Drop forging die 2714

now browsing by category

Exploring the Versatility of Die Steel 2714 in Industrial Applications!

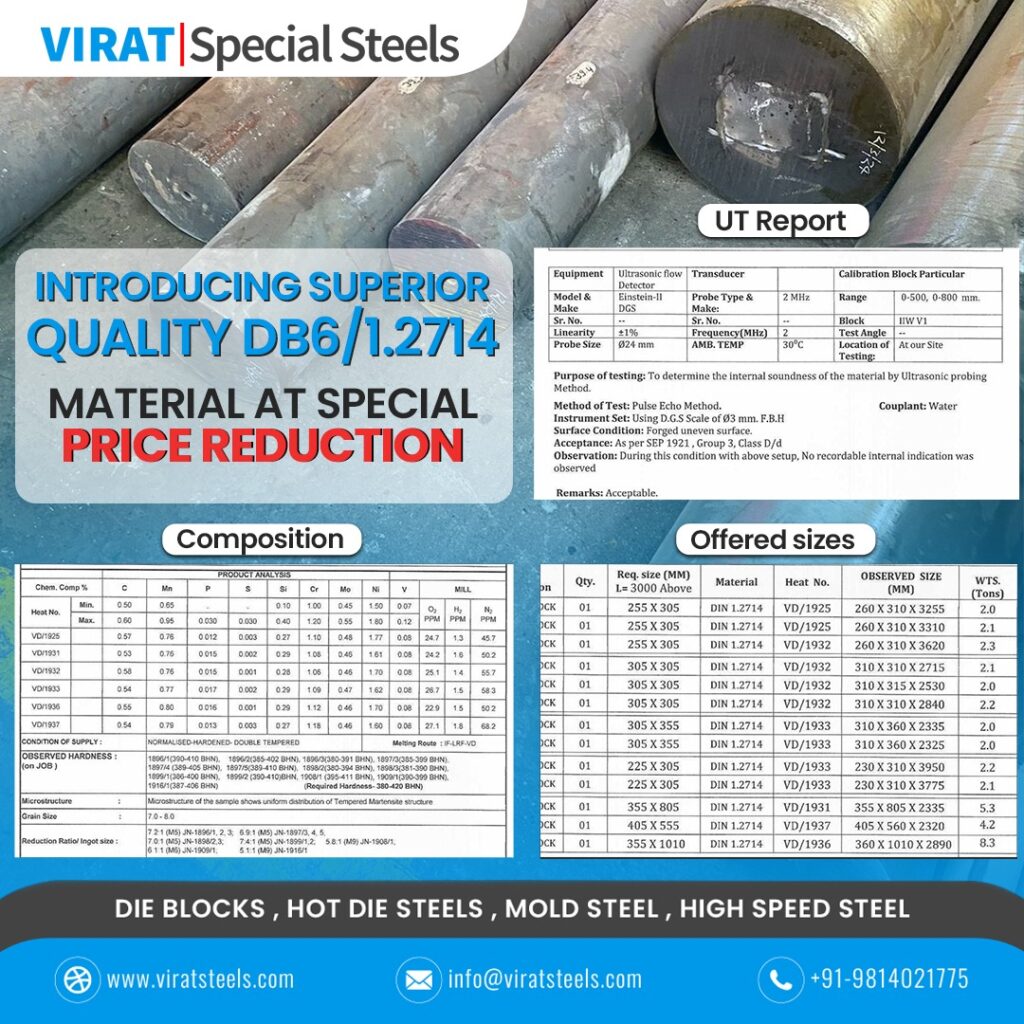

Die steel blocks 2714, also known as DIN 1.2714, represent a significant advancement in the tool steel category, offering a combination of toughness and wear resistance that is essential for the rigorous demands of close die forging applications. This particular grade of steel is engineered through a precise alloying process that incorporates elements such as chromium, nickel, molybdenum, and vanadium, which collectively contribute to its outstanding properties.

The high tempering resistance and excellent through-hardening capabilities of DIN 1.2714 make it an ideal choice for manufacturing large hammer and press dies, which are subjected to extreme impact and stress. The steel’s ability to withstand such conditions without compromising its structural integrity is a testament to its superior quality.

In terms of applications, the versatility of die steel blocks 2714 is evident. Supplied typically in a pre-hardened state, it exhibits a working hardness range of 360 to 430 BHN, making it suitable for a wide array of tools and components. These include forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, and many other specialized tools that are integral to various industrial processes.

Another noteworthy characteristic of DIN 1.2714 steel is its thermal properties. Good thermal conductivity and a favorable coefficient of thermal expansion are crucial for materials used in high-temperature environments, as they ensure consistent performance and longevity of the tools made from this steel.

Virat Special Steels Pvt. Limited, based in Gurgaon, Haryana, and Ludhiana, Punjab, India, stands out as a prominent supplier in this sector. As one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels, the company boasts an extensive inventory that caters to diverse industrial needs.

For businesses looking to enhance their manufacturing capabilities with high-quality die steel, Virat Special Steels Pvt. Limited offers a reliable source for obtaining DIN 1.2714. With a commitment to maintaining a substantial stock and providing expert guidance, the company ensures that clients have access to the best materials for their specific requirements.

In conclusion, die steel blocks 2714 stand as a robust and adaptable material that can significantly benefit industries reliant on forging and tooling. Its combination of durability, resistance, and thermal stability makes it a valuable asset for any operation aiming to achieve excellence in manufacturing and production. For inquiries and requirements, Virat Special Steels Pvt. Limited invites potential clients to reach out and explore the possibilities that this exceptional steel grade has to offer.

Contact us today to buy the best quality DIN 2714 steel for your tooling needs!

Learn more:

https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/📲+91-98140-21775 📩 info@viratsteels.com

Exploring the Versatility of DIN 2714 Steel in India’s Forging Industry!

The forging industry in India has been a backbone of the manufacturing sector, contributing significantly to the economy. A key player in this industry is the specialized steel used for die blocks, particularly DIN 1.2714, also known as DB6. This hot work tool steel is renowned for its high hardness, wear resistance, and strength, coupled with sufficient toughness to withstand the rigorous demands of forging.

DIN 1.2714 steel is characterized by its excellent through-hardening properties, which are imparted by the presence of alloying elements such as chromium, nickel, molybdenum, and vanadium. These elements not only enhance the steel’s hardness but also contribute to its wear resistance, making it an ideal choice for the production of large dies with heavy embossing used in drop or hammer forging.

One of the largest suppliers of this versatile steel in India is Virat Special Steels, which has established itself as a premier stockist, importer, and exporter of DIN 1.2714 hot die block or hot work steel. Virat Special Steels is the world largest Supplier, Stockist, Importer and Exporter of DIN 1.2714 (DB6) Hot Die Block or Hot Work Steel. The company caters to the diverse needs of the forging industry by providing this steel in various conditions, including hard, quenched, tempered, and even annealed for special cases. The working hardness of this steel typically ranges between 360-430 BHN, striking a balance between durability and machinability.

The popularity of DIN 1.2714 steel in the Indian market is a testament to its adaptability and performance in challenging environments. Its application extends beyond traditional forging and encompasses various industries where high-stress resistance and longevity are paramount.

For those interested in learning more about DIN 1.2714 steel or seeking to procure it for their manufacturing processes, resources are available that provide detailed information on its properties, applications, and availability. As the forging industry continues to evolve, the role of specialized steels like DIN 1.2714 will undoubtedly become even more crucial, driving innovation and efficiency in manufacturing.

For more information on DIN 1.2714 steel and its applications within the forging industry, visiting a dedicated supplier’s website can offer valuable insights and opportunities for procurement.

Know more about DIN 1.2714 Steel or want to DIN 1.2714 Steel

Just visit – www.viratsteels.com

Get your quotation call Us +91- 9814021775

What materials are used in pressure die casting?

Looking for quality Tool & Die Steels for your Pressure Die Casting Industry?

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry. Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21).

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more :

https://www.viratsteels.com/hot-work-steel.html

Any queries feel free to contact us : info@viratsteels.com or

Call on mobile number +91-98140 21775

Exploring Tool and Die Steel Supplier in Faridabad?

When it comes to tool and die steel suppliers in Faridabad, there are several options to explore. Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Faridabad!

Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made solutions. With state-of-the-art plants in #Gurugram and #Ludhiana, they have established a strong distribution network across India.

Available Grades:

- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Encompasses DIN 2343, 2344, AISI H11, and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Comprising DIN 2379, 2080, AISI D2, and D3.

- Alloy Steels, EN-Series, and More.

Quality Assurance and Examination:

Virat Special Steels has an impressive quality assurance facility, including chemical tests, spectrometry, ultrasonic examinations, and hardness testing. This ensures optimal steel selection for specific applications and cost optimization in the long run.

Make In INDIA:

They offer competitive prices, top-notch quality, and prompt service, positioning themselves as a reliable “Make In INDIA” choice for their customers.

For more information, you can explore their details:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-Faridabad/

Remember to explore this suppliers and find the right fit for your specific tool and die steel requirements in Faridabad!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📧 info@viratsteels.com 📞 +91-98140 21775

Understanding Steel and Carbon Steel a Comprehensive Guide!

Steel and carbon steel are two materials that are integral to modern construction and manufacturing. While they may seem similar, there are distinct differences that make each suitable for specific applications.

Steel:

Steel is an alloy made primarily of iron and carbon, but it can also contain other elements like silicon, manganese, chromium, nickel, and molybdenum. These elements are added to give steel certain properties, such as increased strength, ductility, and resistance to corrosion. Steel’s versatility makes it ideal for a wide range of uses, from building infrastructure to manufacturing automobiles and airplane parts.

Carbon Steel:

On the other hand, carbon steel is a type of steel where carbon is the main alloying element. The amount of carbon can vary, resulting in different classifications such as mild, medium, high, and ultra-high carbon steel. These classifications affect the steel’s hardness, strength, and ductility. For instance, high carbon steel is extremely hard and strong, making it suitable for cutting tools and blades. However, it is less ductile, which means it is more brittle and can break under high stress.

Choosing the right type of steel is crucial for any project.

Factors to consider include the environment in which the material will be used, the desired durability, and the need for flexibility. For example, in corrosive environments, a non-corrosive type of steel would be necessary, while applications requiring a lot of shaping or bending would benefit from a more ductile steel.

Virat Special Steels stands out as a reputable supplier of tool steel, die steel, and mold steel in India. They offer steel in various sizes and shapes to meet diverse customer needs. With facilities in Gurgaon, Haryana, and Ludhiana, Punjab, Virat Special Steels is well-positioned to provide high-quality steel for a variety of applications.

Product List:

- DIE STEELS ( HH 370 – 410 BHN ) DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

In conclusion, whether you’re involved in construction, manufacturing, or any industry that relies on steel, understanding the differences between steel and carbon steel is essential. By selecting the appropriate type of steel, you can ensure the longevity and success of your projects. Remember, when it comes to steel, making an informed choice is key, and Virat Special Steels is there to guide you through the process.

Are you looking for Die Steel blocks 2714 in India?

Die steel blocks 2714 could be a great choice for your close die forging applications! … Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED , INDIA.

Die Steel blocks 2714 Supplier in India – Virat Special Steels

Virat Special Steels indeed offers a variety of tool steels, including #DieSteelBlocks (DIN 1.2714). We are known for being one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Die steel blocks 2714, also known as DIN 1.2714, is a hot work tool steel with high toughness and wear resistance, which is achieved through a specific composition of chromium, nickel, molybdenum, and vanadium. This grade of steel is characterized by its high tempering resistance and good through-hardening properties, making it particularly impact-resistant and suitable for large hammer and press dies.

Applications:

It’s commonly supplied in a pre-hardened condition and has a typical working hardness range of 360 to 430 BHN (Brinell hardness number). DIN 1.2714 steel is used for various applications, including forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, tools, and more.

DIN 1.2714 steel is also known for its good thermal conductivity and coefficient of thermal expansion, which are critical properties for materials used in high-temperature environments.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels… Based in Gurgaon (Haryana) & Ludhiana (Punjab) India.

Contact us today to buy the best quality DIN 2714 steel for your tooling needs!

Learn more:

https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📲+91-98140-21775 📩 info@viratsteels.com

Steel – The Backbone of Modern Industries!

Steel, an alloy of iron and carbon, is a cornerstone of the modern industrial world, thanks to its remarkable properties. Its strength, versatility, and recyclability make it an indispensable material in construction, transportation, and manufacturing industries.

Choosing the Right Steel – Virat Special Steels

The Evolution of Steel

The journey of steel is a testament to human ingenuity. From the early days of blacksmiths forging weapons and tools to the sophisticated production methods of today, steel has evolved significantly. The introduction of the Bessemer process in the 19th century marked a turning point, allowing mass production of steel and fueling the Industrial Revolution.

Strength and Versatility

Steel’s strength is derived from its microstructure, which can be altered through heat treatment and the addition of other elements like chromium, nickel, and molybdenum. These modifications lead to over 3,500 different grades of steel, each tailored for specific applications. The versatility of steel is evident in its various forms, from the stainless steel in kitchen appliances to the high-tensile steel in skyscrapers.

Sustainability and Innovation

Steel is also one of the most recycled materials on the planet. Its magnetic properties make it easy to separate from waste streams, ensuring that it can be melted down and repurposed indefinitely. Innovations in steel production, such as electric arc furnaces, have made the process more energy-efficient and environmentally friendly.

The Future of Steel

As research continues, the potential for even stronger and more resilient steel alloys exists. The industry is exploring new compositions and manufacturing techniques to enhance steel’s performance further. With approximately 75% of modern steels developed in the last two decades, the future promises even more advanced materials.

Choosing the Right Steel

For those involved in manufacturing or construction, selecting the right grade of steel is crucial. Factors like weldability, toughness, and corrosion resistance must be considered to ensure the longevity and safety of the final product.

Virat Steel: Your Partner in Steel Supply

For those seeking steel solutions in India and beyond, Virat Steel offers a wealth of expertise and a wide range of products. With a commitment to quality and customer service, Virat Steel is poised to meet the demands of various industries.

Looking for Steel in every Indian city and abroad ?

Learn More About steel at Virat Steel & its Supply – https://www.viratsteel.in/special-steel-supply-networks/

Now that you’re knowledgeable about the strongest metals around, you’re one step closer to choosing the right metal for your next project.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

To explore the possibilities of steel and find the perfect match for your project, reach out to Virat Steel. Their team is ready to address your queries and provide the support you need to make informed decisions about steel.

Contact Virat Steel at 98140-21775 or visit their website to discover more about their offerings and how they can contribute to your next project’s success. Steel is not just a material; it’s the foundation upon which modern civilization is built.

Precision Forging Starts with DIN 2714 – Trust Virat Steels!

The world of manufacturing is ever-evolving, and precision forging is at the forefront of this industrial revolution. A key player in this domain is DIN 2714 tool steel, also known as DB6 or AISI L6. This grade of steel is renowned for its exceptional properties, making it a top recommendation for Close Die Forgings. Let’s delve into the characteristics that make DIN 2714 the go-to material for high-stress applications.

Drop forging die 2714

Grade Brief:

DIN 1.2714 is a testament to engineering excellence, showcasing high wear-resistance, extra toughness, and remarkable hardness. These traits are attributed to its Cr-Ni-Mo-V high-graded alloy composition. Typically utilized in a pre-hardened state, it offers a standard hardness ranging from 360 to 430 BHN, ensuring durability and longevity in its applications.

Applications:

The versatility of DIN 2714 is evident in its wide range of applications. It’s the material of choice for Close Die Forgings, where precision is paramount. The automotive industry benefits from its resilience, while the aerospace sector values its reliability. In metalworking and tool and die manufacturing, DIN 2714’s properties are indispensable for creating high-quality, durable tools and components.

Mechanical Properties:

DIN 2714′s mechanical properties are impressive, with tensile strength ranging from 1000-1400 MPa and a yield strength of 1045 MPa. Its elongation rate of 15%-20% is coupled with impact toughness of 20 J/cm² – 25 J/cm² and a hardness of 50-55 HRC. With a compressive strength of 2500 MPa and a modulus of elasticity of 205 GPa, it stands as a robust option for demanding industrial tasks.

Physical Properties:

The coefficient of thermal expansion (20-600°C) stands at 14.3 x 10⁻⁶ m/(m·K), and its thermal conductivity at 20°C is 36.0 W/(m·K). These physical properties highlight DIN 2714’s ability to withstand varying temperatures, a crucial factor in forging and other high-temperature processes.

Virat Special Steels takes pride in providing DIN 2714 tool steel in various forms, including flat, square, and round bars. Catering to specific industry needs, they offer this steel in pre-hardened, quenched and tempered, or annealed conditions. Their commitment to quality and customer satisfaction is evident in their open invitation for consultations on DIN 2714 steel.

In conclusion, DIN 2714 stands as a pillar of strength and reliability in the world of precision forging. Its comprehensive properties and adaptable applications make it a valuable asset for industries striving for excellence. Trust in Virat Steels to deliver the best in DIN 2714 tool steel, and propel your manufacturing processes to new heights.