Plastic Mould Steels

now browsing by category

Your Trusted DIN 2738 Steel Supplier of High-quality Steel in India!

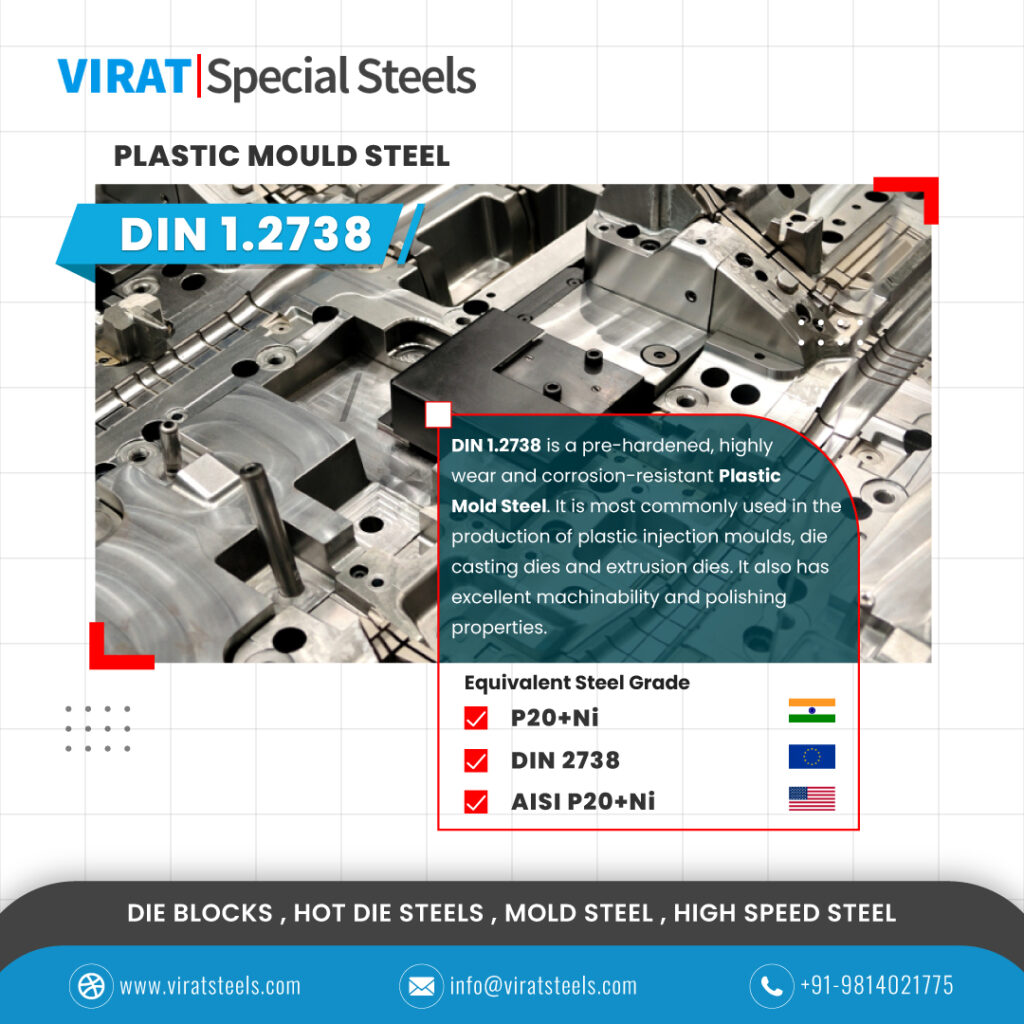

DIN 2738 is a premium mold steel that offers excellent polishability, wear resistance, and toughness, making it ideal for a wide range of tooling applications. DIN 2738 or P20+Ni is a specially designed mold steel with improved toughness and excellent machinability compared to standard P20 grades.

DIN 1.2738 is a widely used cold work steel, especially in the plastic mold industry. It is equivalent to P20+Ni and AISI P20+Ni tool steel. DIN 2738 steels have superior polishability compared to 1.2312 (AISI P20+S) and better machinability. To enhance the hardness and wearability of the mould surface material , it can be treated with nitrogenation and flame hardening. DIN 2738 steel is melted in an electrical furnace and refined using a VOD or DH equipment.

Chemical Composition:

Carbon (C): 0.35-0.45%, Manganese (Mn): 1.30-1.60%, Silicon (Si): 0.20-0.40%, Phosphorus (P): ≤ 0.030%, Sulfur (S): ≤ 0.030%, Chromium (Cr): 1.80-2.10%, Nickel (Ni): 0.90-1.20%, Molybdenum (Mo): 0.15-0.25%

Mechanical Properties:

Tensile Strength: 980-1180 MPa

Yield Strength: ≥ 800 MPa

Elongation: ≥ 15%

Hardness: 280-325 HB

Physical Properties:

Density: DIN 2738 and P20+Ni have a density of approximately 7.85 g/cm³.

Thermal Conductivity: The thermal conductivity of these steels is around 30-35 W/(m·K).

Specific Heat Capacity: The specific heat capacity is about 460-480 J/(kg·K).

Thermal Expansion: The linear coefficient of thermal expansion is approximately 11-12 x 10^-6 /K.

Application:

DIN 2738 is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

At Virat Special Steels, we provide DIN 2738 in round bar and flat bar blocks in different sizes and conditions to meet your specific requirements. Our team of experts is ready to assist you with any queries you have about DIN 2738 steel.

Learn more: https://www.viratsteels.com/din-2738.html

Contact us today to buy the best quality DIN 2738 steel for your tooling needs!

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com/

📬 info@viratsteels.com

Tool and Die Steel Supplier in Faridabad, Haryana!

Are you looking for Tool and Die Steel Supplier in #Faridabad, #Haryana?

Tool and Die Steel Supplier in Faridabad

Faridabad is the most populous city in the Indian state of Haryana and a part of Delhi National Capital Region. It is one of the major satellite cities around Delhi and is located 284 kilometres south of the state capital Chandigarh. The river Yamuna forms the eastern district boundary with Uttar Pradesh. Faridabad was founded in 1607 by Shaikh Farīd, treasurer for the Mughal emperor Jahāngīr, to protect the high road between Delhi and Agra. It is a major industrial hub and a smart city under the Government of India’s flagship Smart Cities Mission.

Faridabad is a city in Haryana, India, that has many steel industries. Some of the companies that manufacture or supply steel products in Faridabad.It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.Tools and die steel industries are companies that manufacture or supply tools and dies for various industrial applications. Tools and dies are specialized devices that are used to cut, shape, form, or mold materials such as metal, plastic, rubber, etc. Some examples of tools and dies are punches, dies, molds, jigs, fixtures, etc.

One of the best Tool & Die Steels Supplier in Faridabad city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India. You can visit their website: https://www.viratsteels.com/

The following grades of steel are available with them on an ex-stock basis:

- 1. DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- 2. HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- 3. PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- 4. HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- 5. COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- 6. ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, Hitachi Steel; Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

Consult our Gurugram office for further assistance.

Meanwhile for more on Virat Special Steels;

Email Us: info@viratsteels.com.

Contact them by mobile numbers 98140 – 21775, 99991 – 24971 to 79.

Tool and Die Steel Supplier in Alwar, Rajasthan

Are you looking for Tool and Die Steel Supplier in Alwar Rajasthan?

Alwar is known for its historical monuments, such as the Alwar Fort, the Bhangarh Fort, and the Sariska Tiger Reserve. Alwar is also an industrial hub, with many manufacturing plants and agricultural products.

Some of the companies that manufacture or supply steel products in Alwar offers industrial MS fabrication, CNC machining, and tool room services. It also has some steel industries that manufacture and supply various steel products, such as tool steel, die steel, alloy steel, mould steels and Alloy Steels, En-Series.

One of the best Tool & Die Steels Supplier in #Alwar city is:

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA : We deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. We have provide value added services, such as material machining, cut pieces, and tailor-made material. We also offer metallurgical advice and quality assurance.

We have a state-of-the-art plant in #Gurugram and #Ludhiana. We also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

- DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-alwar/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: 098140 21775

What are the main challenge does Steel industry is facing now?

The Tool and Die Steel industry faces several common issues that can impact productivity, quality, and overall efficiency. The top five key challenges and potential solutions:

- Material Selection:

😒 Choosing the right tool and die materials for specific applications can be challenging.

👉Solution: Conduct thorough material analysis and consider factors like hardness, toughness, and wear resistance. Collaborate with material experts to make informed decisions. - Tool Wear and Failure:

😒Tools and Dies can experience wear and failure over time, affecting the quality of the produced parts.

👉Solution: Implement a regular maintenance schedule to inspect and replace worn-out parts. Use high-quality tool steels and coatings to enhance durability. - Heat Treatment Issues:

😒Inconsistent heat treatment can lead to variations in hardness and other material properties.

👉 Solution: Develop and adhere to precise heat treatment processes. Monitor and control temperature, quenching, and tempering to ensure consistent results. - Precision and Tolerance Challenges:

😒Achieving tight tolerances and precision in manufacturing can be difficult.

👉Solution: Invest in high-precision machining equipment and regularly calibrate machines. Implement quality control measures such as statistical process control (SPC) to monitor and improve tolerances. - Tool Design Complexity:

😒Complex tool and die designs can lead to increased production time and costs.

👉Solution: Utilize computer-aided design (CAD) software to streamline the design process. Optimize designs for manufacturability to reduce complexity and improve efficiency.

Addressing these common issues requires a holistic approach that combines technological innovation, skilled workforce development, and robust quality control measures.

Virat Special Steels can assess the quality, mechanical properties, structural integrity, and dimensional accuracy of their die blocks. This helps them deliver reliable and high-quality products to their customers, meeting their expectations and ensuring successful forming processes.

Contact Us Today:

Ready to elevate your projects with top-quality die steel?

Contact VIRAT SPECIAL STEELS PVT. LIMITED , INDIA today!

Learn More:

https://www.viratsteels.com/

Are you looking for top-quality tools, die, and mold steel in India?

Look no further! … We offer a wide selection of highest quality steel to meet your needs.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

VIRAT SPECIAL STEEL is leading brand in this segment, established 6 Decades before as an Importer, Exporter, Stockiest, Distributor and Supplier for Tool & Alloy Steels products in India.

We are dealing in a wide range of Tool and Alloy Steels segment products which include Cold Work Tool Steels, Hot Work Tool Steels, Die Block Steels, Alloy Steels, and Plastic Mold Steels. Our company stocks best in class products, which are wear and tear resistant and have dimensional accuracy.

Product List

- HOT WORK STEEL ( HH 370 – 410 BHN ) DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Do you know Steel is 100% recyclable without loss of quality?

Why is steel most recycled? Steel Facts 🤖 by #viratspecialsteels

Steel is a permanent material that can be infinitely recycled and is 100% recyclable without loss of quality. It is a permanent material that can be recycled indefinitely without loss of quality. Steel is one of the most recycled materials in the world and has a high recycling rate due to its unique properties that make it easy to recycle.

The recycling process for steel involves melting down scrap steel in a furnace, purifying it, and then casting it into new products. The resulting product is of the same quality as virgin steel and can be used in a variety of applications, including construction, automotive, and manufacturing industries. Overall, steel is considered to be 100% recyclable, making it a sustainable and environmentally friendly material choice.

VIRAT SPECIAL STEEL is leading brand in this segment, established 6 Decades before as an Importer, Exporter, Stockiest, Distributor and Supplier for Tool & Alloy Steels products in India.

We are dealing in a wide range of Tool and Alloy Steels segment products which include Cold Work Tool Steels, Hot Work Tool Steels, Die Block Steels, Alloy Steels, and Plastic Mold Steels. Our company stocks best in class products, which are wear and tear resistant and have dimensional accuracy.

Product List

- HOT WORK STEEL ( HH 370 – 410 BHN ) (DB6 Steel / DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Size Range in Forged / Rolled Bars

Rounds: 13mm dia to 1500mm Dia

Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Are you looking for PLASTIC MOULD STEEL in India?

Plastic mould steels are widely used for manufacturing mould for plastic.

Get in touch with us today to place your requirement!

DIN 2738 #PlasticMouldSteel, The equivalent grade P20+Ni | DIN 2738 | AISI P20+Ni …

DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making moulds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish.

Also the specialized steels that have been created for plastic moulding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity. DIN 1.2738 Steels are low Carbon consisting of Carbon between 0.35 to 0.45%

Mode of Supply:

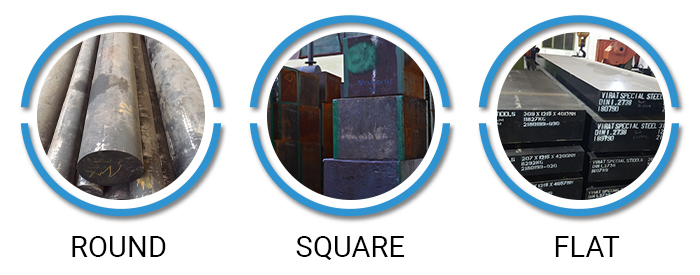

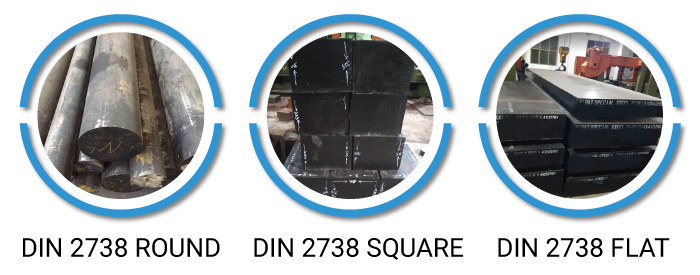

Virat Special Steels is the largest stockiest and supplier of DIN 2738 steel in flat, square and round bar. We provide steel in all sizes as your requirements.

Learn more:

https://www.viratsteels.com/p20ni.html

For more information Contact us:

info@viratsteels.com, +91-9814021775

Looking for the best quality Tool Steel, Die and Mold Steels Supplier for your engineering works!

As one of India’s leading special steel suppliers, #ViratSpecialSteels can supply the following industries requirement of steel practically off-the-shelf.

Virat Special Steels Pvt. Ltd., is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Forging Industry – Forging is a process in which metal is being shaped using compressive forces with a Hammer or a press. Forging are classified into Cold forging, warm forging or hot forging. Mainly material used: Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343(H11).

Pressure Die Casting – Die casting is performed by forcing molten metal under high pressure into a mold cavity & the cavity (mold cavity) is manufacture by using two hardened tool steel dies & perform similar to an injection mold. Mainly material used: Hot die steel i.e. DIN 1.2344(H13), DIN 1.2343(H11), and DIN 1.2581(H21).

Aluminum Extrusions – In Extrusion process material is pushed through a die to the desired cross section & in this manufacturing process it creates very complex cross section. The parts are being formed with an excellent surface finish. Mainly material used: – Hot die steels i.e. DIN 1.2344 (H13) grade.

Automotive Industry – Automotive industry are wide range of companies is mainly involved in manufacturing, design, development, of motor vehicles. Mainly material used: – Din 1.2714(DB6), DIN 40NiCrMo84(EN24), DIN 3343(M2), 16Mncr5, 20Mncr5.

Plastic industry – Polymer materials are manufactures in plastic industry and offers services to aerospace, building, construction, electronics, packaging and transportation. Mainly material used: – DIN 2738 (P20+ Ni), DIN 2311(P20).

Railways – They are involves mainly in manufacturing railways components i.e. Railway gear holder, Railway bogie cast parts, Railways axles, railways Sets of pins, Ground lever frame, adjustable crank, Compressor pistons, Compressor bearings. Mainly material used:-Din 1.2714(DB6), DIN 1.2344(H13), DIN 1.2343 (H11), DIN 40NiCrMo84(EN24), 20NiCrMo5(EN353).

Oil & Gas – Oil & Gas they supply more than 60 percent of our nation’s energy. Natural gas also helps generate the electricity that powers our daily lives.

They also have a fully equipped quality assurance and process examination facility that conducts tests such as hardness and analyses of grain structure.

Find us:

Website: https://www.viratsteels.com/

Email us: info@viratsteels.com

Call Us Now: +91-9814021775

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2015 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stockist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes – Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter – Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

Feel free to contact us :

Corporate Office, #Gurgaon

Administrative Office, #Ludhiana

Email: info@viratsteels.com.

or Call us: 098140 21775

Plastic Mold Steels P20+Ni | DIN 2738 | AISI P20+Ni

DIN 2738 which is applicable for large & small plastic mold dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Up setter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making molds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish. Also the specialized steels that have been created for plastic molding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity.

Steel properties as given below, however, have to be optimally matched to the specific application and these are:

- Degree of purity

- Polishability

- Uniformity of hardness and microstructure

- Wear resistance

- Temperature resistance

- Machinability

- Toughness and hardness

- Thermal conductivity

The Nickel component contributes uniform hardness and structure, improves machinability and a polish that is easy to maintain.

This makes 1.2738 mold steel the ideal material for relatively low temperature applications such as die casting dies and injection molds, synthetic plastic molds dies, and especially for large plastic molds that are easily stressed at their core. They are also ideal for hydroforming tools. DIN 1.2738 is suitable for nitriding and chrome plating.

It is the preferred material for molds shaping plastic products such as automobile bumpers and TV shells. And also for molds for rubber products that are based on both hard rubber (PS) and ultra-hardened rubber (ABS). It is excellent in its processing performance, easy cutting and imparting finish to the end product. It resists electrical corrosion.

It is most cost effective when used for high-volume plastic molding such as TV set bodies, laptop bodies, plastic parts for home appliances and automotive parts and any such where finish is important.

As Virat Special Steels inform us, DIN 1.2738 tool steel is usually supplied as pre-hardened/quenched and tempered to 280 – 320 HB hardness. Still, after machining if the need arises, they can be annealed by first heating to 710°C and after the temperature gap between core and surface has narrowed to 740 °C for about 2 to 5 hours; followed by cooling slowly at the rate of 10 to 20 °C per hour to about 600 °C before further air cooling.

Hardening is conducted in the temperature range of 840-870°C to be followed by immediate quenching in oil/hot bath/air to a temperature between 180 to 220°C. Hardness after quenching is around 52 HRC.

Two rounds of tempering are required immediately after such hardening and the heating to tempering temperature must be gradual. Higher temperatures result in steel with lower hardness values (700°C results in an HRc of barely 30 while tempering at 250°C will result in HRc of 50). The duration of tempering at the chosen temperature should correspond to 1 hour per 20 mm of thickness.

They are usually supplied as Round Bar of diameter ranging from 20mm to 1000mm or as Plate or Block of thickness ranging from 12-500mm x width 200-2000mm. Generally black on the surface, they can be customized for clients in Roughly Machined, Peeled or Turned condition.

The Leading Company VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stuckist of P20+Ni | DIN 2738 | AISI P20+Ni

Learn more:

https://www.viratsteels.com/p20ni.html

For more information Contact us:

info@viratsteels.com, +91-9814021775