July, 2022

now browsing by month

H13 hot work steels for Dies and Moulds

H13 ( DIN 2344 ) hot work steel has found profound resonance in the manufacturing industry that readily relies on it for its dies and moulds requirements. This steel grade has been specifically developed with the prime objective of letting it sustain the demands that are intrinsic to the production of molded products. Virat Special Steels is the leading Merchant, importer and exporter of H13 steels and offers a diversified choice as per the suitability of the client.

Why H13 is the preferred choice?

The physical characteristics of H13 steel are derived from the distinct make and composition of it. The concentration and ratios of different components need to be ensured as required so that the desirable attributes are secured. Failing the same, the molding dies may never deliver as per standards. Apart from maintaining specific composition, other processes are also adhered to like annealing and tempering of the steel. H13 steel is forged at 1079 degree centigrade while the minimum forging threshold prescribed for it is 898 degree centigrade. Annealing is done at 871 degree centigrade and tempering of it is performed in the thermal range of 538 – 649 degree centigrade. These processes ensure that high tensile strength and elasticity is generated through the micro arraying of the components in the most even manner.

In fact micro structure of H13 steel is directly responsible for the characteristics that make it the preferred choice as for making hot injection molding, Forging, Extrusion dies etc. The thermal resistance that it offers as regards temperature variation during the injection of material is much superior as compared to other tools and dies steels in the hot work steel category. Virat Special Steels is a pioneer in the manufacture of H13 steel based products including all kinds of dies and moulds and ensures the optimized value by maintaining strict standards.

High applicative value of H13

With the molding and dies applications growing multifold in the manufacturing economy around the world, H13 has emerged as the top choice. Not only for the hot working but it is also being actively used as cold working steel for tools and moulds. However, it is its capacity to withstand the wear and thermal induced corrosion that 2344 steel has felt wider acceptance in the hot injection molding and tooling applications in manufacturing enterprises. It allows long term use with little maintenance while the finesse and polishing potential that is carries for the finished product is of high standard too. This directly impacts the cost of the final product to be sent in market and ensures economy in production.

Further the ability to offer custom H13 products/moulds can increase productivity for companies that are engaged in making specialized products. www.h13steel.in / Viratsteels.com is a specialty manufacturer of H13 steels and offers highly versatile customized products to Indian and international clients.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website www.h13steel.in / www.viratsteels.com

Virat Special Steels are largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

What is PLASTIC MOULD STEEL?

Plastic Mould Steels are characterised by good dimensional stability during heating, good polishability, high impact strength and good wear characteristics. This steel is an alloy of iron and nickel with a minimum of 10% carbon. It is used to make plastic moulds and dies, as well as castings for various purposes.

Plastic mould steel has a low coefficient of expansion, which makes it ideal for use in the cold environment of a plastic mould. It also has good machinability. The alloy has good weldability and can be easily worked without cracking due to its high strength.

Plastic mould steel is one of the most common materials used in manufacturing. This type of steel is commonly used to make products that are at risk of being damaged or destroyed by heat, such as food cans, drink bottles and food packaging.

Plastic mould steel is not just a good material for these products, but it can also be used for other purposes including: furniture construction, fencing, car parts and industrial components.

Plastic Mould Steel is an alloy of carbon, silicon, manganese and phosphorous. It has a high strength and ductility, with good fracture toughness properties. The addition of phosphorus gives it very good resistance to cold working. This material is usually used in complex machine parts where precision is required. It can be cast or forged.

Plastic Mould Steel is a type of steel that is used in many manufacturing processes. It is also used to make rubber and plastic moulds, which are then used to create products such as tools and toys. Plastic Mould Steel has many advantages over other types of steel. It can be formed into shapes that are difficult or impossible to achieve with other types of steel, and it can be used in high-temperature applications without being damaged by harsh conditions or chemicals.

Plastic moulds, mould frames for plastic moulds and pressure casting moulds and recipient sleeves.

Generally, few steel industries use these special steels from different mechanical engineering & tool manufacturers. And used for various large-size mirror plastic mould, precision plastic mould, like car accessories, home appliances, electronic equipment plastic mould.

Tempered and Pre-hardened is done to 1000Mpa. Whenever for plastic processing mould carrier large moulds ( over 400mm thickness) is used. Pre-hardened plastic mould steels are widely used for manufacturing mould for plastic.

High grade mould base for mirror surface & EDM requirement, rubber moulds, Injection moulds for bottle crates, TV sets housing fames, refrigerator doors, bucket and automobile related compartments, electrical and audio visual related compartments and etc.

PROPERTIES & CHARACTERISTICS:

- Wear Resistance

- Mould Frames

- Machine Tool Engineering

- Die Casting Industry

- Mould Parts

- Preform Dies

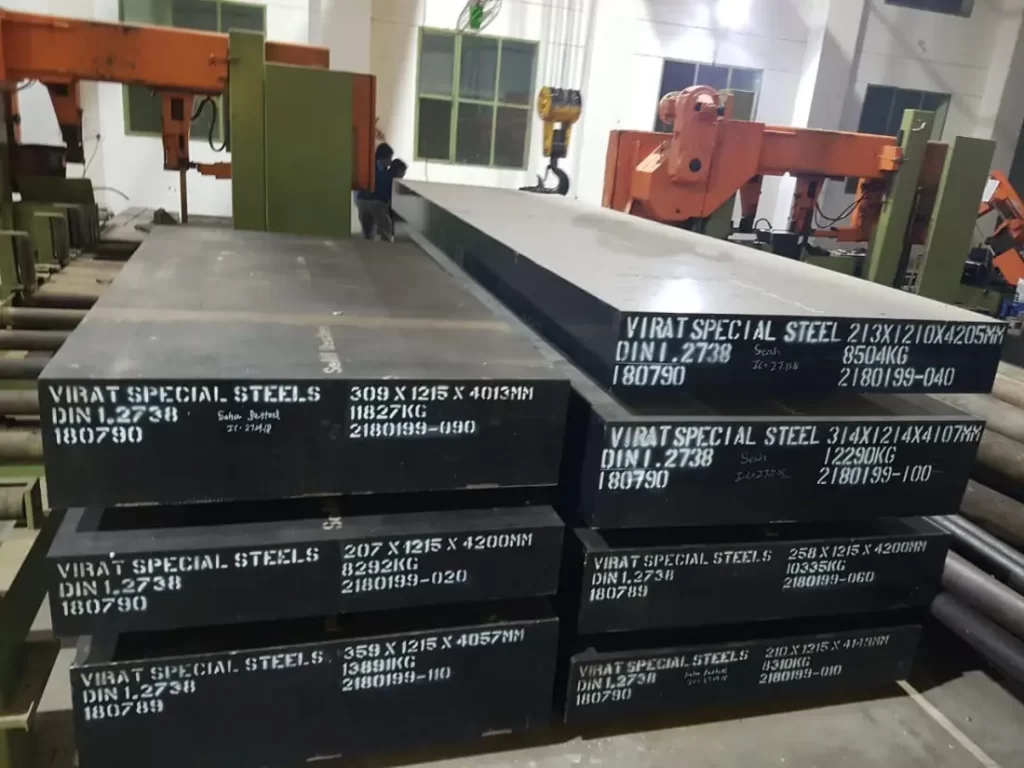

Virat Special Steels is the largest Supplier & Stockiest of Plastic Mould Steels.

Learn More:

https://www.viratsteels.com/plastic-mould-steel.html

What is DB6 and why it’s in high demand in Forging Industries?

Think of different interventions in the developmental history of mankind and economy and you will stumble upon a few that really changed the pace and direction of growth. Steel is one such product and it is rather a much younger sibling of the parent metal iron; while Iron Age cultures synergized the human development in different parts of world. Steel gave the impetus and desirable perfection quotient to generate viability for many innovations.

Why DB6?

DB6 gained prominence as a die making steel alloy that displays high resilience for the hot metal working that is the integral component of metal forgings. Hot molten metal bears extreme temperatures and this also generates possibilities for the wear and tear of the die’s inner surfaces. The exclusive source of DB6 / 2714 / SKT4 / AISI L6 is VIRAT SPECIAL STEELS for wide range of stocks.

High demand for DB6!

DB6 has found high acceptance in the expanding economies like India and also in Europe (nomenclature as DIN2714). VIRAT SPECIAL STEELS PVT. LTD is the largest stockiest of DB6 / 2714 steel grades in world level with multiple size range.

Learn more:

https://www.viratsteels.com/db6.html