Exploring the reliable Tool and Die Steel Supplier in MIDC, Chakan!

Chakan MIDC, the bustling industrial hub near Pune, Maharashtra, is a testament to India’s manufacturing prowess. Known for its robust engineering, pharmaceuticals, and, most notably, automotive sectors, Chakan has earned the moniker ‘Auto Hub Center of India.’ This industrial growth is fueled by its strategic location, excellent infrastructure, and seamless connectivity to major cities like Pune and Mumbai.

Amidst this industrial landscape, one name stands out: Virat Special Steels. As a leading supplier of tool and die steel, plastic mold steel, high-speed steel, and alloy steel, Virat Special Steels is pivotal in driving growth and efficiency within Chakan’s manufacturing sector. Their extensive product range includes:

- DIE STEEL (HH 370 – 410 BHN) (DB6 / DIN-1.2714 / AISI L6)

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311, AISI P 20)

- HIGH SPEED STEELS (DIN 3243, 3343 / AISI M2, M35)

- COLD WORK STEELS – HCHCr. (DIN 2379, 2080 / AISI D2, D3)

- ALLOY STEELS, EN-SERIES, and more.

Virat Special Steels doesn’t just supply materials; they offer value-added services that cater to the diverse needs of the industry. From material machining to providing cut pieces and tailor-made materials, their offerings are comprehensive. What truly sets them apart is their commitment to metallurgical expertise and quality assurance, ensuring that clients receive not just products but complete solutions.

The state-of-the-art plants in Gurugram and Ludhiana are where the magic happens. Equipped with cutting-edge technology and manned by a skilled workforce, these facilities embody the company’s dedication to excellence. Rigorous quality control measures are the norm here, ensuring that every product that leaves the premises meets the highest standards of quality and reliability.

Virat Special Steels is more than a supplier; it is a partner in the industrial growth of Chakan, contributing to the region’s reputation as a powerhouse of manufacturing and engineering. Their relentless pursuit of excellence and customer satisfaction is a beacon for other companies in the industry, proving that with the right approach, Indian manufacturing can indeed make a mark on the global stage.

You can explore their offerings on their website

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-midc-chakan/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📞 +91 98140-21775

Exploring the reliable Tool and Die Steel Supplier in MIDC, Bhosari!

Bhosari MIDC, nestled within the Pimpri-Chinchwad area of Pune, is traditionally celebrated for its vibrant cultural and sports activities. However, it’s the industrial prowess of the Bhosari Maharashtra Industrial Development Corporation that has catapulted this region into the limelight. As the largest industrial expanse in the vicinity, it boasts a diverse array of manufacturing sectors. From plastic mold industries to die casting, and from engineering to machinery industries, the demand for high-quality tool and die steels is ever-present and growing.

For years, Virat Special Steels, with its headquarters in Gurgaon, has been at the forefront of the tool and die steel market in Bhosari. Their commitment to delivering high-quality products, coupled with unparalleled technical support and value-added services, has not only met but exceeded the expectations of the local industries. This has cemented Virat Steels‘ reputation as the most reliable and incredible supplier in the region.

The product list of Virat Special Steels reads like a testament to their dedication to quality and innovation:

- DIE STEEL (HH 370 – 410 BHN) (DB6 / DIN-1.2714 / AISI L6)

- HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311, AISI P 20)

- HIGH SPEED STEELS (DIN 3243, 3343 / AISI M2, M35)

- COLD WORK STEELS – HCHCr. (DIN 2379, 2080 / AISI D2, D3)

- ALLOY STEELS, EN-SERIES, and more.

The state-of-the-art plants located in Gurugram and Ludhiana are the backbone of Virat Special Steels‘ operations. These facilities are where the magic happens—where cutting-edge technology merges with the expertise of a skilled workforce, all under the watchful eye of rigorous quality control protocols. It’s this combination that enables Virat Special Steels to deliver nothing but excellence.

As the industrial landscape continues to evolve, the role of companies like Virat Special Steels becomes increasingly significant. They are not just suppliers; they are pioneers leading the charge in the industrial revolution of Bhosari MIDC, shaping the future of manufacturing with every steel bar forged and every mold cast. It’s a narrative of growth, quality, and reliability that resonates across the manufacturing sectors of Bhosari and beyond.

You can explore their offerings on their website

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-midc-bhosari/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📞 +91 98140-21775

Exploring the top quality Plastic Mold Steel Supplier in India?

Are you looking for quality Plastic Mold Steel in India?

When it comes to molding dreams, Virat Special Steels doesn’t just offer steel—it crafts possibilities!

Virat Special Steels is a reputable supplier, and they’ve got some interesting offerings. Specifically, let’s talk about DIN 1.2738, also known as DIN 2738 Mould Steel or Plastic Mould Steel 1.2738.

DIN 2738 is the go-to choice for the plastic mold industry, especially when dealing with those big, beefy steel mold components. It’s like the reliable friend who handles high-temperature settings and tough mechanical conditions without breaking a sweat.

DIN 1.2738 is specially designed for plastic injection die molds. It boasts some cool features: excellent sharpening properties, photo-etching capabilities, high purity, and good homogeneity. Think of it as an upgraded version of plastic mold steel 2311, which usually comes in a pre-hardened condition. In that state, its hardness ranges from 280 to 320 HB (that’s on the Brinell scale). The secret sauce? An extra 1% nickel content that enhances through-hardening.

High Hard Version (HXM 24): Now, if you’re looking for something with a bit more oomph, consider the modified version of 2738. It’s like the rockstar sibling—DIN 2738 High Hard. This one cranks up the hardness to a whopping 360-400 BHN (that’s Brinell Hardness Number). They’ve thrown in some extra alloy elements to give it extra life and outstanding polishing capabilities. Imagine your mold components gleaming like they’re ready for a red carpet event!

Application:

DIN 2738 tool steel is the go-to choice for the plastic mold industry, especially when dealing with large steel mold components. It’s often provided pre-hardened and tempered, sitting pretty in the 280-320 HB hardness range. Why? Because it can handle high-temperature settings and tough mechanical conditions like a champ. Plus, it’s got better polishability than its cousin, 1.2312 (AISI P20+S), and plays nice with machining.

Steel Properties:

– Tensile Strength: 850 MPa – 1100 MPa

– Yield Strength: 770 MPa – 980 MPa

– Hardness: 235 HB

– Elongation: 13% – 16%

– Impact Toughness: 20 J/cm² – 42 J/cm²

– Modulus of Elasticity: 205 x 10³ N/mm²

Virat Special Steels offers Plastic Mold Steel (High Hard) with a hardness range of 410-429 BHN. They also provide Modified 2738 (HH) steel, specifically designed for plastic mold manufacturers. These steels are suitable for applications requiring high hardness and durability, making them ideal for creating molds that withstand significant wear and tear during the molding process.

It’s got better polishability than its cousin, 1.2312 (AISI P20+S). So, whether you’re molding plastic widgets or creating intricate shapes, DIN 2738 has your back like a trusty sidekick.

To get detailed Modified 2738 (HH) steel industrial grade steels, visit the website – www.viratsteels.com

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

We Provide our Special Steels in All Cities in India:

- Agra, Alwar, Ambala, Anand, Bhiwadi, Dehradun,

- Ghaziabad, Haridwar, Rudrapur, Delhi, Faridabad,

- Kanpur, Noida, Gurgaon, Manesar, Kundali,Chandigarh,

- Waluj , Vadodara, Pimpri – Chinchwad, Rajkot, Jaipur,

- Ahmedabad, Pithampur, Surat, Amravati, Vadodara,

- Indore, Bhopal, Ranchi, Jamshedpur, Howrah,Kolkata,

- Pune, Thane, Nashik, Mumbai, Navi Mumbai, Nagpur,

- Ambattur, Bangalore, Belgaum, Chittoor, Dindigul,

- Hyderabad, Ernakulam, Chennai, Secunderabad,

- Visakhapatnam, Coimbatore, Mysore, Nellore, Kochi,

- Thiruvananthapuram, Trivandrum, Vijayawada, Guntur,

- Tirupati, Nazarathpet, Kakinada, Kurnool and many

Exploring the Top Notch Tool and Die Steel Supplier in MIDC, Nashik!

Nashik, the burgeoning industrial city of Maharashtra, is rapidly carving a niche for itself in the tool and die steel sector. Situated at a strategic distance from Mumbai and Pune, Nashik‘s conducive climatic and geographical characteristics have fostered an environment ripe for industrial growth.

The city’s expansion is evident in its bustling industrial areas (MIDC) such as Satpur, Ambad, Gonde, Sinnar, and Igatpuri, which are home to a myriad of industries ranging from small-scale startups to large-scale enterprises.

The tool and die steel industry in Nashik is a testament to the city’s industrial prowess. These industries are pivotal in manufacturing and supplying an array of tools, dies, molds, and other essential components that cater to diverse sectors including automotive, aerospace, and medical. Among the leading suppliers is Virat Special Steel, a company that has tapped into the market’s potential by addressing the unique demands of these sectors with a commitment to quality and customization.

What sets Virat Special Steels apart is not just their product range but their commitment to excellence. They offer metallurgical advice, tapping into their deep expertise to ensure that clients receive not only the best materials but also the knowledge to use them effectively. This dedication to quality assurance and expert guidance positions Virat Special Steels as a reliable partner for industrial enterprises in MIDC, Nashik and beyond.

Available Grades:

- Die Steel (HH 370 – 410 BHN): Grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

The city’s industrial development is not just limited to the manufacturing of tool and die steel. Nashik is also known for its vineyards and wineries, earning it the moniker “Wine Capital of India.” The city’s rich history and culture, coupled with its religious significance, add layers to its identity beyond its industrial achievements.

As Nashik continues to grow, the tool and die steel industry stands as a pillar of its industrial sector, driving innovation and quality. With companies like Virat Steels at the forefront, Nashik is poised to make significant contributions to the manufacturing landscape, not just within Maharashtra but on a national scale. The city’s journey from a historical and cultural landmark to an industrial hub is a narrative of progress and potential, signaling a promising future for its industries and the economy at large.

You can explore their offerings on their website

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-midc-nashik/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📨 info@viratsteels.com 📞 +91 98140-21775

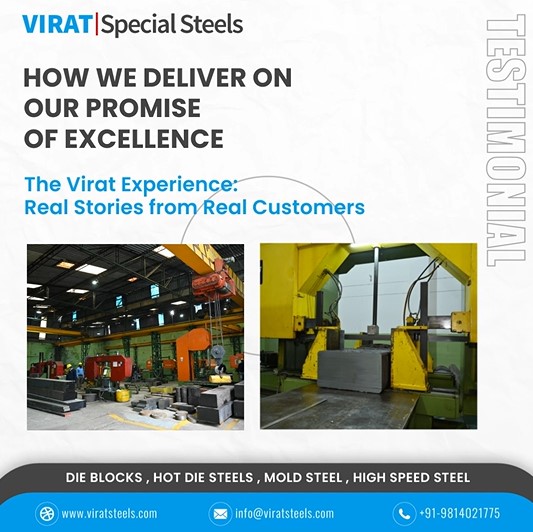

How we deliver on our promise of excellence?

From Steel to Success: Our Customers’ Journey.

How we deliver on our promise of excellence, the Virat Experience…

Virat Special Steels Pvt. Ltd. has built a legacy of excellence, and their commitment to quality resonates with their loyal customers. Let’s delve into the Virat Experience through real stories from those who have trusted their steel solutions:

“We have a service of more than 10 years with this organization. It is one of the best places to get timely service, and I can personally write about numerous instances that have been etched in my memory. It has indeed been a great journey. Excellent coordination.” – Bharat Forge Kalyani

“Virat Steel is more than great company, works with responsibilities, believe in standard work with very good products and services.” – Jindal Aluminum

“A quick turnaround environment that we operate in. Yet it works! Their inside sales staff provide us with quick quoting service on all inquiries and expedited services can be arranged when required.”- Mahindra CIE Automotive

And Many more…

Virat Special Steels Pvt. Ltd. stands tall as India’s largest stockiest, importer, and supplier of high-quality steel. With a robust infrastructure, a dedicated team, and a legacy dating back to 1957, they continue to be a market leader in serving various industries. Whether it’s Tool & Mould Steels, E-commerce, or IT services, Virat Special Steels delivers excellence.

For more information, you can explore their website:

https://www.viratsteels.com/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬info@viratsteels.com ☎+91 98140-21775

Exploring the top-notch Tool and Die Steel Supplier in IMT Rohtak ?

Rohtak, a city located in the vibrant state of Haryana, India, is rapidly emerging as a beacon of industrial growth and connectivity. With its strategic position on National Highway 9, Rohtak enjoys seamless connectivity to the national capital, Delhi, and other significant urban centers, fostering an environment conducive to industrial development and economic prosperity.

The Industrial Model Town (IMT) in Rohtak, a visionary project spearheaded by the Haryana State Industrial and Infrastructure Development Corporation (HSIIDC), stands as a testament to the region’s commitment to industrial innovation. This industrial enclave is not just a cluster of factories and workshops; it is a dynamic ecosystem where precision engineering, metal processing, and tool and die manufacturing converge to create a robust manufacturing sector.

At the heart of IMT Rohtak‘s industrial landscape are specialized industries that focus on tool and die steel—a critical component in various manufacturing processes. These industries are the unsung heroes that support the manufacturing sector, providing the essential tools and components that keep production lines moving and innovation thriving.

Among the many industrious players in IMT Rohtak, Virat Special Steels Private Limited is carving out a niche for itself as a trusted supplier of tool and die steels. Their dedication to quality and customer service is evident in their value-added offerings, such as precision material machining, custom-cut pieces, and tailor-made materials designed to meet the unique needs of diverse industries.

What sets Virat Special Steels apart is not just their product range but their commitment to excellence. They offer metallurgical advice, tapping into their deep expertise to ensure that clients receive not only the best materials but also the knowledge to use them effectively. This dedication to quality assurance and expert guidance positions Virat Special Steels as a reliable partner for industrial enterprises in Rohtak and beyond.

Available Grades:

- Die Steel (HH 370 – 410 BHN): Grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

As Rohtak continues to grow and evolve, the synergy between its strategic location and the industrious spirit of companies like Virat Special Steels will undoubtedly propel the city towards a future marked by industrial excellence and economic vitality. Rohtak is not just on the map of Haryana; it is on the trajectory to becoming a landmark of industrial innovation in India.

For more information on their products and services, interested parties are encouraged to explore their offerings through their official channels https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-rohtak/

Collaborate with Virat Steels in finding more information on website: www.viratsteels.com and can reach on Email : info@viratsteels.com. or Ph: 98140-21775 to obtain an abundant supply of tool Steel, die steel and mold steels at the most affordable pricing .

Exploring the trusted Tool and Die Steel Supplier in IMT Kharkhoda!

The industrial landscape of India is rapidly evolving, and a significant contributor to this growth is the Industrial Model Township (IMT) Kharkhoda. Nestled in the Sonipat district of Haryana, near the bustling metropolis of Delhi, IMT Kharkhoda stands as a testament to the Haryana State Industrial and Infrastructure Development Corporation’s (HSIIDC) vision of fostering industrial development.

IMT Kharkhoda has been meticulously designed to accommodate a diverse array of industrial sectors. From automotive to engineering, electronics to textiles, and chemicals to name a few, it provides an environment that nurtures both large-scale and small-scale industries. This industrial hub has become particularly renowned for its tool and die steel sector, with Virat Special Steel emerging as a prominent name in the field.

For years, Virat Special Steel has distinguished itself as a reliable supplier of tool and die steels in India, meeting the exacting demands and specifications of manufacturers. With large steel yards in Gurgaon, a robust distribution network across India, a well-equipped quality assurance laboratory, and a team of experienced professionals, the company has solidified its reputation in the industry.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Virat Special Steel’s commitment to the manufacturing industries in IMT Kharkhoda is evident in its provision of essential materials for applications such as aluminum extrusion tooling and drop forging. By understanding the unique requirements of their clients, they offer customized solutions tailored to specific grades, sizes, or properties.

The company’s state-of-the-art plants in Gurugram and Ludhiana are the backbone of its operations, ensuring top-notch production through cutting-edge technology, a skilled workforce, and stringent quality control measures. This dedication to excellence positions Virat Special Steels on par with international counterparts, competing with multinational companies like Buderus, DEW, SWG Groditz, and others.

Moreover, Virat Special Steels champions the “Make In INDIA” initiative, offering products that rival those of multinational companies in terms of quality, price, and service. Their commitment to providing great quality at competitive prices, coupled with prompt servicing, aims to enhance and improve the Cost Per Component (CPC) for their customers.

The rise of IMT Kharkhoda as a key industrial hub, particularly for the tool and die steel industry, is a reflection of the region’s strategic planning and the enterprising spirit of companies like Virat Special Steel. As they continue to contribute to India’s industrial growth, they not only support the local economy but also set a benchmark for manufacturing excellence on a global scale.

For more information on their products and services, interested parties are encouraged to explore their offerings through their official channels. https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-kharkhoda/

Collaborate with Virat Steels in finding more information on website: www.viratsteels.com and can reach on Email : info@viratsteels.com. or Ph: 98140-21775 to obtain an abundant supply of tool Steel, die steel and mold steels at the most affordable pricing .

Exploring a Industrial Tool and Die Steel Supplier in IMT Faridabad!

Faridabad, a thriving industrial city in Haryana, India, stands as a testament to the region’s robust growth and strategic importance in the nation’s manufacturing landscape. With its advantageous location, Faridabad enjoys seamless connectivity to the capital city of Delhi and other significant urban centers, courtesy of extensive road and rail networks. This connectivity not only facilitates the movement of goods but also ensures that the workforce can commute with ease, contributing to the city’s economic dynamism.

The Industrial Model Township (IMT) Faridabad, developed by the Haryana State Industrial and Infrastructure Development Corporation (HSIIDC), epitomizes the state’s commitment to fostering an environment conducive to industrial growth. The township is a beacon for sectors such as automotive, engineering, electronics, textiles, and chemicals, attracting a diverse array of manufacturing activities. A notable niche within this industrial mosaic is the specialization in tool and die steel—a critical component for various manufacturing processes, underscoring the city’s integral role in the broader manufacturing ecosystem.

Amidst this industrial vibrancy, Virat Special Steels Private Limited carves a niche for itself as a premier supplier of tool and die steels to the major industries operating within IMT Faridabad. The company’s portfolio, featuring an array of specialized steels, caters to a wide spectrum of industrial requirements. From DIE STEEL with hardness ranging from 370 to 410 BHN to HIGH SPEED STEELS and ALLOY STEELS, the product list is a reflection of the company’s versatility and alignment with industry needs.

What sets Virat Special Steels apart is not just their comprehensive product range but also their value-added services. Material machining, provision of cut pieces, and the supply of tailor-made materials are just a few examples of how the company goes beyond mere supply to deliver solutions that resonate with the unique demands of their clientele. Furthermore, their commitment to metallurgical expertise and unwavering quality assurance positions them as a reliable partner in the industrial sector.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

The synergy between Virat Special Steels‘ state-of-the-art facilities in Gurugram and Ludhiana and their skilled workforce is the cornerstone of their operational excellence. Leveraging cutting-edge technology and stringent quality control measures, the company ensures that each product not only meets but exceeds industry standards.

In conclusion, Faridabad’s industrial prowess, augmented by the presence of companies like Virat Special Steels, is a clear indicator of the region’s pivotal role in India’s manufacturing narrative. As the city continues to evolve and expand its industrial footprint, it remains a shining example of progress and innovation in the manufacturing domain.

For more information on their products and services, interested parties are encouraged to explore their offerings through their official channels. https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-faridabad/

Collaborate with Virat Steels in finding more information on website: www.viratsteels.com and can reach on Email : info@viratsteels.com. or Ph: 98140-21775 to obtain an abundant supply of tool Steel, die steel and mold steels at the most affordable pricing .

Exploring the reliable Tool and Die Steel Supplier in IMT Sohna?

IMT Sohna is an industrial estate developed by HSIIDC (Haryana State Industrial and Infrastructure Development Corporation). located near the Delhi-Mumbai Industrial Corridor (DMIC), is poised to attract various industries, those using tool and die steel for the production of precision components for automotive, aerospace, electronics, and many other industries.

IMT Sohna hosts a variety of industries such as Tool and Die Manufacturing , Metal Processing , Forging Industries, Precision Engineering and Machining etc. For many years, Virat Special Steel has been stood out in these industries as one of a trustworthy supplier of tool and die steels as because of meeting the demands and specifications of manufacturers. possessing its own large steel yards in Gurgaon, a strong distribution network across India, a well-equipped quality assurance laboratory, and an experienced and supportive team of expertise.

Virat Special Steels Private Limited is establishing itself as a most trusted supplier of tool and die steels in the major industries of IMT Sohna. Their value-added services, such as material machining, cut pieces, and tailor-made materials, cater to diverse industrial needs. Moreover, their commitment to providing metallurgical advice by their expertise and quality assurance sets them apart as a reliable and incredible supplier.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Our state-of-the-art plants in Gurugram and Ludhiana ensure top-notch production. Cutting-edge technology, skilled workforce, and rigorous quality control—Virat Special Steels delivers excellence!

Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

For more information on their products and services, interested parties are encouraged to explore their offerings through their official channels. https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-sohna/

Collaborate with Virat Steels in finding more information on website: www.viratsteels.com and can reach on Email : info@viratsteels.com. or Ph: 98140-21775 to obtain an abundant supply of tool Steel, die steel and mold steels at the most affordable pricing .

Exploring the trusted Tool and Die Steel Supplier in IMT Bawal?

IMT Bawal, located in the Rewari district of Haryana and part of the National Capital Region (NCR), has rapidly developed into a significant industrial hub. Its strategic location and connectivity have attracted numerous industries and manufacturing units. The Haryana State Industrial and Infrastructure Development Corporation (HSIIDC) has established several industrial estates in Bawal, with IMT Bawal playing a crucial role in both the local economy and the larger Delhi-Mumbai Industrial Corridor (DMIC) project.

In terms of industries, IMT Bawal has experienced rapid industrialization in recent years, with several sectors contributing to its economic growth includes Tool and Die Manufacturing , Steel and Metal Processing , Forging Industries , Precision Engineering and Machining etc.

In these sectors Virat Steels stand out as a leading supplier of tool , die steel , plastic mold steel, high-speed steel, and alloy steel. in IMT Bawal, driving growth and efficiency in the manufacturing, forging, and other major industries. Their value-added services, such as material machining, cut pieces, and tailor-made materials, cater to diverse industrial needs. Moreover, their commitment to providing metallurgical advice by their expertise and quality assurance sets them apart as a reliable and incredible supplier.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Our state-of-the-art plants in Gurugram and Ludhiana ensure top-notch production. Cutting-edge technology, skilled workforce, and rigorous quality control—Virat Special Steels delivers excellence!

Virat Special Steels offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

For more information on their products and services, interested parties are encouraged to explore their offerings through their official channels. https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-bawal/

Collaborate with Virat Steels in finding more information on website: www.viratsteels.com and can reach on Email : info@viratsteels.com. or Ph: 98140-21775 to obtain an abundant supply of tool Steel, die steel and mold steels at the most affordable pricing .