Drop Forging Press

now browsing by tag

The Role of DIN 2714 Steel in Forging Industries

The forging industry plays a pivotal role in manufacturing, producing components that form the backbone of various sectors such as automotive, aerospace, construction, and heavy machinery. One material that has emerged as a cornerstone of the forging process is DIN 2714 steel. Renowned for its exceptional properties, DIN 2714 is a hot work tool steel that meets the rigorous demands of forging operations. This blog delves into the characteristics, applications, and benefits of DIN 2714 steel, highlighting its indispensability in the forging industry.

Understanding DIN 2714 Steel

DIN 2714 is a German-standard steel, widely recognized for its high wear resistance, toughness, and thermal stability. It belongs to the family of alloyed steels that exhibit excellent mechanical properties, making it ideal for use in hot forging tools. The composition of DIN 2714 typically includes:

Carbon (C): Contributing to hardness and strength.

Silicon (Si): Enhancing heat resistance.

Manganese (Mn): Improving toughness and hardenability.

Chromium (Cr): Providing corrosion resistance and strength.

Molybdenum (Mo): Increasing high-temperature strength and creep resistance.

This combination of elements gives DIN 2714 its unique ability to withstand extreme operating conditions while maintaining dimensional stability.

Key Properties of DIN 2714 Steel

- High Toughness: With its exceptional toughness, DIN 2714 resists cracking and – chipping, even under heavy loads.

- Excellent Thermal Stability: The steel maintains its mechanical properties at elevated temperatures, making it perfect for hot work applications.

- Wear Resistance: The material can endure prolonged exposure to abrasion, increasing the longevity of forging dies and tools.

- Hardenability: DIN 2714 can achieve a consistent hardness profile, ensuring uniform performance across the material.

Applications in the Forging Industry

DIN 2714 steel’s properties make it indispensable in several forging processes. Some of its primary applications include:

- Forging Dies: The wear resistance and toughness of DIN 2714 make it an excellent choice for dies used in drop forging and upset forging.

- Hot Shear Blades: The steel’s ability to maintain hardness at high temperatures is ideal for cutting hot metal billets.

- Extrusion Tools: DIN 2714’s thermal stability and wear resistance are advantageous in metal extrusion processes.

- Press Tools: These tools require materials that can withstand repeated stress and high impact, making DIN 2714 a preferred choice.

Benefits of Using DIN 2714 Steel

- Increased Tool Life: The superior wear resistance and toughness reduce the frequency of tool replacement, cutting down costs and downtime.

- Improved Efficiency: The steel’s thermal stability allows tools to operate efficiently under high temperatures, enhancing production rates.

- Cost-Effectiveness: Although the initial investment may be higher, the extended tool life and reduced maintenance offset the costs, delivering long-term savings.

- Enhanced Performance: Tools made from DIN 2714 ensure precise and high-quality forging results, meeting stringent industrial requirements.

Conclusion

The forging industry demands materials that can withstand extreme conditions while delivering consistent performance. DIN 2714 steel checks all these boxes, making it a preferred material for manufacturing critical forging tools. By choosing DIN 2714, industries can achieve enhanced productivity, reduced operational costs, and superior product quality.

At Virat Special Steels, we are committed to delivering the highest quality DIN 2714 steel tailored to meet the diverse needs of the forging industry. Partner with us to unlock the potential of this exceptional material and elevate your forging operations to new heights.

FAQ: The Role of DIN 2714 Steel in Forging Industries

1. What is DIN 2714 steel?

DIN 2714 is a German-standard hot work tool steel known for its excellent toughness, wear resistance, and thermal stability. It is widely used in the forging industry for its ability to withstand high temperatures and heavy mechanical loads.

2. What are the key components of DIN 2714 steel?

The primary components of DIN 2714 steel include:

- Carbon (C) for hardness and strength.

- Silicon (Si) for heat resistance.

- Manganese (Mn) for toughness and hardenability.

- Chromium (Cr) for corrosion resistance and strength.

- Molybdenum (Mo) for high-temperature strength.

3. Why is DIN 2714 steel preferred in the forging industry?

DIN 2714 steel is preferred due to its combination of high toughness, wear resistance, thermal stability, and hardenability. These properties make it ideal for manufacturing forging dies, hot shear blades, extrusion tools, and press tools.

4. What applications is DIN 2714 steel suitable for?

DIN 2714 steel is commonly used in:

- Forging dies

- Hot shear blades

- Metal extrusion tools

- Press tools for hot work applications

5. What are the benefits of using DIN 2714 steel in forging?

The key benefits include:

- Prolonged tool life due to high wear resistance

- Improved efficiency in high-temperature operations

- Cost-effectiveness through reduced maintenance and downtime

- Consistent and precise forging results

6. How does DIN 2714 compare with other hot work tool steels?

DIN 2714 stands out for its balanced properties, such as toughness, wear resistance, and heat resistance. It offers an optimal combination of durability and performance, making it a reliable choice for heavy-duty forging tools.

7. Can DIN 2714 steel be customized for specific applications?

Yes, DIN 2714 steel can be heat-treated and machined to meet specific requirements of different forging applications. Working with a trusted supplier ensures customization tailored to your operational needs.

8. What is the typical service life of tools made from DIN 2714 steel?

The service life varies based on the application, maintenance practices, and operating conditions. However, DIN 2714’s durability ensures longer tool life compared to many other materials.

9. How should DIN 2714 steel be maintained to maximize its performance?

Proper maintenance includes regular inspection for wear, timely heat treatment, and ensuring that tools operate within their recommended temperature range. This helps in prolonging the tool’s service life.

10. Where can I source high-quality DIN 2714 steel?

Virat Special Steels is a trusted supplier of premium DIN 2714 steel, offering products tailored to the needs of the forging industry. Contact us to learn more about our offerings and how we can support your business.

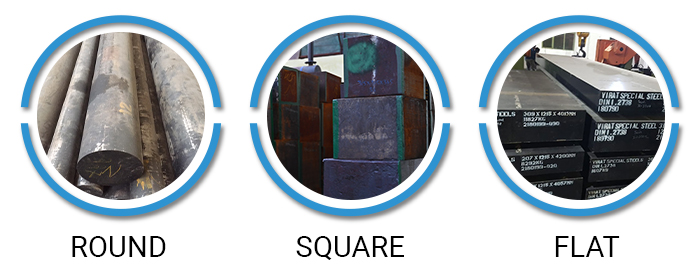

Mode of Supply:

Virat Special Steels is the largest stockiest and supplier of DIN 2714 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2714 die steel is available in flat, square and round shape.

Consult our team who will assist you for DIN 2714 steel query.

https://www.viratsteels.com/din-2714.html

🌐https://www.viratsteels.com 📩info@viratsteels.com 📲+91-98140-21775

How do you choose the right die steel for your forging process?

Choosing the right die steel for your forging process involves several key factors to ensure optimal results and longevity of the dies.

Here are the considerations you should make:

- Strength and Toughness: Select a steel that offers high strength to withstand the stresses of forging without deforming, and toughness to resist cracking under impact.

- Heat Resistance: The steel should maintain its properties at the high temperatures used in forging, preventing premature wear or failure.

- Durability: Consider the wear resistance of the steel, as dies are subject to constant abrasion during the forging process.

- Composition: The alloying elements in the steel, such as chromium, molybdenum, and vanadium, can enhance specific properties like heat resistance and durability.

- Forging Process: The type of forging process (open-die, closed-die, etc.) can influence the choice of steel, as different processes may require different steel properties.

- Work Material: The type, thickness, and hardness of the material being forged will affect the choice of tool steel.

- Production Volume: The number of parts to be produced can also dictate the choice of steel, as high-volume runs may require a steel with greater wear resistance.

- Cost: Balance the cost of the steel with the performance requirements. More expensive steels may offer better performance but could be overkill for less demanding applications.

By carefully considering these factors, you can select a die steel that meets the specific needs of your forging process and contributes to the overall success of your operation. Remember to consult with steel suppliers or specialists if you need more detailed advice tailored to your particular situation.

Are you looking for Drop Forging Press #DieSteelH13?

H13 tool steel is a widely used die steel for drop forging presses, known for its excellent properties such as high toughness, thermal fatigue resistance, and high hardenability. It’s particularly well-suited for applications that require resistance to thermal shock and cracking, making it ideal for the harsh conditions of drop forging.

If you’re in need of H13 tool steel for your drop forging press, Virat Special Steels offers a comprehensive range of H13 steel in various shapes and sizes to meet your requirements. With options in flat, square, and round bar forms, they can cater to any specific needs you might have.

For personalized assistance and to address any queries regarding H13 steel, don’t hesitate to reach out to the Virat Special Steels team. They are equipped to provide you with expert guidance and support.

Any further queries feel free to contact us :

☎+91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com