DB6 Steel best forging steel

now browsing by tag

The Role of DIN 2714 Steel in Forging Industries

The forging industry plays a pivotal role in manufacturing, producing components that form the backbone of various sectors such as automotive, aerospace, construction, and heavy machinery. One material that has emerged as a cornerstone of the forging process is DIN 2714 steel. Renowned for its exceptional properties, DIN 2714 is a hot work tool steel that meets the rigorous demands of forging operations. This blog delves into the characteristics, applications, and benefits of DIN 2714 steel, highlighting its indispensability in the forging industry.

Understanding DIN 2714 Steel

DIN 2714 is a German-standard steel, widely recognized for its high wear resistance, toughness, and thermal stability. It belongs to the family of alloyed steels that exhibit excellent mechanical properties, making it ideal for use in hot forging tools. The composition of DIN 2714 typically includes:

Carbon (C): Contributing to hardness and strength.

Silicon (Si): Enhancing heat resistance.

Manganese (Mn): Improving toughness and hardenability.

Chromium (Cr): Providing corrosion resistance and strength.

Molybdenum (Mo): Increasing high-temperature strength and creep resistance.

This combination of elements gives DIN 2714 its unique ability to withstand extreme operating conditions while maintaining dimensional stability.

Key Properties of DIN 2714 Steel

- High Toughness: With its exceptional toughness, DIN 2714 resists cracking and – chipping, even under heavy loads.

- Excellent Thermal Stability: The steel maintains its mechanical properties at elevated temperatures, making it perfect for hot work applications.

- Wear Resistance: The material can endure prolonged exposure to abrasion, increasing the longevity of forging dies and tools.

- Hardenability: DIN 2714 can achieve a consistent hardness profile, ensuring uniform performance across the material.

Applications in the Forging Industry

DIN 2714 steel’s properties make it indispensable in several forging processes. Some of its primary applications include:

- Forging Dies: The wear resistance and toughness of DIN 2714 make it an excellent choice for dies used in drop forging and upset forging.

- Hot Shear Blades: The steel’s ability to maintain hardness at high temperatures is ideal for cutting hot metal billets.

- Extrusion Tools: DIN 2714’s thermal stability and wear resistance are advantageous in metal extrusion processes.

- Press Tools: These tools require materials that can withstand repeated stress and high impact, making DIN 2714 a preferred choice.

Benefits of Using DIN 2714 Steel

- Increased Tool Life: The superior wear resistance and toughness reduce the frequency of tool replacement, cutting down costs and downtime.

- Improved Efficiency: The steel’s thermal stability allows tools to operate efficiently under high temperatures, enhancing production rates.

- Cost-Effectiveness: Although the initial investment may be higher, the extended tool life and reduced maintenance offset the costs, delivering long-term savings.

- Enhanced Performance: Tools made from DIN 2714 ensure precise and high-quality forging results, meeting stringent industrial requirements.

Conclusion

The forging industry demands materials that can withstand extreme conditions while delivering consistent performance. DIN 2714 steel checks all these boxes, making it a preferred material for manufacturing critical forging tools. By choosing DIN 2714, industries can achieve enhanced productivity, reduced operational costs, and superior product quality.

At Virat Special Steels, we are committed to delivering the highest quality DIN 2714 steel tailored to meet the diverse needs of the forging industry. Partner with us to unlock the potential of this exceptional material and elevate your forging operations to new heights.

FAQ: The Role of DIN 2714 Steel in Forging Industries

1. What is DIN 2714 steel?

DIN 2714 is a German-standard hot work tool steel known for its excellent toughness, wear resistance, and thermal stability. It is widely used in the forging industry for its ability to withstand high temperatures and heavy mechanical loads.

2. What are the key components of DIN 2714 steel?

The primary components of DIN 2714 steel include:

- Carbon (C) for hardness and strength.

- Silicon (Si) for heat resistance.

- Manganese (Mn) for toughness and hardenability.

- Chromium (Cr) for corrosion resistance and strength.

- Molybdenum (Mo) for high-temperature strength.

3. Why is DIN 2714 steel preferred in the forging industry?

DIN 2714 steel is preferred due to its combination of high toughness, wear resistance, thermal stability, and hardenability. These properties make it ideal for manufacturing forging dies, hot shear blades, extrusion tools, and press tools.

4. What applications is DIN 2714 steel suitable for?

DIN 2714 steel is commonly used in:

- Forging dies

- Hot shear blades

- Metal extrusion tools

- Press tools for hot work applications

5. What are the benefits of using DIN 2714 steel in forging?

The key benefits include:

- Prolonged tool life due to high wear resistance

- Improved efficiency in high-temperature operations

- Cost-effectiveness through reduced maintenance and downtime

- Consistent and precise forging results

6. How does DIN 2714 compare with other hot work tool steels?

DIN 2714 stands out for its balanced properties, such as toughness, wear resistance, and heat resistance. It offers an optimal combination of durability and performance, making it a reliable choice for heavy-duty forging tools.

7. Can DIN 2714 steel be customized for specific applications?

Yes, DIN 2714 steel can be heat-treated and machined to meet specific requirements of different forging applications. Working with a trusted supplier ensures customization tailored to your operational needs.

8. What is the typical service life of tools made from DIN 2714 steel?

The service life varies based on the application, maintenance practices, and operating conditions. However, DIN 2714’s durability ensures longer tool life compared to many other materials.

9. How should DIN 2714 steel be maintained to maximize its performance?

Proper maintenance includes regular inspection for wear, timely heat treatment, and ensuring that tools operate within their recommended temperature range. This helps in prolonging the tool’s service life.

10. Where can I source high-quality DIN 2714 steel?

Virat Special Steels is a trusted supplier of premium DIN 2714 steel, offering products tailored to the needs of the forging industry. Contact us to learn more about our offerings and how we can support your business.

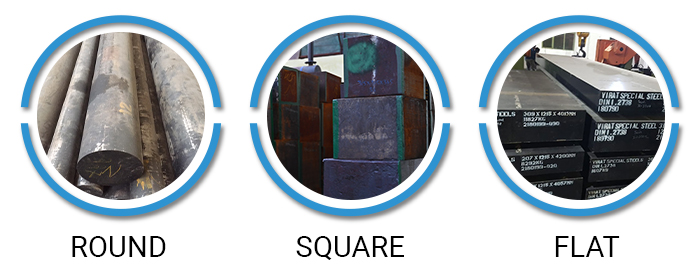

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of DIN 2714 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2714 die steel is available in flat, square and round shape.

Consult our team who will assist you for DIN 2714 steel query.

https://www.viratsteels.com/din-2714.html

🌐https://www.viratsteels.com 📩info@viratsteels.com 📲+91-98140-21775

DB6 Steels – The Cornerstone of Precision Engineering

Introduction to Virat Special Steels Pvt. Limited

For over five decades, Virat Special Steels Pvt. Limited has stood at the forefront of the specialty steel industry, not just in India but globally. As one of the largest importers, exporters, and stockists of die blocks, tool steels, die steels, special steels, and alloy steels, we pride ourselves on providing unmatched quality.

Our collaborations with premier steel manufacturers, including Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals, enable us to stock and supply the highest quality steels for industries that demand nothing less than precision. Today, we spotlight DB6 steel / DIN 2714, a game-changer in the world of forging and tooling applications.

About Virat Special Steels Pvt. Limited

Virat Special Steels combines expertise and experience to maintain one of India’s most extensive inventories of specialty steels. Whether you’re looking for tool steels for automotive molds or durable materials for aerospace components, we offer a one-stop solution. Our trusted partnerships with leading manufacturers ensure that the best forging steel meets your exact requirements.

What is DB6 Steel?

DB6 steel is a premium-grade tool steel revered for its exceptional durability, toughness, and machinability. Often categorized under the 1.2714 steel grade, it’s an indispensable material in applications requiring the highest standards of wear resistance and impact strength.

DB6 Steel / DIN 2714 Composition and Properties

The magic of DB6 material lies in its precise composition. It contains chromium, molybdenum, and vanadium, making it perfect for tasks requiring optimal hardness and ductility. Key properties include:

- High toughness: Resistant to deformation under extreme pressure.

- Superior machinability: Easily shaped without losing structural integrity.

- Wear resistance: Prolongs the lifespan of tooling components.

Benefits of Using DB6 Steel

When it comes to specialized industrial needs, DB6 steel / DIN 2714 excels across all parameters, such as:

- Performance in High-Stress Environments: Designed for heavy-duty molds and die blocks that endure rigorous use.

- Longevity and Cost-Efficiency: A long-lasting material reduces frequent replacement costs, delivering an excellent return on investment.

- Adaptability: Compatible with diverse machining processes.

DB6 Material Properties

Engineered for reliability, DB6 steel / DIN 2714 delivers:

- Exceptional hardness levels: Ideal for high-performance tooling.

- Resistance to cracking or deforming: Suitable for forging operations.

Applications of DB6 Steel / DIN 2714

A versatile material, DB6 steel / DIN 2714 finds usage in industries that require precision and durability, including:

- Automotive Industry: Fabricating molds for vehicle components.

- Aerospace Applications: High-precision tooling for aircraft parts.

- Heavy Machinery Manufacturing: Optimal for creating durable machinery parts.

Why Choose Virat Special Steels for DB6 Steel / DIN 2714?

At Virat Special Steels, we deliver unmatched quality by combining expertise with partnerships forged with trusted manufacturers. Here’s what sets us apart:

- Wide Inventory: Always ready to meet large-scale and urgent orders.

- Stringent Quality Checks: Every piece of steel undergoes rigorous testing.

- Comprehensive Customer Support: From material selection to logistics, we’ve got you covered.

Partnerships with Leading Manufacturers

Virat Special Steels owes its reputation not only to its unmatched inventory but also to its strong alliances with the world’s leading steel manufacturers. Our partners include Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals, among others. These collaborations ensure a consistent supply of the highest quality steel in the world, including DB6 steel/ DIN 2714. By sourcing directly from top-tier manufacturers, we guarantee the authenticity and reliability of every material we deliver.

- Swiss Steel DEW specializes in producing high-performance alloy steels.

- NLMK Verona focuses on heavy plate and tool steel production, tailored to precision industries.

- Villares Metals brings cutting-edge technology and stringent testing processes to ensure top-notch steel products.

DB6 vs. High Carbon Steels

When evaluating DB6 steel / DIN 2714 alongside high carbon steels, the distinction becomes apparent. Both materials boast exceptional strength and durability, but DB6 steel/ DIN 2714 takes the lead in versatility and cost-effectiveness. High carbon steels are notorious for their difficulty in machining, which translates into higher production costs. Meanwhile, DB6 steel’s superior machinability and wear resistance make it ideal for applications requiring precision without compromising efficiency.

| Property | DB6 Steel/ DIN 2714 | High Carbon Steels |

| Machinability | High | Moderate |

| Toughness | Superior | High |

| Wear Resistance | Excellent | Moderate |

| Cost-Effectiveness | High | Moderate |

The Environmental Edge of High-Quality Steels

Sustainability in steel manufacturing is no longer optional—it’s essential. Virat Special Steels aligns with global efforts to promote eco-friendly production processes. By sourcing DB6 steel/ DIN 2714 from ethical manufacturers, we ensure minimal waste and a reduced carbon footprint. Furthermore, the durability of DB6 steel/ DIN 2714 significantly reduces the need for replacements, contributing to a greener planet.

- Sustainable Production: Our partners adopt advanced methods to lower emissions.

- Long-Term Efficiency: High-quality materials like DB6 steel / DIN 2714 maximize lifecycle performance, reducing environmental impact.

Ordering DB6 Steel/ DIN 2714 from Virat Special Steels

Choosing Virat Special Steels means investing in a hassle-free experience from start to finish. Our customer-oriented approach ensures:

- Timely Delivery: With one of India’s most extensive inventories, we meet even the most urgent demands.

- Global Reach: From local industries to international markets, we deliver steel wherever you need it.

- Tailored Solutions: Our team assists in selecting the right steel grade for your specific application.

Steps to Place an Order

- Contact us with your requirements.

- Discuss customization options, if needed.

- Confirm your order and await prompt delivery.

Testimonials and Case Studies

Don’t just take our word for it—hear from our satisfied customers across diverse industries. From leading automobile manufacturers to high-tech aerospace companies, our clients vouch for the quality and reliability of DB6 steel/ DIN 2714 supplied by Virat Special Steels.

Real-World Applications

- Automotive Die Blocks: A client reported a 30% reduction in tooling downtime after switching to DB6 steel / DIN 2714.

- Aerospace Components: High stress-resistant properties of DB6 steel / DIN 2714 ensured operational precision in extreme conditions.

- Heavy Machinery: One of India’s top engineering firms improved efficiency by using DB6 steel / DIN 2714 for forging massive machinery parts.

Future of DB6 Steel / DIN 2714 in Engineering Applications

As industries advance, the demand for materials like DB6 steel / DIN 2714 is set to soar. Emerging technologies, such as 3D metal forging and automated machining systems, require steels with both resilience and adaptability—qualities that DB6 steel / DIN 2714 provides in abundance.

Key areas of growth include:

- Renewable Energy Equipment: Durable die blocks and tool steels for wind turbines.

- Precision Medical Equipment: DB6 steel’s machinability opens possibilities in surgical instrument manufacturing.

- Space Exploration: The aerospace industry’s expanding horizons require highly resilient materials like DB6 / DIN 2714.

Closing Thoughts: Why Virat Special Steels?

When it comes to DB6 steel / DIN 2714 and other specialty grades, Virat Special Steels Pvt. Limited remains unmatched in expertise and excellence. With a global network, state-of-the-art inventory, and unwavering commitment to quality, we’re your go-to partner for premium tool and die steels. By choosing Virat Special Steels, you’re not just buying steel; you’re investing in a legacy of reliability and performance.

FAQs

1. What are the key applications of DB6 steel / DIN 2714?

DB6 steel is commonly used in die blocks, molds, and heavy-duty machinery, especially in industries like forging, automotive, aerospace, and tool manufacturing.

2. What makes DB6 steel / DIN 2714 better than high carbon steels?

DB6 steel offers superior machinability, higher toughness, and better cost-efficiency compared to high carbon steels.

3. How does Virat Special Steels ensure the quality of its DB6 steel / DIN 2714?

We partner with global leaders like Swiss Steel DEW and conduct stringent quality checks to ensure consistent reliability.

4. Is DB6 steel / DIN 2714 environmentally friendly?

Yes, DB6 steel’s long lifespan and efficient production processes minimize waste, making it an eco-friendly option.

5. How can I place an order for DB6 steel / DIN 2714 from Virat Special Steels?

Simply reach out with your requirements, and our team will guide you through the process of choosing, customizing, and purchasing.

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA!

https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business!

https://www.viratsteel.in/special-steel-supply-networks/

Watch now:

https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎+91 98140-21775