DIN 2344

now browsing by category

Tool and Die Steel Supplier in Bhiwadi, Rajasthan!

Bhiwadi, a city that has strategically positioned itself as a cornerstone of industrial development in the Indian state of Rajasthan, is rapidly emerging as a hub for forging excellence and crafting precision. With its roots deeply embedded in the rich cultural heritage of India, Bhiwadi is not just a city that echoes the past through its historical monuments like the Bhangarh Fort and the Sariska Tiger Reserve but is also a beacon of modern industrialization.

The city’s strategic location on the Rajasthan-Haryana border, just 85 km from Alwar, has made it an attractive destination for Taiwanese and Japanese companies, fostering a unique blend of global industrial practices with local expertise. The population of approximately 600,000 people boasts a commendable literacy rate of 79.84%, reflecting the city’s emphasis on education and skill development, which are critical to sustaining industrial growth.

At the heart of Bhiwadi’s industrial prowess are its steel industries, which have become synonymous with reliability and quality. These industries specialize in manufacturing a variety of steel products, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. These materials are known for their enhanced properties such as strength, hardness, wear resistance, and toughness, making them indispensable for producing tools, dies, molds, and other components that demand high performance and durability.

One company that stands out in this competitive landscape is Virat Special Steels Pvt. Limited, a company that has become a trusted name in the steel industry. Their expertise covers a wide range of steels, including tool steel, die steel, and high-speed steel. What sets Virat Special Steels apart is their unwavering commitment to quality, which is evident in their value-added services such as material machining and metallurgical advice.

Virat Special Steels‘ product brochure is a testament to their readiness to meet immediate industry needs, showcasing an extensive array of steel grades available ex-stock. With state-of-the-art facilities in Gurugram and Ludhiana and a robust distribution network, the company has established itself as a pillar of industrial strength, not just in Bhiwadi but across the economic landscape of Ahmedabad.

The city of Bhiwadi, with its blend of historical significance and industrial dynamism, is a testament to India’s growth story. It is a city where tradition and progress go hand in hand, forging a path of excellence and precision that is unmatched. As Bhiwadi continues to evolve, it remains a symbol of India’s potential to excel in the global industrial arena, offering unbeatable prices and unmatched quality.

The following grades of steel are available with them on an ex-stock basis:

1. DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

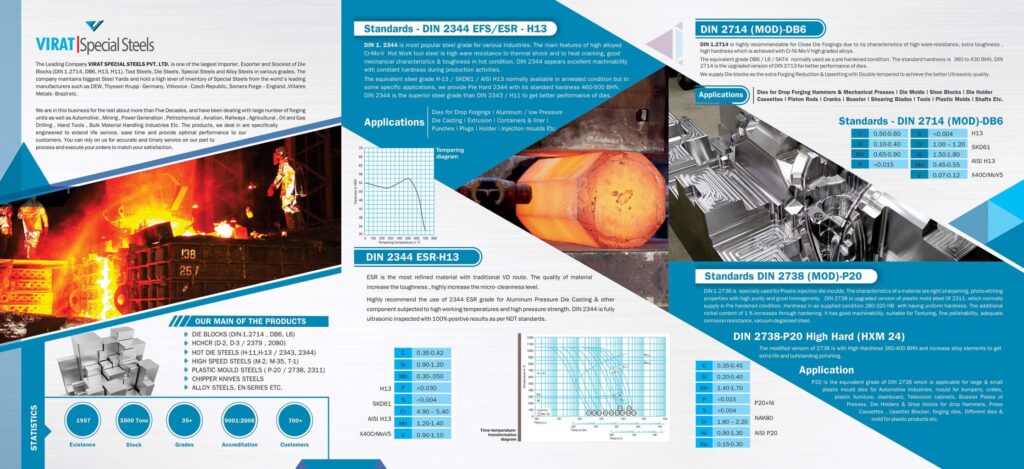

2. HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

3. PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

4. HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

5. COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

6. ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc. Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website: https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-bhiwadi/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers +91-98140 – 21775, 99991 – 24971 to 79.

Get Tool and Die Steel Supplier in Bhiwadi, Rajasthan Now!

Fill this Form:

https://docs.google.com/forms/d/1JQchjfYhLG6REapskrGIrTWnVfe_T8rHahbP3q11VJE/prefill

Thanks

How do you choose the right die steel for your forging process?

Choosing the right die steel for your forging process involves several key factors to ensure optimal results and longevity of the dies.

Here are the considerations you should make:

- Strength and Toughness: Select a steel that offers high strength to withstand the stresses of forging without deforming, and toughness to resist cracking under impact.

- Heat Resistance: The steel should maintain its properties at the high temperatures used in forging, preventing premature wear or failure.

- Durability: Consider the wear resistance of the steel, as dies are subject to constant abrasion during the forging process.

- Composition: The alloying elements in the steel, such as chromium, molybdenum, and vanadium, can enhance specific properties like heat resistance and durability.

- Forging Process: The type of forging process (open-die, closed-die, etc.) can influence the choice of steel, as different processes may require different steel properties.

- Work Material: The type, thickness, and hardness of the material being forged will affect the choice of tool steel.

- Production Volume: The number of parts to be produced can also dictate the choice of steel, as high-volume runs may require a steel with greater wear resistance.

- Cost: Balance the cost of the steel with the performance requirements. More expensive steels may offer better performance but could be overkill for less demanding applications.

By carefully considering these factors, you can select a die steel that meets the specific needs of your forging process and contributes to the overall success of your operation. Remember to consult with steel suppliers or specialists if you need more detailed advice tailored to your particular situation.

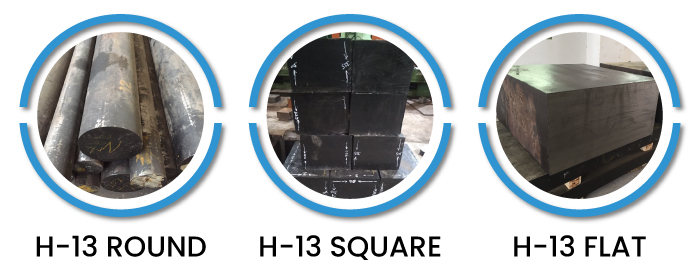

Are you looking for Drop Forging Press #DieSteelH13?

H13 tool steel is a widely used die steel for drop forging presses, known for its excellent properties such as high toughness, thermal fatigue resistance, and high hardenability. It’s particularly well-suited for applications that require resistance to thermal shock and cracking, making it ideal for the harsh conditions of drop forging.

If you’re in need of H13 tool steel for your drop forging press, Virat Special Steels offers a comprehensive range of H13 steel in various shapes and sizes to meet your requirements. With options in flat, square, and round bar forms, they can cater to any specific needs you might have.

For personalized assistance and to address any queries regarding H13 steel, don’t hesitate to reach out to the Virat Special Steels team. They are equipped to provide you with expert guidance and support.

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

Are you looking for trusted Tool and Die Steel Supplier in Pune?

Pune is a city located in the western Indian state of Maharashtra. It is one of the most populous cities in the state and is known for its rich history, cultural heritage, and rapid urban development. Pune is located on the Deccan Plateau. It is the second-largest city in the state and the ninth-most populous city in India. Pune is known as the cultural capital of Maharashtra and the Oxford of the East, because of its many educational institutions and historical landmarks.

Pune is a city in the state of Maharashtra, India. It is also known for its industrial development and urban planning. Pune has some tools and die steel industries that manufacture and supply various types of tools, dies, molds, and other components for various industries such as automotive, aerospace, medical, etc.

One of the best Tool & Die Steels Supplier in Pune city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India. You can visit their website: www.viratsteels.com

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc.

Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website:

https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-pune/

Consult our Gurugram & Pune office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers +91- 98140 – 21775, 99991 – 24971 to 79.

Prominent and high-quality Tool and Die Steel Supplier in Jamshedpur

Jamshedpur is the largest and most populous city in Jharkhand and the first planned industrial city in India. Jamshedpur is a major industrial city located in the East Singhbhum district of Jharkhand, India. It is one of the largest and most populous cities in the state and holds significant importance as an industrial and economic center. It was founded by Jamsetji Tata, the founder of the Tata Group, and named after him.

Jamshedpur is renowned for its industrial landscape and is often referred to as the “Steel City of India.” The Tata Steel plant, one of the oldest and largest steel plants in the country, is a major contributor to the city’s economy. Other industries include automotive manufacturing, cement production, and various engineering and manufacturing units..

Jamshedpur is industrial city in the state of Jharkhand , India. It is also known for its industrial development and urban planning. Jamshedpur has some tools and die steel industries that manufacture and supply various types of tools, dies, molds, and other components for various industries such as automotive, aerospace, medical, etc.

Allow me to introduce one of the prominent Tool & Die Steels Suppliers in Jamshedpur:

One of the best Tool & Die Steels Supplier in Jamshedpur Tata Steel city is: Virat Special Steels Pvt. Limited This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc.

Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website:

https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-jamshedpur/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Are you looking for Tool and Die Steel Supplier in Manesar!

Manesar is a planned city and a municipal corporation in the Gurugram district of Haryana, India. It is part of the National Capital Region of Delhi and an industrial hub with many multinational corporations. It was founded in 1976 and has grown rapidly in the past few decades. It has a population of about 23,000 and covers an area of 124 square kilometers.

Manesar is a planned city and an industrial hub in Haryana, India. It has many multinational corporations and startups in various sectors, such as automobile, IT, BPO, banking, finance, manufacturing, and more. Manesar is a city in Haryana, India, that has many steel industries. Some of the companies that manufacture or supply steel products in Manesar. Tool and die steel are types of steel that are used for making various industrial tools and dies. Tools and dies are devices that are used to cut, shape, form, or mold materials such as metal, plastic, rubber, etc. Some examples of tools and dies are punches, dies, molds, jigs, fixtures, etc.

One of the best Tool & Die Steels Supplier in Manesar city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc. Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website:

https://www.viratsteels.com/

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-manesar/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: info@viratsteels.com. Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Tool and Die Steel Supplier in Alwar, Rajasthan

Are you looking for Tool and Die Steel Supplier in Alwar Rajasthan?

Alwar is known for its historical monuments, such as the Alwar Fort, the Bhangarh Fort, and the Sariska Tiger Reserve. Alwar is also an industrial hub, with many manufacturing plants and agricultural products.

Some of the companies that manufacture or supply steel products in Alwar offers industrial MS fabrication, CNC machining, and tool room services. It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.

One of the best Tool & Die Steels Supplier in #Alwar city is:

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA : We deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. We have provide value added services, such as material machining, cut pieces, and tailor-made material. We also offer metallurgical advice and quality assurance.

We have a state-of-the-art plant in #Gurugram and #Ludhiana. We also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-alwar/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: 098140 21775

Are you looking for top-quality tools, die, and mold steel in India?

Look no further! … We offer a wide selection of highest quality steel to meet your needs.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

VIRAT SPECIAL STEEL is leading brand in this segment, established 6 Decades before as an Importer, Exporter, Stockiest, Distributor and Supplier for Tool & Alloy Steels products in India.

We are dealing in a wide range of Tool and Alloy Steels segment products which include Cold Work Tool Steels, Hot Work Tool Steels, Die Block Steels, Alloy Steels, and Plastic Mold Steels. Our company stocks best in class products, which are wear and tear resistant and have dimensional accuracy.

Product List

- HOT WORK STEEL ( HH 370 – 410 BHN ) DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Best quality tool steel, die steel, and mold steel suppliers for engineering work in India!

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry – Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions – In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: – Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry – Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: – Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry – Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: – DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways – They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas – Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

India’s top Largest Supplier, Stockiest, Importer and Exporter of H13 Tool Steel!

VIRAT SPECIAL STEELS Pvt. Ltd. Introduce H-13 material & Modify H13 (DIN 2344 / SKD61/ AISI H13) for the application of drop forgings, Extrusion, Pressure Die Casting etc. H13 steels belong to a family of Hot-Working Steels, a group of steel that is used to cut or shape material at high temperatures. These H-group tool steels were developed for strength and hardness during prolonged exposure to elevated temperatures. These tool steels are low carbon and moderate alloy with significant carbide content resulting in good hot hardness and toughness, coupled with fair wear resistance. The main alloy constituents of H13 are Chromium (4.75 to 5.5%); Molybdenum (1.1 to 1.75%); Vanadium (0.8 to 1.2%); and nominal volume of Nickel (only 0.3%).

While Molybdenum and Vanadium provide strength, the high Chromium content makes H13 resistant to softening when at high temperatures (red hardness). H-13 is also resilient in to shock and abrasion. It is capable of withstanding rapid cooling and not prone to heat checking (cracking because of large changes in temperature).

Ease of fabrication is an important consideration in selection of tool steel and H13 steels score highly on this issue. The primary factors that influence easy fabrication are: good Machinability (H series steels score 70 on the Index where W-class steels are at 100), Grindability, Weldability, Hardenability, and Resistance to Distortion, Safety (cracking resistance) and Decarburizing Tendency. H13 steels are high on all these and can be formed (shaped into tool or mould) by conventional means.

Weldability matters mainly for large tools and is the ability to make, alter and repair a tool by welding without the material cracking. A simplistic explanation of Hardenability is whether hardness is maintained through the depth of the material.

H13 steels are particularly useful where precision is required such as for small and medium sized extrusion dies; and ejector pins, apparatus holders and shrink fit chucks. Also for making inserts, cores, and cavities for die casting dies, die casting shot sleeves, hot forging dies, and plastic mould cavities and parts that require a smooth finish.

A major advantage with H13 steels is that they can be Precision-Cast. Not only are cast tools superior to wrought tools in terms of resistance to thermal checking; but if they can be precision cast to near finished size they save significantly on waste and machining. They also allow for pattern making costs to be spread over a large population of tools.

H13 tool steels are practically equivalent to DIN 1.2344 (Europe) and quite similar to grades AFNOR Z 40 COV 5, UNI KU, JIS SKD61, SS 2242, B.S. BH 13 & ASTM A681.

Virat Special Steels – India’s top Largest Supplier, Stockiest, Dealer, Trader Importer and Exporter of H13 Tool Steel and DB6 Tool Steel.

Learn More:

https://www.viratsteels.com/h13.html

How do you choosing the right steel grade for forging ?

During forging, metal is pressed, pounded, or squeezed under great pressure into high strength elements called forgings.

Preheating the metal to the desired temperature before working it is often (but not always) a part of the method. Forging is a totally different process from casting (or foundry) since the metal used to make forged parts is never melted and poured (as in casting).

The forging process will produce parts that are stronger than those manufactured by the other shaping method. This is often why forgings are nearly always used wherever dependability and human safety are essential. However you will rarely see forgings as they are normally component parts contained within assembled things such as airplanes, cars, tractors, ships, oil drilling instrumentation, engines, missiles and all forms of capital equipment.

Steel is an iron-based alloy with small additions of carbon and other elements that impart improvements in various properties. Steel is among the most useful of metals. It is the metal that has the highest strength per unit cost. There are a wide range of steel compositions as well as a wide range of micro structures that can be produced. These ranges allow a large choice of properties to be achieved within the steel-alloy family.

Properties of Compound Steel:

It contains around 1% to 5% of steel that is consolidated with different components. Diverse combination components have remarkable properties and including these components enhance different qualities.

The normal properties of combination steel are Corrosion Resistance, Machinability, Hardenability and Weldability.

Best Steel for Forging:

In forging maximum used two steel grades i.e. H13 Tool Steel and DB6 Tool Steel. If you are research company that provide you steel for your forging company the you are at right place.

Virat Special Steels – India’s top Largest Supplier, Stockiest, Dealer, Trader Importer and Exporter of H13 Tool Steel and DB6 Tool Steel.

Learn More:

https://www.viratsteels.com/h13.html

https://www.viratsteels.com/db6.html

https://www.db6steel.com/

Any further queries feel free to contact us :

Email us: info@viratsteels.com or Call us now: +91-98140 21775

We Provide our Special Steels in All Cities in #India: