din2714

now browsing by tag

DB6 vs High Carbon Steels

When it comes to choosing steel for industrial, tooling, or manufacturing purposes, the choice often boils down to the material’s performance, strength, and durability. DB6 steel and high carbon steels are two prominent contenders in various industries. Each has its unique properties, uses, and advantages.

In this article, we’ll break down the differences between DB6 and high carbon steels to help you make the right decision based on your specific needs.

What is DB6 Steel?

Definition and Composition of DB6 Steel

DB6 is a premium-grade, hot-work tool steel that is specifically designed for die and tooling applications. It belongs to the H-series of tool steels and typically contains chromium, molybdenum, and vanadium as its core alloying elements.

Key Properties of DB6 Steel

- Toughness: DB6 exhibits excellent toughness, which helps it resist cracking under high stress.

- Heat Resistance: It maintains its strength at elevated temperatures.

- Wear Resistance: Due to its alloying elements, DB6 resists wear, making it perfect for heavy-use industrial tools.

- Hardness: It strikes a balance between hardness and machinability.

Common Applications of DB6 Steel

- Die Casting Dies: DB6 is frequently used in aluminum and zinc die-casting dies.

- Extrusion Tools: It excels in hot extrusion applications where heat resistance is critical.

- Plastic Molding: DB6 is utilized for injection molding applications due to its durability.

What are High Carbon Steels?

Definition and Composition of High Carbon Steels

High carbon steels are steels with a carbon content between 0.6% and 1.0%, which gives them enhanced hardness and strength compared to low and medium carbon steels.

Key Properties of High Carbon Steels

- Hardness: High carbon steels achieve high hardness levels when properly heat-treated.

- Strength: Their higher carbon content contributes to excellent tensile strength.

- Wear Resistance: High carbon steels resist abrasion effectively in moderate conditions.

- Machinability: They are harder to machine compared to low carbon steels but can be shaped under specific conditions.

Common Applications of High Carbon Steels

- Cutting Tools: Knives, blades, and cutting tools often rely on high carbon steels.

- Springs: Due to their elasticity and strength, high carbon steels are widely used for springs.

- Wires and Cables: Strong wires are frequently made using high carbon steels.

DB6 vs. High Carbon Steels: A Comparative Analysis

Composition Comparison

- DB6 Steel: Contains alloying elements like chromium, molybdenum, and vanadium, which enhance its toughness and resistance to heat and wear.

- High Carbon Steels: Primarily rely on carbon content for their hardness and strength without significant alloying additions.

Hardness and Toughness

- DB6 Steel: While DB6 may not be as hard as high carbon steels, it offers excellent toughness, making it ideal for high-stress industrial uses.

- High Carbon Steels: These steels are extremely hard but less tough, which makes them prone to cracking under extreme conditions.

Wear Resistance

- DB6’s alloyed structure offers superior wear resistance in high-temperature environments.

- High carbon steels provide moderate wear resistance but may degrade under high heat.

Machinability and Workability

- DB6 Steel: Offers good machinability and can be worked into complex shapes.

- High Carbon Steels: More challenging to machine due to their hardness.

Strength and Durability: DB6 vs. High Carbon Steels

DB6 Steel Strength Under Stress:

DB6’s robust toughness makes it ideal for repeated use in high-impact, high-heat scenarios, such as die-casting or extrusion.

High Carbon Steel Performance in High-Stress Environments:

While high carbon steels excel in strength, they are less durable in prolonged high-temperature environments, making them unsuitable for hot work applications.

Heat Treatment: DB6 vs. High Carbon Steels

Heat Treatment Process of DB6 Steel

DB6 is subjected to quenching and tempering processes, which give it optimal toughness and hardness for die applications.

Heat Treatment Process of High Carbon Steels

High carbon steels undergo annealing, hardening, and tempering to achieve high hardness levels.

Differences in Heat Treatment Outcomes

- DB6 retains toughness even after heat treatment.

- High carbon steels become extremely hard but lose some toughness in the process.

Corrosion Resistance

DB6 Steel’s Resistance to Corrosion:

DB6 has better corrosion resistance compared to high carbon steels due to its alloying elements like chromium.

High Carbon Steel’s Corrosion Limitations:

High carbon steels are more prone to rusting and corrosion when exposed to moisture or corrosive environments.

Conclusion

Choosing between DB6 steel and high carbon steels depends entirely on your application. If you need a material with excellent toughness, heat resistance, and wear performance, DB6 steel is your best bet. On the other hand, if cost and hardness are primary considerations, high carbon steels might meet your requirements.

FAQs

1. What is the biggest difference between DB6 and high carbon steels?

The biggest difference lies in their composition. DB6 is an alloyed tool steel, while high carbon steels rely on carbon for their properties.

2. Which steel is better for die and tooling?

DB6 is superior for die and tooling due to its heat resistance and toughness.

3. How do DB6 and high carbon steels respond to heat treatment?

DB6 retains toughness after heat treatment, whereas high carbon steels become extremely hard but lose toughness.

4. Is DB6 steel more expensive than high carbon steel?

Yes, DB6 steel is typically more expensive due to its alloying elements and superior properties.

5. Can high carbon steel replace DB6 in industrial applications?

High carbon steel can be used for specific low-temperature applications, but it cannot match DB6’s performance in hot work environments.

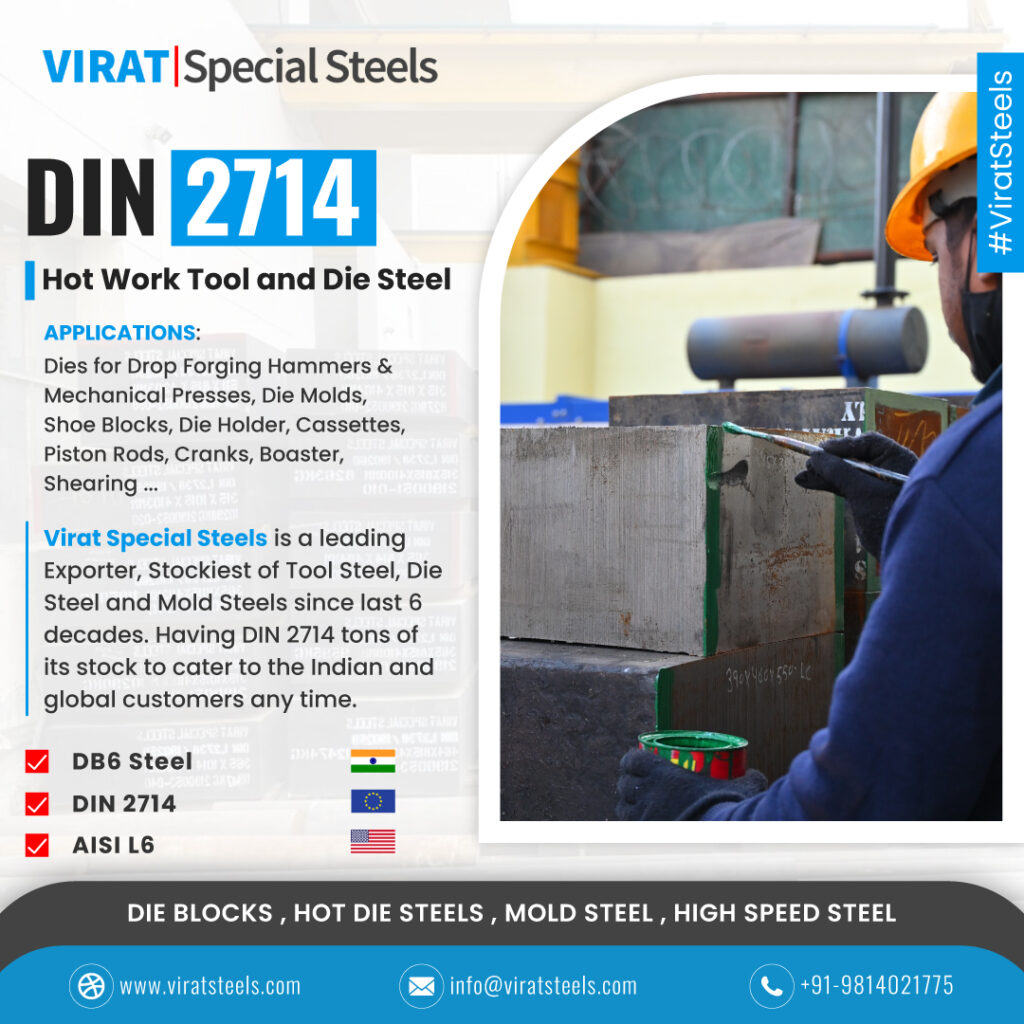

Discover the quality of Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED. Get in touch with us today to place your requirement! Contact us today to buy the best quality DB6 / DIN 2714 steel for your tooling needs! https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📩info@viratsteels.com 📲+91-98140-21775

DB6 Steels – The Cornerstone of Precision Engineering

Introduction to Virat Special Steels Pvt. Limited

For over five decades, Virat Special Steels Pvt. Limited has stood at the forefront of the specialty steel industry, not just in India but globally. As one of the largest importers, exporters, and stockists of die blocks, tool steels, die steels, special steels, and alloy steels, we pride ourselves on providing unmatched quality.

Our collaborations with premier steel manufacturers, including Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals, enable us to stock and supply the highest quality steels for industries that demand nothing less than precision. Today, we spotlight DB6 steel / DIN 2714, a game-changer in the world of forging and tooling applications.

About Virat Special Steels Pvt. Limited

Virat Special Steels combines expertise and experience to maintain one of India’s most extensive inventories of specialty steels. Whether you’re looking for tool steels for automotive molds or durable materials for aerospace components, we offer a one-stop solution. Our trusted partnerships with leading manufacturers ensure that the best forging steel meets your exact requirements.

What is DB6 Steel?

DB6 steel is a premium-grade tool steel revered for its exceptional durability, toughness, and machinability. Often categorized under the 1.2714 steel grade, it’s an indispensable material in applications requiring the highest standards of wear resistance and impact strength.

DB6 Steel / DIN 2714 Composition and Properties

The magic of DB6 material lies in its precise composition. It contains chromium, molybdenum, and vanadium, making it perfect for tasks requiring optimal hardness and ductility. Key properties include:

- High toughness: Resistant to deformation under extreme pressure.

- Superior machinability: Easily shaped without losing structural integrity.

- Wear resistance: Prolongs the lifespan of tooling components.

Benefits of Using DB6 Steel

When it comes to specialized industrial needs, DB6 steel / DIN 2714 excels across all parameters, such as:

- Performance in High-Stress Environments: Designed for heavy-duty molds and die blocks that endure rigorous use.

- Longevity and Cost-Efficiency: A long-lasting material reduces frequent replacement costs, delivering an excellent return on investment.

- Adaptability: Compatible with diverse machining processes.

DB6 Material Properties

Engineered for reliability, DB6 steel / DIN 2714 delivers:

- Exceptional hardness levels: Ideal for high-performance tooling.

- Resistance to cracking or deforming: Suitable for forging operations.

Applications of DB6 Steel / DIN 2714

A versatile material, DB6 steel / DIN 2714 finds usage in industries that require precision and durability, including:

- Automotive Industry: Fabricating molds for vehicle components.

- Aerospace Applications: High-precision tooling for aircraft parts.

- Heavy Machinery Manufacturing: Optimal for creating durable machinery parts.

Why Choose Virat Special Steels for DB6 Steel / DIN 2714?

At Virat Special Steels, we deliver unmatched quality by combining expertise with partnerships forged with trusted manufacturers. Here’s what sets us apart:

- Wide Inventory: Always ready to meet large-scale and urgent orders.

- Stringent Quality Checks: Every piece of steel undergoes rigorous testing.

- Comprehensive Customer Support: From material selection to logistics, we’ve got you covered.

Partnerships with Leading Manufacturers

Virat Special Steels owes its reputation not only to its unmatched inventory but also to its strong alliances with the world’s leading steel manufacturers. Our partners include Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals, among others. These collaborations ensure a consistent supply of the highest quality steel in the world, including DB6 steel/ DIN 2714. By sourcing directly from top-tier manufacturers, we guarantee the authenticity and reliability of every material we deliver.

- Swiss Steel DEW specializes in producing high-performance alloy steels.

- NLMK Verona focuses on heavy plate and tool steel production, tailored to precision industries.

- Villares Metals brings cutting-edge technology and stringent testing processes to ensure top-notch steel products.

DB6 vs. High Carbon Steels

When evaluating DB6 steel / DIN 2714 alongside high carbon steels, the distinction becomes apparent. Both materials boast exceptional strength and durability, but DB6 steel/ DIN 2714 takes the lead in versatility and cost-effectiveness. High carbon steels are notorious for their difficulty in machining, which translates into higher production costs. Meanwhile, DB6 steel’s superior machinability and wear resistance make it ideal for applications requiring precision without compromising efficiency.

| Property | DB6 Steel/ DIN 2714 | High Carbon Steels |

| Machinability | High | Moderate |

| Toughness | Superior | High |

| Wear Resistance | Excellent | Moderate |

| Cost-Effectiveness | High | Moderate |

The Environmental Edge of High-Quality Steels

Sustainability in steel manufacturing is no longer optional—it’s essential. Virat Special Steels aligns with global efforts to promote eco-friendly production processes. By sourcing DB6 steel/ DIN 2714 from ethical manufacturers, we ensure minimal waste and a reduced carbon footprint. Furthermore, the durability of DB6 steel/ DIN 2714 significantly reduces the need for replacements, contributing to a greener planet.

- Sustainable Production: Our partners adopt advanced methods to lower emissions.

- Long-Term Efficiency: High-quality materials like DB6 steel / DIN 2714 maximize lifecycle performance, reducing environmental impact.

Ordering DB6 Steel/ DIN 2714 from Virat Special Steels

Choosing Virat Special Steels means investing in a hassle-free experience from start to finish. Our customer-oriented approach ensures:

- Timely Delivery: With one of India’s most extensive inventories, we meet even the most urgent demands.

- Global Reach: From local industries to international markets, we deliver steel wherever you need it.

- Tailored Solutions: Our team assists in selecting the right steel grade for your specific application.

Steps to Place an Order

- Contact us with your requirements.

- Discuss customization options, if needed.

- Confirm your order and await prompt delivery.

Testimonials and Case Studies

Don’t just take our word for it—hear from our satisfied customers across diverse industries. From leading automobile manufacturers to high-tech aerospace companies, our clients vouch for the quality and reliability of DB6 steel/ DIN 2714 supplied by Virat Special Steels.

Real-World Applications

- Automotive Die Blocks: A client reported a 30% reduction in tooling downtime after switching to DB6 steel / DIN 2714.

- Aerospace Components: High stress-resistant properties of DB6 steel / DIN 2714 ensured operational precision in extreme conditions.

- Heavy Machinery: One of India’s top engineering firms improved efficiency by using DB6 steel / DIN 2714 for forging massive machinery parts.

Future of DB6 Steel / DIN 2714 in Engineering Applications

As industries advance, the demand for materials like DB6 steel / DIN 2714 is set to soar. Emerging technologies, such as 3D metal forging and automated machining systems, require steels with both resilience and adaptability—qualities that DB6 steel / DIN 2714 provides in abundance.

Key areas of growth include:

- Renewable Energy Equipment: Durable die blocks and tool steels for wind turbines.

- Precision Medical Equipment: DB6 steel’s machinability opens possibilities in surgical instrument manufacturing.

- Space Exploration: The aerospace industry’s expanding horizons require highly resilient materials like DB6 / DIN 2714.

Closing Thoughts: Why Virat Special Steels?

When it comes to DB6 steel / DIN 2714 and other specialty grades, Virat Special Steels Pvt. Limited remains unmatched in expertise and excellence. With a global network, state-of-the-art inventory, and unwavering commitment to quality, we’re your go-to partner for premium tool and die steels. By choosing Virat Special Steels, you’re not just buying steel; you’re investing in a legacy of reliability and performance.

FAQs

1. What are the key applications of DB6 steel / DIN 2714?

DB6 steel is commonly used in die blocks, molds, and heavy-duty machinery, especially in industries like forging, automotive, aerospace, and tool manufacturing.

2. What makes DB6 steel / DIN 2714 better than high carbon steels?

DB6 steel offers superior machinability, higher toughness, and better cost-efficiency compared to high carbon steels.

3. How does Virat Special Steels ensure the quality of its DB6 steel / DIN 2714?

We partner with global leaders like Swiss Steel DEW and conduct stringent quality checks to ensure consistent reliability.

4. Is DB6 steel / DIN 2714 environmentally friendly?

Yes, DB6 steel’s long lifespan and efficient production processes minimize waste, making it an eco-friendly option.

5. How can I place an order for DB6 steel / DIN 2714 from Virat Special Steels?

Simply reach out with your requirements, and our team will guide you through the process of choosing, customizing, and purchasing.

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA!

https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business!

https://www.viratsteel.in/special-steel-supply-networks/

Watch now:

https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 info@viratsteels.com ☎+91 98140-21775

Top Sources for Imported Die Steel Blocks DIN 2714 (DB6) in India.

Die steel blocks DIN 2714 could be a great choice for your close die forging applications!

Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED, INDIA

At Virat Special Steels, we take pride in offering a variety of premium tool steels, including the renowned Die Steel Blocks DIN 2714 (DB6). As one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels, we have built a reputation for delivering the best quality products that meet international standards.

Why Choose Virat Special Steels?

We source our tools and die steels from the world’s top manufacturing companies, ensuring that our customers receive only the highest quality materials. Our partners include:

- Swiss Steel Group (DEW)

- Nippon Koshuha Steels Co. Ltd

- Hyundai Steel

- SeAH Besteel Corp

And many more…

Applications of DB6/ DIN 1.2714 Steel

DB6/ DIN 1.2714 steel is commonly supplied in a pre-hardened condition, with a typical working hardness range of 360 to 430 BHN (Brinell hardness number). Its versatility makes it ideal for various applications, including:

- Forging dies

- Die molds

- Shoe blocks

- Die holders

- Piston rods

- Bolster

- Cranks

- Cassettes

- Plastic molds

- Shearing blades

- Tools and more…

Get in Touch with Us Today

Our company maintains the largest steel yards and holds a high level of inventory of special steels, ensuring that we can meet your requirements promptly and efficiently. Based in Gurgaon (Haryana) & Ludhiana (Punjab), India, we are ready to serve your needs.

Discover the quality of Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED. Get in touch with us today to place your requirement! Contact us today to buy the best quality DB6 / DIN 2714 steel for your tooling needs! https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📩info@viratsteels.com 📲+91-98140-21775

Exploring the top-notch DB6 and H13 Steel Supplier in Faridabad?

Nestled in the heart of Haryana, Faridabad is not just a city that benefits from its strategic location, with robust connectivity to Delhi and other major cities, but it is also a burgeoning industrial hub that has been meticulously developed by the Haryana State Industrial and Infrastructure Development Corporation (HSIIDC). The Industrial Model Township (IMT) Faridabad stands as a testament to this growth, housing a plethora of industries that are the backbone of manufacturing sectors such as automotive, engineering, electronics, textiles, and chemicals.

One of the critical components for these manufacturing processes is tool and die steel, a specialized material that is indispensable for the creation and shaping of other products. In this vibrant industrial landscape, Virat Special Steels Private Limited has carved out a niche for itself as a premier supplier of these essential steels. With a reputation for trust and reliability, Virat Special Steels caters to the major industries of IMT Faridabad with a range of value-added services. These include material machining, provision of cut pieces, and the supply of tailor-made materials, all designed to meet the diverse needs of the industrial sector.

What sets Virat Special Steels apart is not just their product offering, but their commitment to excellence. They stand shoulder to shoulder in terms of quality, price, and services with steels of the same grade from multinational giants like Buderus, DEW, SWG Groditz, Nippon, Sanyo, Gloria, BGH, Kind & Co, Swiss Steel, S&B Steel, and Hitachi Steel. Their “Make In INDIA” initiative is particularly noteworthy, offering products that compete on an international level in terms of quality and cost-effectiveness, while also focusing on improving the Cost Per Component (CPC) for their customers.

The dynamic industrial environment of IMT Faridabad, bolstered by the presence of companies like Virat Special Steels, is a driving force behind the region’s economic growth and innovation. It is a shining example of how specialized industries can thrive and contribute to the larger narrative of India’s industrial prowess.

As Faridabad continues to grow and attract investment, it is clear that the city’s industrial sector, with its focus on quality and innovation, is set to play a pivotal role in shaping the future of manufacturing in India.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA has carved out a niche for itself as a premier supplier of these essential steels. With a reputation for trust and reliability, Virat Special Steels caters to the major industries of IMT Faridabad with a range of value-added services. These include material machining, provision of cut pieces, and the supply of tailor-made materials, all designed to meet the diverse needs of the industrial sector.

Why Choose Us?

🔥Top-Notch Quality: Our DB6 and H13 Steels are renowned for their superior performance and durability.

📣Reliability: As a prime supplier, we ensure timely delivery and consistent quality.

🔔Expertise: With decades of experience, we provide unmatched industry knowledge and customer service.

For all your DB6 and H13 steel needs, trust Virat Special Steels!

Contact Us Today! Visit now: https://www.viratsteels.com/

Learn more:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-imt-faridabad/

The Future of Tool and Die Steel Industries in Spain?

A Professional Insight: The tool and die steel industry in Spain is poised for steady growth, reflecting the global market’s expected expansion at a compound annual growth rate (CAGR) of 5.3% from 2022 to 2030. This growth trajectory is underpinned by the inherent qualities of tool steels, which belong to the carbon steel family and are distinguished by their heat resistance, hardness, and durability. The addition of elements such as tungsten, chromium, vanadium, and molybdenum enhances these steels’ performance, making them indispensable in various industrial applications.

Tool steels are integral to the manufacturing sector, finding use in cutting, pressing, extruding, forming, and shearing metals. Their excellent abrasion resistance also makes them the material of choice for injection molds. As industries evolve, the demand for high-quality tool and die steels continues unabated, with technological advancements in heating technologies significantly boosting this demand.

Spain’s tool and die steel industry must navigate challenges posed by technological advancements, market dynamics, and global competition. To maintain and enhance its growth trajectory, the industry needs to invest continuously in research and development and foster collaborative efforts. The positive outlook for Spain’s tool and die steel industry is bolstered by the country’s economic momentum, technological advancements, and strategic positioning within Europe.

Virat Special Steel, a supplier based in Portugal and Spain with roots in India, exemplifies the quality that sets apart the Spanish tool and die steel solutions. Known for its hardness, toughness, wear resistance, and competitive pricing, Virat Steel stands out in demanding manufacturing environments. The company imports from leading manufacturers catering to the specific needs and demands of manufacturers.

A key player in this sector is Virat Special Steels Pvt. Limited, an Indian company that has established itself as a trusted supplier in Spain. Specializing in a wide array of products including tool steel, die steel, plastic mold steel, and high-speed steel, Virat Special Steels Pvt. Limited caters to the diverse needs of its customer base. The company’s dedication to quality and service further solidifies its position in the market.

Virat Steels supply their tool steel bars to forging and automobile engineering companies across all locations in the world… India, Nepal, Dubai, Thailand, Vietnam, Saudi Arabia, United Arab Emirates , Qatar, Kuwait, Iran, Turkey, Portugal, Spain, Poland, UK, USA, Canada, Brazil, Mexico, Belarus, Australia, New Zealand and many more..

The Spanish tool and die steel industry’s future appears promising, with the potential to make significant contributions to this dynamic sector. With strategic investments and a focus on innovation, Spain can solidify its position as a key player in the European and global steel markets.

Exploring the Special Steel VMO Brazil Steel and ABNT VMO?

The steel grade VMO refers to a high-strength alloy steel produced in Brazil, typically used in applications requiring superior mechanical properties. The VMO steel grade from Brazil, also known as ABNT VMO, is a type of special steel primarily used for hot work applications, such as forging dies in high-performance drop hammers.

V: Vanadium, which improves strength, toughness, and wear resistance.

M: Molybdenum, which enhances high-temperature strength and corrosion resistance.

O: Other alloying elements that contribute to the steel’s properties.

This steel grade is commonly used in industries such as automotive, aerospace, and construction, where both high strength and durability are essential. Its specific chemical composition can vary depending on the manufacturer and application, but VMO steel is generally designed for high-performance industrial use.

It’s Hot Work Steel and the equivalent grades are:

- DIN STANDARD: DIN 2714

- BRAZIL: VMO

- JIS: SKT4

The VMO steel grade from Brazil, also known as ABNT VMO, is a type of special steel primarily used for hot work applications, such as forging dies in high-performance drop hammers.

Here are some key details about this steel grade:

Chemical Composition:

- Carbon ©: 0.57%

- Silicon (Si): 0.25%

- Manganese (Mn): 0.70%

- Sulfur (S): 1.10%

- Chromium (Cr): 0.50%

- Molybdenum (Mo): 1.65%

Mechanical Properties:

- Yield Strength (Rp0.2): ≥ 655 MPa

- Tensile Strength (Rm): ≥ 821 MPa

- Impact Toughness (KV/Ku): 42 J

- Elongation (A): 11%

- Reduction in Cross Section on Fracture (Z): 22%

Applications:

VMO steel is commonly used in the manufacturing of tools and dies that require high strength and toughness, especially in hot working environments.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your VMO Steel experience quality and reliability.

Upgrade your tools and dies with the best in the industry! Contact us today to learn more about how VMO steel can enhance your operations.

Contact us today to learn more!

https://www.viratsteel.in/products/vmo-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 info@viratsteels.com ☎+91 98140-21775

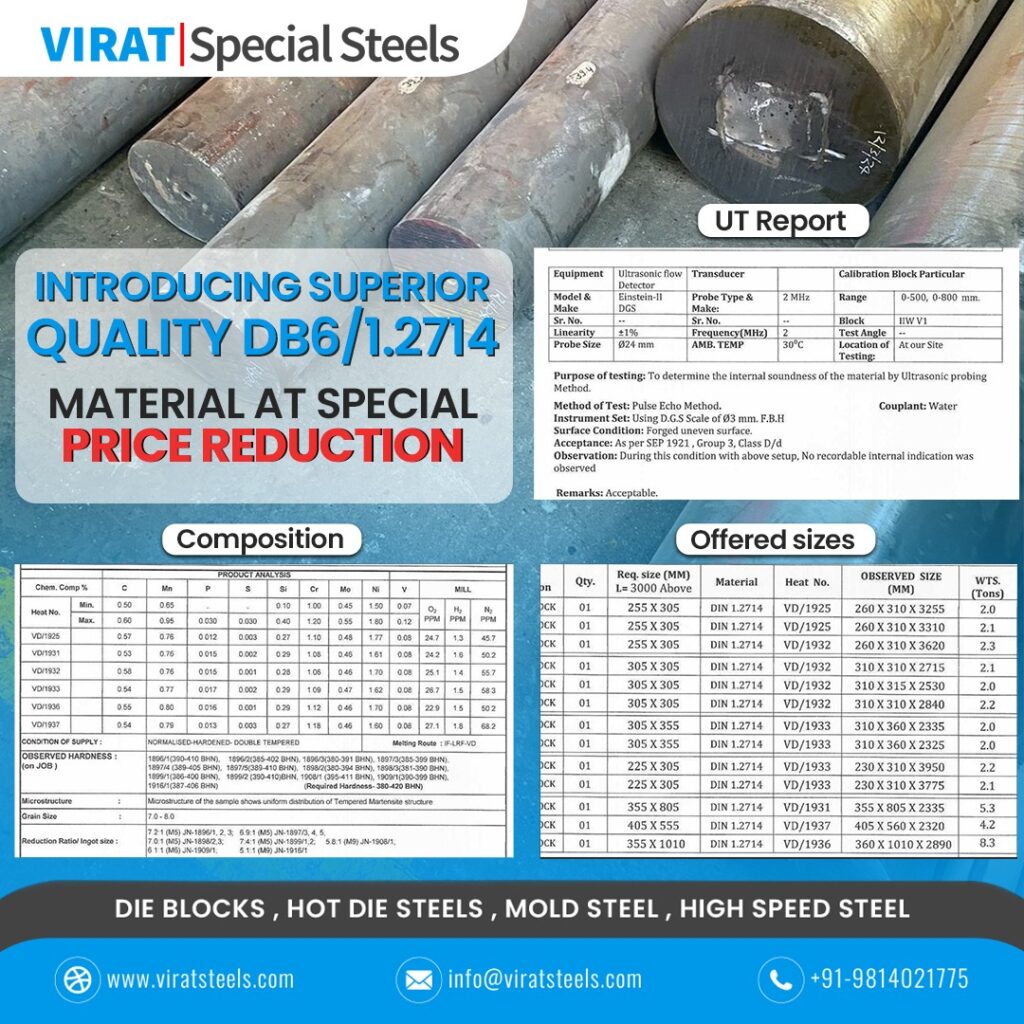

Exciting Offer from VIRAT SPECIAL STEEL!

We’re thrilled to introduce our latest innovation in tool steel – Material 2714 (#DB6), now available at a Special Price Reduction! Experience superior quality with our meticulously crafted steel, designed for high-performance and durability.

Product Specifications:

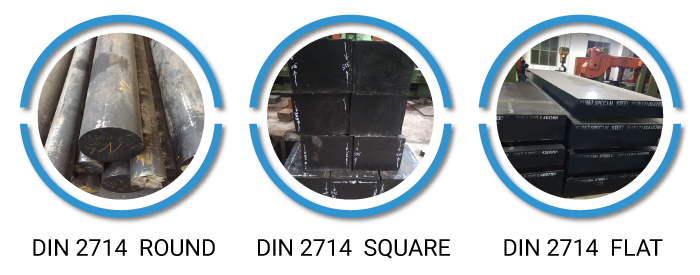

🔘Round Bars: Diameter ranging from 130mm to 610mm, with a precision machined surface for seamless integration into your projects.

🔘Die Blocks: Thickness from 255mm to 455mm, Width from 255mm to 805mm, and Length from 3 to 5 meters – all forged to perfection for robust applications.

Why Choose Material 2714 (DB6)?

Enhanced Wear Resistance, Ideal for close die forgings, ensuring long-lasting tool life. Exceptional Toughness, provides extra durability against impact and stress. High Hardness, achieved through Cr-Ni-Mo-V high graded alloys for peak performance in demanding conditions.

Don’t miss out on this opportunity to elevate your tooling solutions. Contact us now for more details and secure your order!

For more information visit

https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

Email: info@viratsteels.com or Call: +91 98140 21775

Are you looking for Die Steel blocks 2714 in India?

Die steel blocks 2714 could be a great choice for your close die forging applications!

Discover Quality Die Steel with Virat Special Steels Pvt. Limited.

Virat Special Steels indeed offers a variety of tool steels, including Die steel blocks 2714 (DIN 1.2714). We are known for being one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Die steel blocks 2714, also known as DIN 1.2714, is a hot work tool steel with high toughness and wear resistance, which is achieved through a specific composition of chromium, nickel, molybdenum, and vanadium. This grade of steel is characterized by its high tempering resistance and good through-hardening properties, making it particularly impact-resistant and suitable for large hammer and press dies.

Applications:

It’s commonly supplied in a pre-hardened condition and has a typical working hardness range of 360 to 430 BHN (Brinell hardness number). DIN 1.2714 steel is used for various applications, including forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, tools, and more.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels… Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Contact us today to buy the best quality DIN 2714 steel for your tooling needs!

Learn more: https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com

2714 Steel Supplier, Stockiest, Dealer, Trader Importer and Exporter in India!

Steel has transformed the social economic landscape and our affinities with this alloy of iron have become more pronounced with the passage of time. These affinities could be attributed to the salient attributes that steel adores and which make it a preferred choice in multitudes of applications. We can’t even imagine some core activities without steel. No wonder, we have been passionate to gear metallurgical sciences to develop more resonant grades and standards in steel and SS. DIN 2714 is a hot work steel that allows making best forging dies. Metals based manufacturing today forms the basis of many secondary and ancillary enterprises and they rely on steel dies. 2714 steel or DB6 is the considered the best choice for making the toughened dies in different sizes and dimensions.

Why Din 1.2714 / AISI L6 apt for making forging dies and molds?

DB6 steel as a choice for making forging molds and dies is due to various characteristics that it has relative to other metals. It is a hot work steel and therefore allows making the molds that are resilient enough against the hot metals that are put in them. The high level annealing and tempering of DIN 2714 steel causes extreme toughening and hence generates desirable hot working capacity for the forging tasks. The presence of chromium, nickel, molybdenum and vanadium in 2714 Steel alloy generate the extra toughness and very high wear resistance thus making it perfect contender for closed die forgings of entire diversity. The manufacturers of DB6 / Din 2714/ SKT4/ AISI L6 hardened steel dies ensure that the desirable hardness is delivered to the die. Generally, it is in the range of 370 to 410 HB for round type and 355 to 400 HB for flat/square type.

Custom making of DIN 1.2714 / AISI L6 dies necessary!

Customization in the manufacture of 1.2714 steel forging dies is equally important function that determines the efficiency and finesse. Unless the custom development of forging die is done, the attributes of 1.2714 steel could be of no use for the secondary manufacturer that seeks to achieve dimensional functionality and finesse also in its forged products. These forged products could be of diversity ranging from the machine components and tools to toys models and other products. Virat Steels offers to make custom forging dies in high quality DB6 steel and has been serving the diverse sectors of metals based forging.

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of DB6 / DIN 2714 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DB6 die steel is available in flat, square and round shape.

To know about more specific details of DB6 steel ( DIN 1.2714 steel ),

Please visit the websites:

We Provide our Special Steels in All Major Cities India.

#Agra, #Alwar,#Ambala, #Anand, #Bhiwadi, #Dehradun, #Ghaziabad , #Haridwar , #Nagpur, #Ahmedabad, #Pithampur , #Rudrapur #Waluj ,#Visakhapatnam, #Coimbatore, #Nashik, #Mumbai, #Ranchi, #NewDelhi, #Chandigarh, #Bengaluru, #Ernakulam, #Howrah, #Haryana, #Rajkot, #Jaipur, #Surat, #Thiruvananthapuram, #Baroda, #Kolkata, #Indore, #Gurgaon, #Bhopal, #Vadodara, #PimpriChinchwad, #Faridabad, #Noida, #Jamshedpur, #Chennai, #Secunderabad, #NaviMumbai, #Kanpur, #Hyderabad, #Pune, #Thane, #Manesar, #Kundali , #Amaravathi, #Ambattur, #Bangalore, #Belgaum, #Chittoor, #Dindigul, #Mysore, #Nellore, #Kochi, #Mangalore, #Tirupur, #Tuticorin, #Madurai, #AndhraPradesh, #Karnataka, #Puducherry, #Kerala, #TamilNadu, #Telangana, #Salem, #Thanjavur, #Trichy, #Erode, #Vellore, #Ranipet, #Sivakasi, #Karur, #Hosur, #Nagercoil, #Kanchipuram, #Karaikudi, #Neyveli, #Cuddalore, #Kumbakonam, #Thiruvannamalai, #Pollachi, #Rajapalayam, #Gudiyatham, #Pudukottai, #Vaniyambadi, #Ambur, #Nagapattinam, #Trivandrum, #Vijayawada, #Guntur, #Thirupathi, #Nazarathpet, #Kakinada, #Kurnool, #Kadapa, #Nizamabad, #Mahabubnagar, #Karimnagar

What is DB6 and why it’s in high demand in Forging Industries?

Think of different interventions in the developmental history of mankind and economy and you will stumble upon a few that really changed the pace and direction of growth. Steel is one such product and it is rather a much younger sibling of the parent metal iron; while Iron Age cultures synergized the human development in different parts of world. Steel gave the impetus and desirable perfection quotient to generate viability for many innovations.

Why DB6?

DB6 gained prominence as a die making steel alloy that displays high resilience for the hot metal working that is the integral component of metal forgings. Hot molten metal bears extreme temperatures and this also generates possibilities for the wear and tear of the die’s inner surfaces. The exclusive source of DB6 / 2714 / SKT4 / AISI L6 is VIRAT SPECIAL STEELS for wide range of stocks.

High demand for DB6!

DB6 has found high acceptance in the expanding economies like India and also in Europe (nomenclature as DIN2714). VIRAT SPECIAL STEELS PVT. LTD is the largest stockiest of DB6 / 2714 steel grades in world level with multiple size range.

Learn more:

https://www.viratsteels.com/db6.html