Uncategorized

now browsing by category

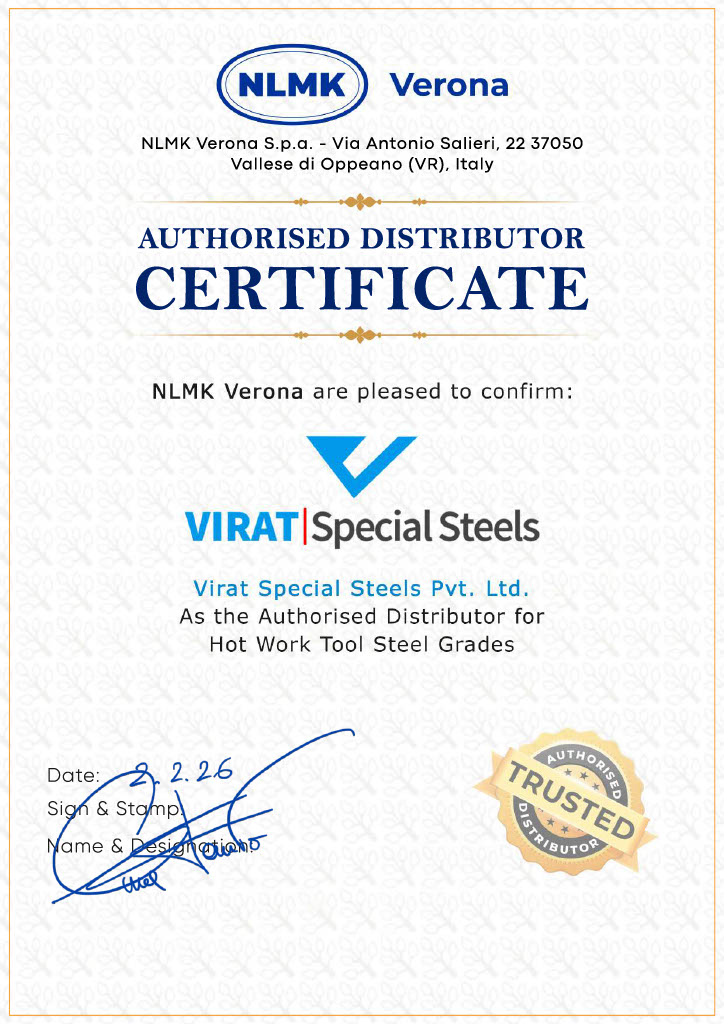

Virat Special Steels Recognized as Authorised Distributor by NLMK Verona

[Strengthening India’s Access to Genuine European Tool Steel]

Virat Special Steels Pvt. Ltd. is proud to announce a significant milestone in our journey—official recognition as the Authorised Distributor for Hot Work Tool Steel Grades by NLMK Verona S.p.a., Italy. This milestone, dated 2nd February 2026, marks a new chapter in our commitment to delivering excellence in the steel industry.

Virat Special Steels Pvt. Ltd. has been recognized as one of the largest Importers, Exporters, and Stockists of premium steel products of :

- Die Blocks (DIN 1.2714, DB6, H13, H11)

- Tool Steels & Die Steels

- Special Steels & Alloy Steels in multiple grades

Backed by decades of expertise, the company maintains the largest steel yards, ensuring consistent availability, unmatched quality, and timely delivery to domestic industries.

NLMK Verona, a renowned name in the global steel sector, has entrusted Virat Special Steels with the responsibility of distributing their Hot Work Tool Steel Grades in India. This partnership reflects not only our technical expertise but also the trust we have built over the years with our customers and partners.

What This Means for Our Customers

Being an Authorised & Trusted Distributor ensures that our customers benefit from:

- Authentic NLMK Verona products with guaranteed quality

- Reliable supply chain solutions met to industry needs

- Global standards of excellence delivered locally

- On-ground technical support and grade selection support

Whether you are manufacturing dies, Molds, or critical tooling components, Virat Steels ensures your tools are built on proven European steel excellence drive productivity.

Looking Ahead

This achievement is not just a certificate— It’s a promise of authentic material, consistent quality, and strong technical partnership for the Indian tooling industry.

European tool steel excellence is now officially within reach.

Connect with Virat Special Steels to explore NLMK Verona’s authorised tool and die steel range and elevate your tooling performance.

Web: www.viratsteels.com

Email Us: info@viratsteels.com.

Ph: 98140-21775, 9999124971-80 , 9216321771-79.

NLMK Verona Tool Steel: Tough & Stable

When it comes to tool steel suppliers in India, industries demand materials of high strength, precision, and durability. Virat Steels having great experience consistently in metal domain for 7 decades bringing you the finest in European engineering—NLMK Verona Tool Steel. Known worldwide for its toughness, stability, and performance, this steel is trusted across sectors where reliability is non-negotiable.

What Makes NLMK Verona Tool Steel Exceptional?

NLMK Verona, part of the globally respected NLMK Group, is a leader in European tool steel manufacturing. Their products are engineered to hold extreme industrial conditions, ensuring longer service life and superior efficiency.

- Unmatched Toughness

- Dimensional Stability

- High Performance

Optimized for demanding applications like die-making, forging, and cutting tools.

Applications Across Industries

NLMK Verona’s tool steels are trusted in sectors where precision and durability are non-negotiable:

- Automotive Manufacturing: For molds, dies, and wear-resistant components.

- Aerospace Engineering: Ensuring stability in parts exposed to extreme conditions.

- Heavy Engineering: Industrial machinery, specialized tools.

- General Manufacturing: From injection Molds to stamping dies, performance is guaranteed.

Virat Steels: Your Trusted Tool Steel Supplier in India

Virat Steels don’t just supply steel—We deliver solutions engineered for success. By offering NLMK Verona European Tool Steel, we empower our clients with materials that defines with excellent cutting-edge metallurgy technology.

When you choose Virat Steels, you are choosing:

- Global quality with local expertise

- Quick Service

- Technical guidance to your needs

NLMK Verona’s European Tool Steel is more than just a material—it’s truly a commitment to performance. At Virat Steels, we are proud to bring this world-class steel to industries across India, ensuring that our customers stay ahead in quality and productivity.

Looking for the best tool steel suppliers in India?

Choose Virat Steels—your gateway to Italian Tool steel excellence & Discover authentic European quality with full assurance.

Meanwhile for more details explore on- https://www.viratsteels.com/

Email Us: info@viratsteels.com.

Ph: 98140 – 21775, 99991 – 24971 to 80 , 92163-21771 to 79.

European Die Steels for Longer Tool Life – Backed by NLMK Verona (Italy) & Virat Steels (India)

When it comes to tool and die steel, what it truly matters is –tool life, that truly considered as an important technical parameter for improved productivity. This is where European Tool & Die Steel continues to stand out as a proven solution.

Why European Tool Steel Stands Apart?

Globally, European tool steels are recognized for :

- Their advanced steel making technology,

- Strict quality control,

- Consistent performance.

NLMK Verona – European Excellence from Italy

NLMK Verona, based in Verona, Italy—an industrial hub known for metallurgical excellence—is a reputed European producer of high-performance tool and die steels engineered for:

- More tougher & crack-resistant

- Easier to machine

- More dimensionally stable.

When combined with a trusted Indian supply partner, they deliver excellence across tooling and die-making applications in India.

Bringing European Tool Steel to India: NLMK Verona × Virat Steels

Through partnership of NLMK Verona with Virat Steels, now Indian industries will have easier access to European-grade steel with reliable local stocking and service & technically supported solutions.

With over 70+ years of experience in the Indian metal industry, Virat Steels remains a trusted partner for toolmakers and manufacturers, supplying premium grades such as:

DIN 1.2714 | 1.2344 | 1.2738 | 1.2379 | HSS M2, M35 , T1 and more backed by the strong manufacturing expertise of NLMK Verona.

Looking for Genuine European Tool Steel with Assured Performance?

Manufacturers, toolmakers, and industry professionals are invited to connect with us at Mach Auto Expo 2026 to explore more premium European Tool & Die Steel solutions.

📍 Venue: LEC, Ludhiana (Punjab)

📅 Date: 20th Feb -23rdFeb 2026

Visit us to discuss tooling challenges, explore NLMK Verona steel grades, and understand how the right material choice can deliver longer tool life and consistent performance.

Quality Crisis in Tool Steels-Why Reliability matters today?

The domestic steel sector is passing through one of its most challenging phases in recent times. Rising raw material costs, uneven quality, supply chain disruptions, and intense price competition have put immense pressure on both the manufacturers and end users. Even a few established German companies also have sold out or shut down their mills and facilities.

While demand from forging, automotive, plastics, and heavy engineering sectors continues, it is becoming more difficult to find die steel and truly high quality tools.

A Growing Industrial Risk

Unfortunately, today many buyers are being misled in the name of “European material”. The major concern is the manipulation of materials by certain suppliers. They charge premium prices while supplying sub-standard materials under the label of premium brands.

What actually happens- is that such suppliers focus only on short-term gains instead of true quality & they may win orders temporarily, but in doing so they break the trust between genuine steel suppliers and end users and ultimately damage the reputation of the image of genuine suppliers who truly deliver certified, high-quality steel.

Industry Challenges: When Solutions Matter the Most

Across industrial sectors, manufacturers are experiencing

- Fluctuating domestic quality

- Shorter tool life

- Premature cracking and

- Increasing expectations for precision and performance.

These issues directly impact productivity, machining accuracy, and overall tool life. In such a scenario, access to reliability, quality, the world-class steel becomes truly essential.

What industries need today is consistent, high-grade steel that meets global standards — not just in name, but in actual performance. This is where European steel material makes a clear difference, enabling higher productivity and long-term growth.

European Tool Steel: Now Closer to Indian Manufacturers

Until now, Only selected suppliers in India have truly been able to offer imported European tool and die steel grades to manufacturers. Over 70 years’ experience in metal domain , Virat Special Steels, India is changing this scenario by making these Premium European Steels more accessible to the Indian industry through strong local stocking, quick service, and technical support guidance with seamless performance and precision right on their shop floor.

Premium European tool steel is no longer out of reach — it is now locally available, reliable and ready to support the Indian manufacturing through Virat Special Steels.

Choosing the best Tool and Die Steels for your Pressure Die Casting needs?

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

- H13 Steels: DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

- H11 Steels: DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

- H21 Steels: DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more :

https://www.viratsteels.com/hot-work-steel.html

https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

The Significance of M2 Steel in the Cutting Tools Industry!

M2 Steel, also known as AISI M2 or DIN 1.3343, is a high-speed tool steel that is part of the tungsten-molybdenum series. This type of steel is renowned for its excellent combination of toughness, wear resistance, and red hardness, which are essential qualities for cutting tools used in high-speed applications.

One of the leading suppliers of M2 Steel in India is Virat Special Steels Pvt Ltd. They have carved a niche in the market by offering high-quality M2 steel that adheres to stringent industry standards. The steel provided by Virat Special Steels is meticulously processed to ensure superior performance in various demanding applications. This makes it an ideal choice for manufacturers who require reliable materials that can withstand the rigors of high-speed operations.

The company’s commitment to quality is evident in the detailed technical support and advice they offer to clients. They guide customers on the best practices for utilizing their steel grades, ensuring that the full potential of M2 Steel is harnessed in their cutting tools.

For businesses looking to enhance their cutting tools’ efficiency and longevity, exploring the offerings of Virat Special Steels could be a step in the right direction. Their expertise in the field and the quality of their M2 Steel could contribute significantly to the performance and success of cutting tools in various industries.

For more information on M2 Steel and its applications, or to inquire about Virat Special Steels‘ products and services, interested parties are encouraged to reach out through the company’s contact channels.

Contact us today to learn more about our products and services!

https://www.viratsteels.com/m2.html

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📞+91 98140 21775

Exploring Tool and Die Steel Supplier in Faridabad?

When it comes to tool and die steel suppliers in Faridabad, there are several options to explore. Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Faridabad!

Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made solutions. With state-of-the-art plants in #Gurugram and #Ludhiana, they have established a strong distribution network across India.

Available Grades:

- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

Quality Assurance and Examination:

Virat Special Steels has an impressive quality assurance facility, including chemical tests, spectrometry, ultrasonic examinations, and hardness testing. This ensures optimal steel selection for specific applications and cost optimization in the long run.

Make In INDIA:

They offer competitive prices, top-notch quality, and prompt service, positioning themselves as a reliable “Make In INDIA” choice for their customers.

For more information, you can explore their details:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-Faridabad/

Remember to explore this suppliers and find the right fit for your specific tool and die steel requirements in Faridabad!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📧 info@viratsteels.com 📞 +91-98140 21775

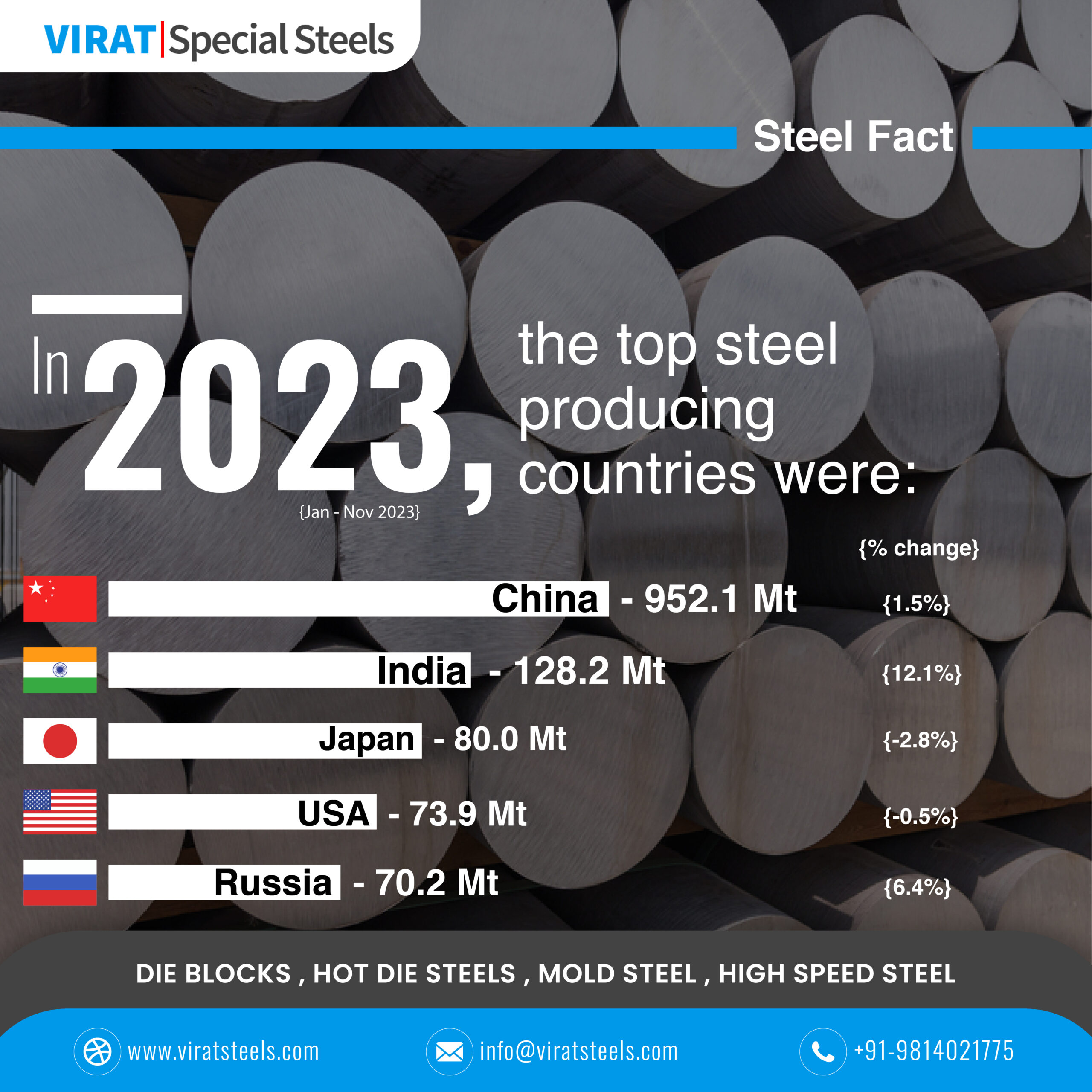

Top 5 Steel Producing Countries in the world!

The top five steel-producing countries in the world as of 2024!

China: Continues to lead as the world’s largest steel producer. India: Maintains its position as the second-largest steel producer with significant production volumes. Japan: Ranks third in steel production, showcasing its industrial capacity. United States: Comes in fourth, contributing a substantial amount to global steel production. And Russia: Holds the fifth spot in the list of top steel producers.

These countries play a pivotal role in the global steel industry, driving innovation and supply in a market that’s essential for various sectors, including construction, automotive, and infrastructure.

According to World Steel Association top countries Steel produced in November 2023:

1️⃣ China: 76.1 Mt produced in November 2023, up by 0.4% from November 2022.

2️⃣ India: 11.7 Mt produced, showing an impressive increase of 11.4%.

3️⃣ Japan: Produced 7.1 Mt, with a slight decrease of 0.9%.

4️⃣ United States: Produced 6.6 Mt, marking a solid increase of 6.1%.

5️⃣ Russia: Estimated to have produced 6.4 Mt, up by a substantial 12.5%.

📊 South Korea, Germany, Türkiye, Brazil, and Iran also contribute significantly to global steel production. Let’s keep an eye on these trends! 💡 Source: World Steel Association (worldsteel)

China produced 76.1 Mt in November 2023, up 0.4% on November 2022. India produced 11.7 Mt, up 11.4%. Japan produced 7.1 Mt, down 0.9%. The United States produced 6.6 Mt, up 6.1%. Russia is estimated to have produced 6.4 Mt, up 12.5%. South Korea produced 5.4 Mt, up 11.9%. Germany produced 2.7 Mt, down 2.4%. Türkiye produced 3.0 Mt, up 25.4%. Brazil produced 2.7 Mt, up 3.8%. Iran is estimated to have produced 3.0 Mt, up 7.6%.

Ref. Source – by World Steel Association (worldsteel)

The World Steel Association (#worldsteel) is one of the largest and most dynamic industry associations in the world, with members in every major steel-producing country. World steel represents steel producers, national and regional steel industry associations, and steel research institutes. Members represent around 85% of global steel production.

The Leading Company VIRAT SPECIAL STEELS PVT. LIMITED , INDIA.,is one of the largest Importer, Exporter and Stockist of Die Blocks ( DIN 2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

We are fully stocked up & ready to dispatch below material. Don’t delay! Order your materials, leave a message, or call right away to discuss your needs.

👑Die Blocks (Din 1.2714/DB6)

👑Hot Die Steels (DIN 2343, 2344/H11, H13)

👑Plastic Mold Steels (DIN 2738, 2311, P20)

👑High Speed Steels (DIN 3243, 3343 / M2, M35)

👑HCHCr (DIN 2379, 2080 / D2, D3)

👑ALLOY STEELS, EN-SERIES

For more information visit

https://www.viratsteels.com/

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

What are the main challenge does Steel industry is facing now?

The Tool and Die Steel industry faces several common issues that can impact productivity, quality, and overall efficiency. The top five key challenges and potential solutions:

- Material Selection:

😒 Choosing the right tool and die materials for specific applications can be challenging.

👉Solution: Conduct thorough material analysis and consider factors like hardness, toughness, and wear resistance. Collaborate with material experts to make informed decisions. - Tool Wear and Failure:

😒Tools and Dies can experience wear and failure over time, affecting the quality of the produced parts.

👉Solution: Implement a regular maintenance schedule to inspect and replace worn-out parts. Use high-quality tool steels and coatings to enhance durability. - Heat Treatment Issues:

😒Inconsistent heat treatment can lead to variations in hardness and other material properties.

👉 Solution: Develop and adhere to precise heat treatment processes. Monitor and control temperature, quenching, and tempering to ensure consistent results. - Precision and Tolerance Challenges:

😒Achieving tight tolerances and precision in manufacturing can be difficult.

👉Solution: Invest in high-precision machining equipment and regularly calibrate machines. Implement quality control measures such as statistical process control (SPC) to monitor and improve tolerances. - Tool Design Complexity:

😒Complex tool and die designs can lead to increased production time and costs.

👉Solution: Utilize computer-aided design (CAD) software to streamline the design process. Optimize designs for manufacturability to reduce complexity and improve efficiency.

Addressing these common issues requires a holistic approach that combines technological innovation, skilled workforce development, and robust quality control measures.

Virat Special Steels can assess the quality, mechanical properties, structural integrity, and dimensional accuracy of their die blocks. This helps them deliver reliable and high-quality products to their customers, meeting their expectations and ensuring successful forming processes.

Contact Us Today:

Ready to elevate your projects with top-quality die steel?

Contact VIRAT SPECIAL STEELS PVT. LIMITED , INDIA today!

Learn More:

https://www.viratsteels.com/

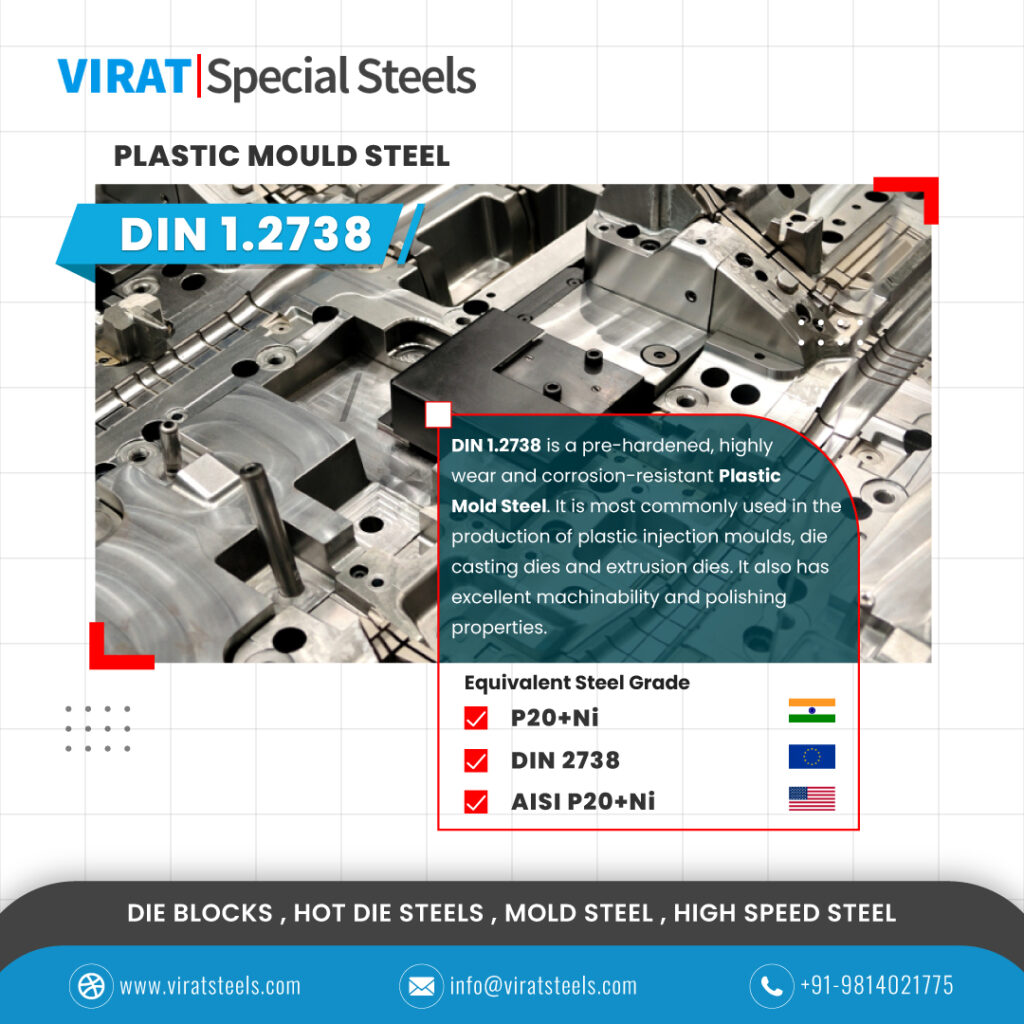

Are you looking for PLASTIC MOULD STEEL in India?

Plastic mould steels are widely used for manufacturing mould for plastic.

Get in touch with us today to place your requirement!

DIN 2738 #PlasticMouldSteel, The equivalent grade P20+Ni | DIN 2738 | AISI P20+Ni …

DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

Although less expensive options such as Aluminum exist for making moulds to be used for shaping plastic, steel is most often the optimum one. It may be impose more investment to begin with but this is offset by its undoubtedly greater operational life and better finish.

Also the specialized steels that have been created for plastic moulding make for rapid process speed – for any duration it can handle more repetitions than other materials and so enhance productivity. DIN 1.2738 Steels are low Carbon consisting of Carbon between 0.35 to 0.45%

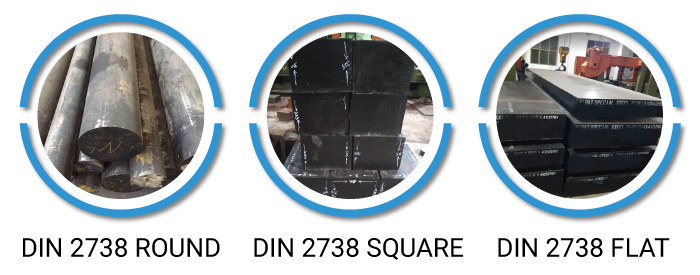

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of DIN 2738 steel in flat, square and round bar. We provide steel in all sizes as your requirements.

Learn more:

https://www.viratsteels.com/p20ni.html

For more information Contact us:

info@viratsteels.com, +91-9814021775