Tool Steel

now browsing by category

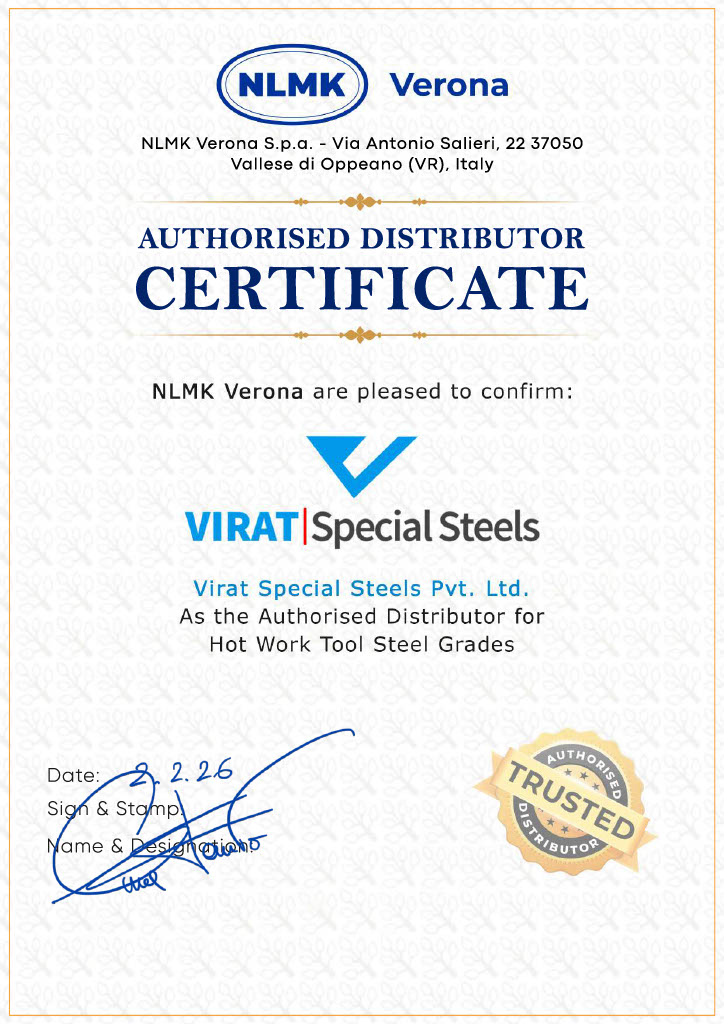

Virat Special Steels Recognized as Authorised Distributor by NLMK Verona

[Strengthening India’s Access to Genuine European Tool Steel]

Virat Special Steels Pvt. Ltd. is proud to announce a significant milestone in our journey—official recognition as the Authorised Distributor for Hot Work Tool Steel Grades by NLMK Verona S.p.a., Italy. This milestone, dated 2nd February 2026, marks a new chapter in our commitment to delivering excellence in the steel industry.

Virat Special Steels Pvt. Ltd. has been recognized as one of the largest Importers, Exporters, and Stockists of premium steel products of :

- Die Blocks (DIN 1.2714, DB6, H13, H11)

- Tool Steels & Die Steels

- Special Steels & Alloy Steels in multiple grades

Backed by decades of expertise, the company maintains the largest steel yards, ensuring consistent availability, unmatched quality, and timely delivery to domestic industries.

NLMK Verona, a renowned name in the global steel sector, has entrusted Virat Special Steels with the responsibility of distributing their Hot Work Tool Steel Grades in India. This partnership reflects not only our technical expertise but also the trust we have built over the years with our customers and partners.

What This Means for Our Customers

Being an Authorised & Trusted Distributor ensures that our customers benefit from:

- Authentic NLMK Verona products with guaranteed quality

- Reliable supply chain solutions met to industry needs

- Global standards of excellence delivered locally

- On-ground technical support and grade selection support

Whether you are manufacturing dies, Molds, or critical tooling components, Virat Steels ensures your tools are built on proven European steel excellence drive productivity.

Looking Ahead

This achievement is not just a certificate— It’s a promise of authentic material, consistent quality, and strong technical partnership for the Indian tooling industry.

European tool steel excellence is now officially within reach.

Connect with Virat Special Steels to explore NLMK Verona’s authorised tool and die steel range and elevate your tooling performance.

Web: www.viratsteels.com

Email Us: info@viratsteels.com.

Ph: 98140-21775, 9999124971-80 , 9216321771-79.

Virat Special Steels an ISO 9001:2015 Certified Trading Company

Elevating Standards as an ISO 9001:2015 Certified Trading Company

Introduction: A Legacy of Excellence

Virat Special Steels is a name synonymous with trust, quality, and innovation in the steel trading industry. As an ISO 9001:2015 certified trading company, we are committed to setting benchmarks in quality and operational efficiency. Our dedication to upgrading infrastructure and maintaining world-class standards makes us the go-to partner for high-quality steel solutions. Whether you are constructing skyscrapers or manufacturing precision tools, Virat Special Steels ensures you get the finest products with expert guidance every step of the way.

What Makes ISO 9001:20215 Certification Significant?

Understanding ISO 9001:2015

ISO 9001:2015 certification is a globally recognized standard for quality management systems. It emphasizes:

- Meeting customer needs consistently.

- Adopting a process-driven approach for efficiency.

- Continuously improving systems for enhanced outcomes.

Virat Special Steels’ Certification

Being certified under ISO 9001:2015 highlights our commitment to:

- Ensuring superior quality standards.

- Streamlining processes to reduce delays.

- Delivering unparalleled customer satisfaction.

This certification reflects our dedication to staying ahead in the competitive steel trading market.

Our Commitment to Quality and Continuous Improvement

At Virat Special Steels, improvement isn’t a one-time effort—it’s a way of life. Our approach is grounded in:

- Upgrading Technology: Regular investments in cutting-edge machinery and tools ensure optimal efficiency and accuracy.

- Employee Training: Skilled professionals are empowered with continuous learning to excel in their roles.

- Customer-Centric Approach: Every product and service is designed with customer satisfaction in mind.

World-Class Infrastructure: Where Innovation Meets Precision

To deliver top-notch steel products, a robust infrastructure is essential. Virat Special Steels takes pride in its state-of-the-art facilities, designed for precision, speed, and reliability.

Machinery and Equipment

Our infrastructure is equipped with the latest tools and technologies, ensuring seamless operations:

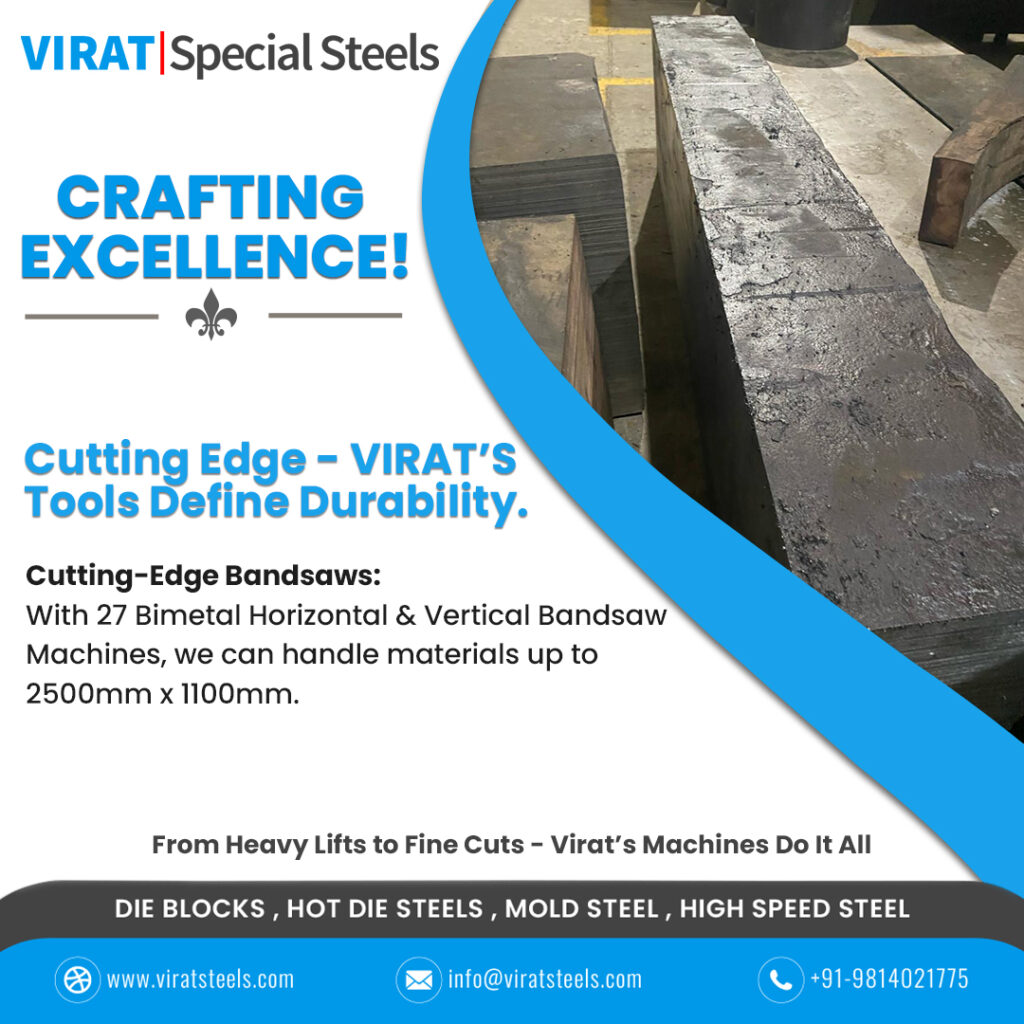

- 27 Bimetal Horizontal & Vertical Bandsaw Machines: Cutting capacity up to 2500mm x 1100mm, catering to projects of any scale.

- 14 Overhead Lifting Cranes: Lifting capacity of up to 20 tons for effortless material handling.

- 20 Lifting Magnets: Each with a lifting capacity of up to 5 tons, ensuring safety and efficiency.

- 2 Fork Lifters: Designed to handle up to 3 tons, streamlining transportation within the plant.

Advanced Testing Facilities

Quality assurance is integral to our operations. Our in-house testing facilities include:

- Chemical & Spectro Lab: Ensures the composition meets industry standards.

- UT Testing Machine: Non-destructive testing for structural integrity.

- Hardness Tester: Measures the durability of our steel products, ensuring they stand the test of time.

Machining Plant

Our machining plant ensures precise customization to meet diverse project requirements, delivering products tailored to perfection.

Why Choose Virat Special Steels?

1. Superior Product Quality

Every product from Virat Special Steels meets rigorous quality checks. From raw materials to finished goods, quality is our top priority.

2. Expert Guidance

Our experienced team provides technical advice, ensuring you select the right product for your project. Whether it’s construction, machinery, or industrial manufacturing, our experts have you covered.

3. Comprehensive Range of Products

We offer a wide array of steel products, catering to diverse industries. Our inventory ensures you get exactly what you need, when you need it.

4. Commitment to Sustainability

Sustainability is at the heart of our operations. By using energy-efficient processes and reducing waste, we contribute to a greener planet.

Applications of Virat Special Steels’ Products

Virat Special Steels caters to a wide range of industries, ensuring our steel solutions meet specific needs:

- Construction: Reinforcing bars, structural steel, and beams for high-rise buildings and infrastructure.

- Automotive: High-grade steel for vehicle components, ensuring safety and durability.

- Industrial Machinery: Precision steel products for equipment that drives industrial growth.

- Tool Manufacturing: Specialized steel grades for making cutting tools and molds.

Dedicated to Customer Satisfaction

At Virat Special Steels, our customers are at the core of our mission. Here’s how we ensure satisfaction:

- Timely Deliveries: Robust logistics systems ensure products reach you on time, every time.

- Customization Options: Tailored solutions for unique project requirements.

- Reliable Support: A dedicated team to resolve queries and provide seamless after-sales service.

Looking Ahead: The Future of Virat Special Steels

As a forward-thinking company, Virat Special Steels is constantly innovating. Our goals for the future include:

- Expanding our product portfolio to cater to emerging markets.

- Investing in advanced automation for faster and more precise manufacturing.

- Strengthening our sustainability practices to contribute to a better tomorrow.

Conclusion: Building the Future with Virat Special Steels

When it comes to premium steel solutions, Virat Special Steels stands unmatched. With ISO 9001:2015 certification, cutting-edge infrastructure, and a commitment to excellence, we empower industries to achieve their goals. Trust Virat Special Steels for unmatched quality, expert guidance, and a partner dedicated to your success.

FAQs

1. What does ISO 9001:2015 certification mean for customers?

It ensures that customers receive products and services of the highest quality, backed by reliable processes and consistent improvements.

2. What industries does Virat Special Steels serve?

We serve industries such as forging, automotive, industrial machinery, and tool manufacturing.

3. What testing facilities are available at Virat Special Steels?

Our facilities include a chemical and spectro lab, UT testing machine, hardness tester, and more for comprehensive quality assurance.

4. Can I get customized steel products from Virat Special Steels?

Absolutely! We offer customized solutions to meet unique project needs.

5. How does Virat Special Steels ensure sustainability?

By adopting energy-efficient processes, minimizing waste, and prioritizing eco-friendly practices, we contribute to sustainable development.

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA!

https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business!

https://www.viratsteel.in/special-steel-supply-networks/

Watch now:

https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎+91 98140-21775

High-Speed Steel vs High Carbon Steel

Steel is a cornerstone of modern industries, from construction to manufacturing. Two of the most widely used types of steel are high-speed steel (HSS) and high-carbon steel. But which one suits your needs better? This article dives deep into their properties, applications, and advantages to help you make an informed decision.

Understanding High-Speed Steel (HSS)

Composition of High-Speed Steel- High-speed steel is a specialized alloy known for its ability to withstand high temperatures and maintain its hardness. The key components include:

- Carbon: Provides hardness and strength.

- Tungsten or Molybdenum: Enhances heat resistance.

- Chromium and Vanadium: Improve wear resistance and toughness.

This unique combination allows HSS to perform exceptionally well in demanding conditions, especially in machining and cutting applications.

Properties of High-Speed Steel- High-speed steel stands out due to its remarkable properties:

- Heat Resistance: Withstands temperatures up to 600°C without losing hardness.

- Durability: Resistant to wear and tear, making it ideal for heavy-duty applications.

- High Hardness Levels: Maintains a sharp edge even after prolonged use.

These properties make HSS a go-to material for high-performance tools and components.

Applications of High-Speed Steel- High-speed steel is indispensable in industries requiring precision and durability. Its common applications include:

- Cutting Tools: Drills, milling cutters, and taps.

- Machinery Components: Gears and other machine parts exposed to high stress.

- Industrial Manufacturing: Ideal for machining operations that require sustained performance under extreme conditions.

Exploring High Carbon Steel

Composition of High Carbon Steel– High-carbon steel contains a significant amount of carbon, usually between 0.6% and 1.4%. This high carbon content gives it:

- Enhanced Hardness: Perfect for applications requiring extreme strength.

- Reduced Malleability: Results in increased brittleness.

Properties of High Carbon Steel– High-carbon steel is prized for its unique attributes:

- Strength and Toughness: Ideal for tools that endure significant mechanical stress.

- Wear Resistance: Lasts longer in abrasive environments.

- Brittleness: While strong, it is prone to cracking under impact if not treated carefully.

Applications of High Carbon Steel– High-carbon steel finds use in areas where strength and sharpness are critical:

- Blades and Cutting Edges: Knives, swords, and industrial cutting tools.

- Springs: Automotive and industrial springs.

- Structural Components: Ideal for load-bearing parts in construction and manufacturing.

Key Differences Between High-Speed Steel and High Carbon Steel

Mechanical Properties

- HSS: Superior hardness and heat resistance make it perfect for high-speed operations.

- High Carbon Steel: Higher tensile strength but limited heat tolerance compared to HSS.

Thermal Properties

- HSS: Can withstand higher temperatures without losing performance.

- High Carbon Steel: Loses effectiveness when exposed to extreme heat for prolonged periods.

Cost and Availability

- HSS: More expensive due to its complex alloying process and superior properties.

- High Carbon Steel: More affordable and widely available, but with limited applications in high-temperature environments.

Advantages and Disadvantages

Pros and Cons of High-Speed Steel

Pros:

- Exceptional heat resistance

- High durability and wear resistance

- Ideal for precision tools

Cons:

- Higher cost

- Challenging to machine or shape

Pros and Cons of High Carbon Steel

Pros:

- Affordable and readily available

- High strength and sharpness

- Excellent for low-heat applications

Cons:

- Brittle and prone to cracking

- Limited heat resistance

Choosing the Right Steel for Your Application

Key Factors to Consider

When selecting between HSS and high-carbon steel, consider:

- Application Requirements: Tools or components exposed to high temperatures? Opt for HSS.

- Budget: High-carbon steel offers a cost-effective solution for less demanding applications.

- Durability Needs: For longer-lasting performance, HSS is a better choice.

Industry Insights

Experts at Virat Special Steels recommend HSS for industries like machining and high-carbon steel for tools requiring sharp edges. HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35), HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

Innovations in Steel Technology

Steel technology is constantly evolving. Virat Special Steels stays at the forefront by investing in research and development to deliver cutting-edge solutions for both high-speed and high-carbon steel.

Conclusion:

Choosing between high-speed steel and high-carbon steel depends on your specific requirements. High-speed steel is unbeatable in high-temperature and high-performance applications, while high-carbon steel is a cost-effective choice for simpler tasks. For top-quality steel products, trust Virat Special Steels, where innovation meets reliability.

FAQs

- What is the main difference between high-speed steel and high-carbon steel?

High-speed steel excels in heat resistance and durability, while high-carbon steel offers superior strength and sharpness for low-heat applications. - Which steel is better for cutting tools?

High-speed steel is ideal for cutting tools due to its ability to maintain hardness at high temperatures. - How does the cost of high-speed steel compare to high-carbon steel?

High-speed steel is more expensive due to its advanced properties, while high-carbon steel is more budget-friendly. - Can high-carbon steel be heat-treated for better performance?

Yes, heat treatment can enhance the strength and durability of high-carbon steel. - Why should I choose Virat Special Steels for my steel needs?

Virat Special Steels offers premium-quality products, expert guidance, and innovative solutions tailored to your requirements.

Crafting Excellence with Virat Special Steels

When it comes to strength, durability, and unparalleled precision, Virat Special Steels stands tall as an industry leader. Combining state-of-the-art technology, innovative craftsmanship, and an unwavering commitment to quality, Virat redefines steel processing. From cutting-edge bandsaw machines to maintaining the largest steel yards stocked with premium grades of special steels, Virat ensures every customer gets nothing short of excellence.

Let’s dive deeper into why Virat Special Steels is your ultimate partner for steel processing needs.

Introduction to Virat Special Steels

Virat Special Steels has cemented its place as a trusted name in steel processing. With decades of experience and an unwavering commitment to innovation, the company continues to set benchmarks in the industry. Whether it’s about delivering high-grade steel or ensuring cutting precision with bandsaw technology, Virat is synonymous with reliability and performance.

Unmatched Durability and Precision

At Virat, durability isn’t just a promise; it’s a standard. Every product and service offered by the company is tailored to meet the most rigorous demands. Whether you’re working on massive industrial projects or intricate designs, Virat ensures strength and precision every step of the way.

Their motto? “When it’s about durability, strength, and precision – it’s Virat!“

Cutting-Edge Bandsaw Technology:

Features of Virat’s Bandsaw Machines: Virat Special Steels takes pride in its 27 state-of-the-art bi-metal horizontal and vertical bandsaw machines. These machines are equipped with advanced features to ensure:

- Exceptional Cutting Precision: Cut through a wide variety of materials with unparalleled accuracy.

- Impressive Material Handling Capacity: Able to handle dimensions as large as 2500 mm x 1100 mm.

- Efficiency and Speed: Delivering quick results without compromising quality.

- Versatility: Perfect for various industrial applications.

Handling Large-Scale Materials with Ease

Large-scale industrial projects demand equipment that can handle significant workloads. Virat’s bandsaws rise to the challenge by ensuring efficient cutting of oversized materials, reducing lead times, and enhancing productivity.

Why Choose Virat Special Steels?

Expertise in Steel Processing: With a team of skilled professionals and decades of experience, Virat is equipped to handle complex steel processing projects with ease.

Focus on Quality and Innovation

The company’s commitment to quality and innovation is evident in its use of cutting-edge technology and its dedication to customer satisfaction.

- What makes Virat’s bandsaw machines stand out?

Virat’s bandsaw machines are equipped with advanced technology that ensures precision, speed, and efficiency. They can handle large materials and deliver unmatched results. - What types of steels does Virat offer?

Virat specializes in tool steels, die steels, alloy steels, and other special grades like DIN 2714, DB6, H13, and H11. - How large are the materials Virat can process?

Virat’s bandsaw machines can handle materials as large as 2500 mm x 1100 mm, making them suitable for heavy-duty industrial projects. - Why should I choose Virat for my steel processing needs?

Virat offers a combination of cutting-edge technology, high-quality materials, and exceptional expertise, ensuring precision and durability in every project. - How can I get in touch with Virat Special Steels?

You can contact Virat through their official website (www.viratsteels.com) or reach out to their team directly to discuss your requirements and place an order.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels like … DIN 2714, DB6, H13, H11, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteel.in/special-steel-supply-networks/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91-9814021775

Exploring the Versatility of M2 High-Speed Tool Steel Powerhouse!

Discover the power of M2 Steel the high-speed tool steel that belongs to the tungsten–molybdenum series for cutting tools industries. Let’s delve into the details of M2 Steel, also known as AISI M2 or DIN 1.3343, particularly as offered by Virat Special Steels.

In the world of manufacturing and metalworking, the quest for materials that can withstand the rigors of high-speed operations is relentless. Enter M2 Steel, a high-speed tool steel that is part of the tungsten-molybdenum series, renowned for its exceptional performance in cutting tool industries. This steel grade, also known as DIN 1.3343 or AISI M2, is offered by Virat Special Steels, a name synonymous with quality and reliability in the steel industry.

M2 Steel stands out for its well-balanced composition, which provides a harmonious blend of toughness, wear resistance, and red hardness. These properties make it an ideal choice for a wide range of applications, from twist drills and milling cutters to broaches and reamers. The steel’s ability to retain a sharp cutting edge even at elevated temperatures is a testament to its superior quality.

The chemical makeup of M2 Steel includes a rich mix of molybdenum, tungsten, and vanadium, alongside a carbon content that exceeds 0.60%. This unique alloying allows M2 Steel to cut through metals at high speeds, significantly reducing material removal time and enhancing production efficiency.

One of the key advantages of M2 Steel is its versatility. It is frequently used in cold work punches, dies, and high-speed, light-cutting applications. Its popularity stems from its ability to replace the older T1 high-speed steel in most applications due to its superior properties and cost-effectiveness.

Virat Special Steels takes pride in being the leading supplier and stockiest of DIN 1.3343 in Europe. Their commitment to quality ensures that the M2 Steel they offer has undergone rigorous testing and meets the highest standards of toughness and cutting edge retention. This makes it suitable for a large variety of applications, especially in the cutting tools industry where precision and durability are paramount.

In conclusion, M2 Steel is more than just a material; it’s a cornerstone of high-speed tool steel that empowers industries to push the boundaries of production. Its exceptional properties and the assurance of quality from suppliers like Virat Special Steels make it a go-to choice for those looking to ‘heat up their production’ and achieve excellence in their manufacturing processes. For more information on M2 Steel and its applications, or to consult with an expert, consider visiting the Espresso Drive Cafe in Gurugram, where the fusion of steel and strategy brews over a cup of coffee.

Contact us today to learn more about our products and services!

🌐https://www.viratsteels.com/m2.html

📬info@viratsteels.com ☎+91 98140-21775

Know more about H13 Tool Steel Supplier in India?

Virat Special Steels is the world largest Supplier, Stockiest, Importer and Exporter of H13 Hot Die Block or Hot Work Steel.

H13 has worthy thermal shock resistance and can endure some water freezing in service. Nitriding will improve rigidity. H13 has bigger similarity and an exceptionally fine structure, leading to improved machinability, polishability and high-temperature tensile strength.

About us– With the opening up of the global markets, VIRAT STEELS started importing Tools & Die Steels from the world’s top most manufacturing companies like. M/s Vitkovice , Czech Republic, Deutche Edelstahlwerke from Germany, Somers Forge from England. who recognized trade house. The state of art machines and required infrastructure are being installed at the steel yard at its head office and branches.

H13 tool steel is a versatile chromium-molybdenum hot work steel that’s wide utilized in hot work and cold work tooling applications. the recent hardness (hot strength) of H13 resists thermal fatigue cracking that happens as the results of cyclic heating and cooling cycles in hot work tooling applications.

Due to its wonderful combination of high toughness and resistance to thermal fatigue cracking (also called heat checking) H13 is used for additional hot work tooling applications than the other tool steel.

Because of its high toughness and really sensible stability in heat treatment, H13 Tool Steel is additionally utilized in a spread of cold work tooling applications. In these applications, H13 provides higher hardenability (through hardening in giant section thicknesses) and higher wear resistance than common alloy steels like 4140.

APPLICATIONS: – Inserts, cores, and cavities for die casting dies, die casting shot sleeves, hot forging dies, extrusion dies, and plastic mould cavities and parts that need high toughness and wonderful polishability.

Supplier of H13 Steel– Virat Special Steels Pvt Ltd is the world largest H13 Die steel supplier and stockist that supplies H13 steel to all over the world.

Consult our team at Virat Special Steels, will assist you with any queries you have about H13 Steel. Whether you need flat, square, or round bar shapes, we have the right solution for your needs.

Learn more: https://www.viratsteels.com/h13.html

Contact us today to learn more about our products and services!

📬info@viratsteels.com ☎+91 98140-21775

Specialty Tool Steels from Virat Special Steels India!

Tools steels which is also known as Die Steel / Special steel / Mould steel / Edelstahl is a sub matrix that includes alloys developed with the objective of achieving high level of toughness, wear resistance and heat tolerance. These three attributes define the demands of tooling applications and need to be balanced as per usage orientation in different enterprising ambiences. A tool is in constant motion against a substrate that is being processed through it. This necessarily involves the ‘impact’ dimension and it means the factors of wear and heat generation would be prominent. Toughness and strength are the other challenging dimensions that are sought as per requirement of tooling application. While wear resistance as an attribute is directly determined by toughness, heat tolerance is gained by manipulating the thermal conductivity and expansion coefficient of the tool steel.

Virat Special Steels is a leading manufacturer, stockiest and exporter of different tool steel grades and caters to enterprising clients through customized products that are finely suited to demands. To know more about tool steels, please visit our website http://toolsteels.in

Achieving toughness & wear resistance in tool steels / Edelstahl

Higher the toughness of steel, lesser would be wear that is generally exhibited through the undesired chipping, surface abrasion and even breakage during operation. While basic steel is one of the toughest materials, its strength is compromised through addition of specific elements during alloying. These elements include Chromium, Tungsten, Molybdenum and Vanadium and one or more of these are added to generate the wear resistance of the tool steel. The dimensions of toughness and wear resistance are thus balanced in any tool steel through addition of the above stated elements that have abilities to form carbides.

Apart from the alloying composition, the method of production and the subsequent heat treatments are important also for determining the toughness, strength and other characteristics. Tempering and annealing are the two methods that can be carried at desirable temperatures and for specific durations to achieve the demanded features.

Virat Special Steels offers specialized grades in the segments of hot worked, high speed, shock resisting and special purpose tool steels. Here is the selection of tool steels that are manufactured by Virat Steels –

H types – hot work tools steels ( 2714, Db6 steel, H11 steel , h13 steel, 2343 steel, 2344 steel )

D types – high Carbon, High Chromium cold work tool steels ( d3 steel, D2 steel, 2379 steel, 2080 steel )

T types – high speeds (Tungsten base) ( M35 steel )

M types – high speed (Molybdenum base) ( M2 steel )

S types – shock resistant tool steels

W types – water hardened tool steels

O types – oil hardened, cold work tool steel

A types – air hardened, cold work tool steels

P types – plastic moulds ( p20 steel , 2738 steel, 2311 steel )

Special purpose tool steels – L & F (low alloy & Carbon Tungsten types respectively)

Our customer’s supporting website www.viratsteels.com will provide the detailed information.

DIN 3343 or M2 High Speed Steel for your engineering work!

DIN 3343 refers to a German standard for high-speed steel (HSS). It specifies the requirements for HSS materials used in cutting tools, drills, and other applications where high wear resistance and toughness are essential.

The designation DIN 3343 typically corresponds to a specific grade of HSS, which may include elements like tungsten (W), molybdenum (Mo), vanadium (V), and cobalt (Co) to enhance its properties.

These HSS materials are known for their ability to withstand high temperatures during cutting and machining processes. They maintain their hardness even at elevated temperatures, making them suitable for demanding applications.

Equivalent Grades:

M2/DIN 3343/AISI M2/X100CRMOV5

Let’s explore the significant features of DIN 3343 (also known as M2 Steel), which plays a crucial role in the world of tool steels:

- Exceptional Hardness and Wear Resistance: M2 Steel stands as a pinnacle in the realm of high-speed tool steels. Its unmatched hardness and wear resistance make it ideal for cutting, machining, and forming applications. When precision and longevity matter, M2 Steel delivers.

- Heat Resistance: In demanding environments where tools are exposed to high temperatures during cutting and shaping processes, M2 Steel maintains its mechanical properties. It can withstand the heat generated during operations, ensuring consistent performance.

- Toughness and Thermo-Plasticity: The combination of toughness and thermo-plasticity sets M2 Steel apart. Its bending strength and toughness are 50% greater than that of T1 steel, making it a preferred choice in various applications.

- Versatility: Whether it’s cold work punches, dies, or high-speed, light-cutting tools, M2 High-Speed Steel shines. Its adaptability across industries—such as aerospace, automotive, and precision engineering—makes it indispensable.

Remember, proper heat treatment and maintenance are essential to maximize the benefits of M2 Steel. If you’re looking for a reliable supplier, consider exploring Virat Special Steels’ offerings Now.

We supply steel bars to forging companies across #Ludhiana, #Faridabad, #Bhiwadi, #Sonipat, #Rohtak, #Haryana, #Punjab, #Jamshedpur, #Trichy, #Aurangabad, #Pune, #Gurgaon, #Noida, #Ghaziabad, #Indore, and all locations in India. https://www.viratsteel.in/materials/high-speed-steel-supplier-in-india/

Virat Special Steels being a trusted supplier in India, it’s worth exploring their offerings for both DIN 3343 and M2 Steel. Choose Virat Special Steels for your steel needs and experience the difference quality makes.

Contact us today to learn more about our products and services!

🌐https://www.viratsteels.com 📬info@viratsteels.com ☎+91 098140-21775

Explore the beauty of H11 Steel, Properties and Applications!

What is H11 Die steel?

What are the properties and applications of steel?

H11 is a type of hot work tool steel, which is a category of tool steels used in applications where the material is subjected to high temperatures during use, such as in forging or extrusion processes.

H11 die steel is known for its excellent resistance to thermal fatigue, which is the type of fatigue that occurs when a material is subjected to fluctuating or cyclic thermal stresses. This makes it well-suited for use in hot work applications where the tooling is exposed to high temperatures and rapid cooling.

Additionally, H11 die steel has good toughness and wear resistance, further enhancing its suitability for use in demanding hot work environments. It is commonly used in the production of die casting dies, extrusion dies, and other hot work tooling applications.

Properties of H11 steel:

- High Temperature Strength: H11 steel exhibits high strength and hardness at elevated temperatures, making it ideal for use in applications where the material is subjected to high temperatures during operation, such as in forging and extrusion dies.

- Good Toughness: H11 steel has good toughness, which helps prevent the material from cracking or fracturing under high-stress conditions. This property is particularly important in applications where the tooling is subjected to repeated thermal cycling.

- Excellent Wear Resistance: H11 steel offers excellent wear resistance, which helps extend the life of the tooling in applications where it comes into contact with abrasive materials.

- Good Thermal Conductivity: H11 steel has good thermal conductivity, which helps dissipate heat away from the cutting or forming surface, reducing the risk of thermal damage to the tooling.

- Machinability: H11 steel is relatively easy to machine, which can be advantageous in applications where the tooling needs to be machined to precise dimensions.

Applications of H11 steel include:

- Die Casting Dies: H11 steel is commonly used in the production of die casting dies, which are used to manufacture metal parts by forcing molten metal into a mold cavity under high pressure.

- Extrusion Dies: H11 steel is also used in extrusion dies, which are used to shape metal or plastic materials by forcing them through a die under high pressure.

- Forging Dies: H11 steel is used in forging dies, which are used to shape metal parts by hammering or pressing them into shape.

- Hot Shear Blades: H11 steel is used in the production of hot shear blades, which are used to cut hot metal during the forging process.

Overall, H11 steel is a versatile and reliable material that offers a combination of high temperature strength, toughness, and wear resistance, making it well-suited for use in a variety of hot work applications.

Mode of Supply

Virat Special Steels is the largest stockiest and supplier of H11 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H11 die steel is available in flat, square and round shape. Consult our team who will assist you for h11 steel query.

Learn more:

https://www.viratsteels.com/h11.html

Any further queries feel free to contact us :

🌐www.viratsteel.in 📞 +91-98140 21775 📧 info@viratsteels.com

Exploring Tool and Die Steel Supplier in Faridabad?

When it comes to tool and die steel suppliers in Faridabad, there are several options to explore. Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Faridabad!

Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made solutions. With state-of-the-art plants in #Gurugram and #Ludhiana, they have established a strong distribution network across India.

Available Grades:

- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

Quality Assurance and Examination:

Virat Special Steels has an impressive quality assurance facility, including chemical tests, spectrometry, ultrasonic examinations, and hardness testing. This ensures optimal steel selection for specific applications and cost optimization in the long run.

Make In INDIA:

They offer competitive prices, top-notch quality, and prompt service, positioning themselves as a reliable “Make In INDIA” choice for their customers.

For more information, you can explore their details:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-Faridabad/

Remember to explore this suppliers and find the right fit for your specific tool and die steel requirements in Faridabad!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📧 info@viratsteels.com 📞 +91-98140 21775