes with a material that offers durability and performance, Virat Special Steels Pvt. Limited presents itself as a reliable partner. Their provision of H13 tool steel is not just a product offering; it’s a testament to their dedication to quality and service in the industrial sector.

To explore how Virat’s H13 can revolutionize your production capabilities, visit their website or contact their team for more information and expert guidance. Forge ahead with confidence, knowing that your operations are powered by the pinnacle of durability and performance.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us:

🌐https://www.viratsteels.com 📬info@viratsteels.com ☎+91 98140-21775

Exploring the Tool and Die Steel Supplier in Ambattur!

Ambattur, although recognized for its industrial activities, is part of the larger urban fabric of Chennai. As Chennai continues to grow, Ambattur plays a role as both an industrial and residential hub within the expanding metropolitan area. It is also known for its industrial development and urban planning. Ambattur has some tools and die steel industries that manufacture and supply various types of tools, dies, molds, and other components for various industries such as automotive, aerospace, medical, etc.

Ambattur’s industrial prowess is particularly evident in its tool and die steel sector, which serves a myriad of industries, including automotive, aerospace, and medical. Among the notable companies in this sector is Virat Special Steels Pvt. Limited, renowned for its comprehensive range of products, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. The company distinguishes itself by offering value-added services such as material machining, provision of cut pieces, and tailor-made material solutions. Furthermore, Virat Special Steels is lauded for its metallurgical expertise and unwavering commitment to quality assurance.

One of the best Tool & Die Steels Supplier in Ambattur city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

For more information, you can explore their website:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-ambattur/

Consult our Gurugram office for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Contact them by mobile numbers +91-98140 – 21775, 99991 – 24971 to 79.

Exploring the Tool and Die Steel Supplier in Coimbatore!

Coimbatore, a bustling city in Tamil Nadu, India, is not only a cultural and historical beacon but also a thriving hub for various industries. Known predominantly for its textile industry, engineering goods, and agricultural products, Coimbatore has carved out a significant niche in the industrial sector of India. As the second-largest city in Tamil Nadu and the 16th largest urban agglomeration in the country, it stands as a testament to India’s rapid industrial development and urban planning.

The city’s industrial landscape is diverse, with a strong presence of tool and die steel industries that are crucial for the metalworking, automotive, aerospace, and precision engineering fields. These industries cater to the demand for high-quality tools, dies, molds, and other components that are essential for manufacturing processes across various sectors.

One of the best Tool and Die Steels Suppliers in Coimbatore city . The prominent players in this sector is Virat Special Steels Pvt. Limited, a company that has established itself as a leading supplier of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their commitment to providing value-added services such as material machining, cut pieces, and tailor-made material solutions sets them apart in the industry. Moreover, their focus on offering metallurgical advice and ensuring quality assurance underscores their dedication to customer satisfaction and product excellence.

Product Range:

- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. Virat Special Steels exemplifies the industrial spirit of Coimbatore. Their role in the tool and die steel supply chain underscores the town’s status as a hub of industrial activity and innovation. They also have a strong distribution network across India.

For more information, you can explore here: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-coimbatore/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎+91 98140-21775