Virat Special Steel

now browsing by category

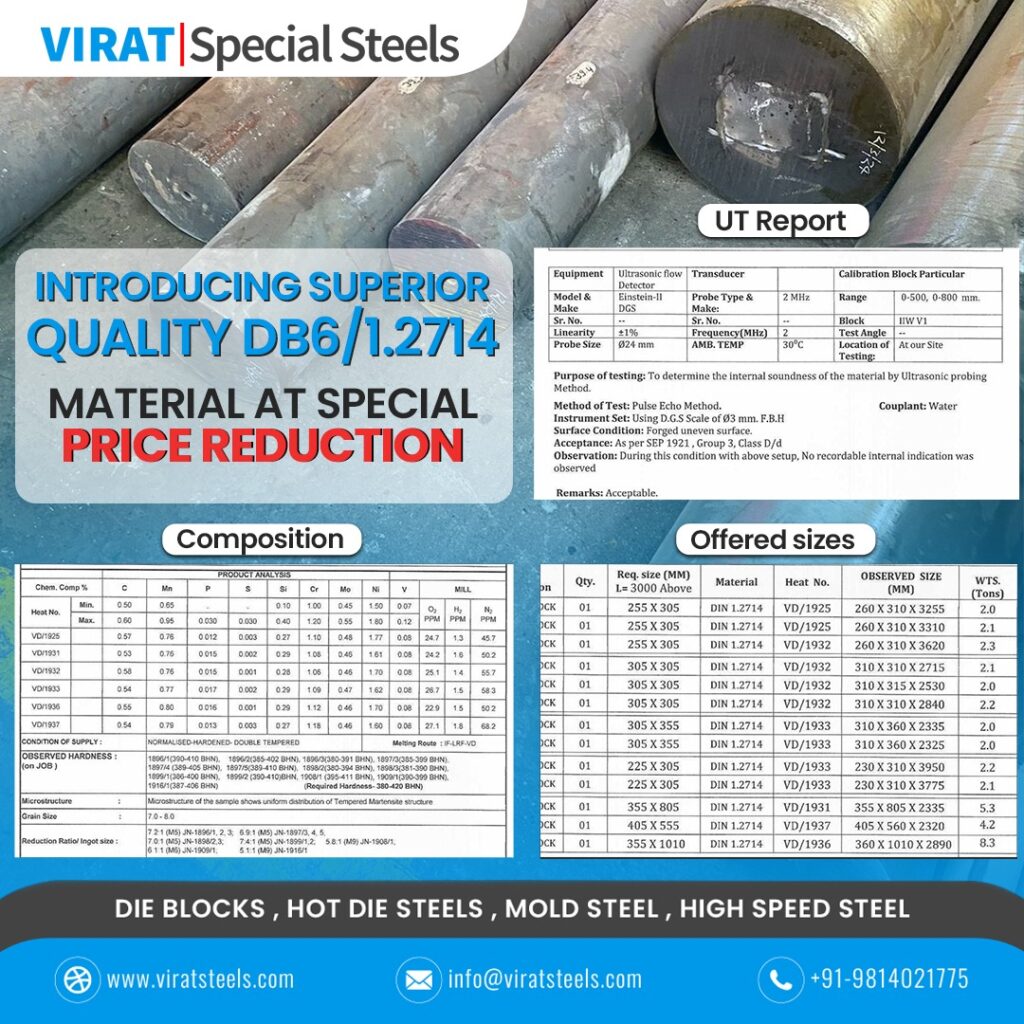

Are you looking for Die Steel blocks 2714 in India?

Die steel blocks 2714 could be a great choice for your close die forging applications! … Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED , INDIA.

Die Steel blocks 2714 Supplier in India – Virat Special Steels

Virat Special Steels indeed offers a variety of tool steels, including #DieSteelBlocks (DIN 1.2714). We are known for being one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Die steel blocks 2714, also known as DIN 1.2714, is a hot work tool steel with high toughness and wear resistance, which is achieved through a specific composition of chromium, nickel, molybdenum, and vanadium. This grade of steel is characterized by its high tempering resistance and good through-hardening properties, making it particularly impact-resistant and suitable for large hammer and press dies.

Applications:

It’s commonly supplied in a pre-hardened condition and has a typical working hardness range of 360 to 430 BHN (Brinell hardness number). DIN 1.2714 steel is used for various applications, including forging dies, die molds, shoe blocks, die holders, piston rods, bolster, cranks, cassettes, plastic molds, shearing blades, tools, and more.

DIN 1.2714 steel is also known for its good thermal conductivity and coefficient of thermal expansion, which are critical properties for materials used in high-temperature environments.

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels… Based in Gurgaon (Haryana) & Ludhiana (Punjab) India.

Contact us today to buy the best quality DIN 2714 steel for your tooling needs!

Learn more:

https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📲+91-98140-21775 📩 info@viratsteels.com

Are you looking for Tool and Die Steel Supplier in Dehradun?

Dehradun, the capital city of the Indian state of Uttarakhand, is not only a major educational and research hub but also has a presence in the steel industry. Specifically, it houses industries that manufacture and supply various steel products, including tool steel and die steel. One notable company in this sector is Virat Special Steels Pvt. Limited, which deals in a wide range of steel types such as tool steel, die steel, plastic mold steel, high speed steel, and alloy steel.

They offer value-added services like material machining, cut pieces, and tailor-made material. Additionally, they provide metallurgical advice and quality assurance, with a fully equipped quality assurance and process examination facility. This includes a laboratory for steel analysis through chemical tests and spectrometry, ultrasonic examination, and hardness testing on various scales.

For those interested in the steel industry in Dehradun, particularly in tool and die steel, Virat Special Steels Pvt. Limited seems to be a prominent supplier with a comprehensive range of services and products.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

They also have a strong distribution network across India.

You can visit their website:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-dehradun/

Any further queries feel free to contact us :

🌐https://viratsteels.com 📨 info@viratsteels.com 📞 +91 098140-21775

Steel – The Backbone of Modern Industries!

Steel, an alloy of iron and carbon, is a cornerstone of the modern industrial world, thanks to its remarkable properties. Its strength, versatility, and recyclability make it an indispensable material in construction, transportation, and manufacturing industries.

Choosing the Right Steel – Virat Special Steels

The Evolution of Steel

The journey of steel is a testament to human ingenuity. From the early days of blacksmiths forging weapons and tools to the sophisticated production methods of today, steel has evolved significantly. The introduction of the Bessemer process in the 19th century marked a turning point, allowing mass production of steel and fueling the Industrial Revolution.

Strength and Versatility

Steel’s strength is derived from its microstructure, which can be altered through heat treatment and the addition of other elements like chromium, nickel, and molybdenum. These modifications lead to over 3,500 different grades of steel, each tailored for specific applications. The versatility of steel is evident in its various forms, from the stainless steel in kitchen appliances to the high-tensile steel in skyscrapers.

Sustainability and Innovation

Steel is also one of the most recycled materials on the planet. Its magnetic properties make it easy to separate from waste streams, ensuring that it can be melted down and repurposed indefinitely. Innovations in steel production, such as electric arc furnaces, have made the process more energy-efficient and environmentally friendly.

The Future of Steel

As research continues, the potential for even stronger and more resilient steel alloys exists. The industry is exploring new compositions and manufacturing techniques to enhance steel’s performance further. With approximately 75% of modern steels developed in the last two decades, the future promises even more advanced materials.

Choosing the Right Steel

For those involved in manufacturing or construction, selecting the right grade of steel is crucial. Factors like weldability, toughness, and corrosion resistance must be considered to ensure the longevity and safety of the final product.

Virat Steel: Your Partner in Steel Supply

For those seeking steel solutions in India and beyond, Virat Steel offers a wealth of expertise and a wide range of products. With a commitment to quality and customer service, Virat Steel is poised to meet the demands of various industries.

Looking for Steel in every Indian city and abroad ?

Learn More About steel at Virat Steel & its Supply – https://www.viratsteel.in/special-steel-supply-networks/

Now that you’re knowledgeable about the strongest metals around, you’re one step closer to choosing the right metal for your next project.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

To explore the possibilities of steel and find the perfect match for your project, reach out to Virat Steel. Their team is ready to address your queries and provide the support you need to make informed decisions about steel.

Contact Virat Steel at 98140-21775 or visit their website to discover more about their offerings and how they can contribute to your next project’s success. Steel is not just a material; it’s the foundation upon which modern civilization is built.

Is H13 Tool Steel better than M2 Tool Steel?

H13 tool steel and M2 tool steel are two prominent members of the tool steel family, each offering unique characteristics and suitability for specific applications.

H13 is a chromium-based hot-work tool steel, possess notable amounts of chromium, molybdenum, and vanadium in its composition. This blend provides exceptional toughness, making it an excellent choice for applications requiring durability in high-temperature environments such as die casting and forging.

On the other hand, M2, often referred to as high-speed steel, is a tungsten-molybdenum high-speed tool steel. With significant tungsten and molybdenum content, along with other elements like chromium and vanadium, M2 exhibits remarkable hardness and an ability to maintain its cutting edge even at elevated temperatures. This quality renders it ideal for cutting tools like: drills, taps, and milling cutters that demand endurance in high-speed cutting operations.

In its hardened state, H13 steel shows greater fracture toughness compared to M2 steel, while the M2 possesses higher hardness.

If you need more information or advice , please explore with Virat Special Steels , a leading supplier of tool steels in India and abroad can provide you with high-quality #H13 and #M2 steels in various forms and sizes, as well as heat treatment and machining services.

If you’re looking to purchase H13 and #M2 steels or have specific questions about their products, it’s best to directly visit their official website or contact them for details.

Give us a call today at 98140-21775 and visit our website : www.viratsteels.com to learn more about our products, service and more .

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us :

🌐https://viratsteels.com 📨 info@viratsteels.com 📞 +91 098140-21775

Precision Forging Starts with DIN 2714 – Trust Virat Steels!

The world of manufacturing is ever-evolving, and precision forging is at the forefront of this industrial revolution. A key player in this domain is DIN 2714 tool steel, also known as DB6 or AISI L6. This grade of steel is renowned for its exceptional properties, making it a top recommendation for Close Die Forgings. Let’s delve into the characteristics that make DIN 2714 the go-to material for high-stress applications.

Drop forging die 2714

Grade Brief:

DIN 1.2714 is a testament to engineering excellence, showcasing high wear-resistance, extra toughness, and remarkable hardness. These traits are attributed to its Cr-Ni-Mo-V high-graded alloy composition. Typically utilized in a pre-hardened state, it offers a standard hardness ranging from 360 to 430 BHN, ensuring durability and longevity in its applications.

Applications:

The versatility of DIN 2714 is evident in its wide range of applications. It’s the material of choice for Close Die Forgings, where precision is paramount. The automotive industry benefits from its resilience, while the aerospace sector values its reliability. In metalworking and tool and die manufacturing, DIN 2714’s properties are indispensable for creating high-quality, durable tools and components.

Mechanical Properties:

DIN 2714′s mechanical properties are impressive, with tensile strength ranging from 1000-1400 MPa and a yield strength of 1045 MPa. Its elongation rate of 15%-20% is coupled with impact toughness of 20 J/cm² – 25 J/cm² and a hardness of 50-55 HRC. With a compressive strength of 2500 MPa and a modulus of elasticity of 205 GPa, it stands as a robust option for demanding industrial tasks.

Physical Properties:

The coefficient of thermal expansion (20-600°C) stands at 14.3 x 10⁻⁶ m/(m·K), and its thermal conductivity at 20°C is 36.0 W/(m·K). These physical properties highlight DIN 2714’s ability to withstand varying temperatures, a crucial factor in forging and other high-temperature processes.

Virat Special Steels takes pride in providing DIN 2714 tool steel in various forms, including flat, square, and round bars. Catering to specific industry needs, they offer this steel in pre-hardened, quenched and tempered, or annealed conditions. Their commitment to quality and customer satisfaction is evident in their open invitation for consultations on DIN 2714 steel.

In conclusion, DIN 2714 stands as a pillar of strength and reliability in the world of precision forging. Its comprehensive properties and adaptable applications make it a valuable asset for industries striving for excellence. Trust in Virat Steels to deliver the best in DIN 2714 tool steel, and propel your manufacturing processes to new heights.

Exploring the Role of Special Steels in NOIDA’s Industrial Growth!

NOIDA and Greater NOIDA, adjoining the Indian capital of Delhi, are bustling industrial hubs that have witnessed significant growth over the past few decades. These twin cities in Uttar Pradesh are home to a diverse range of manufacturers, from large automobile producers to small-scale engineering units. The backbone of this industrial diversity is the specialized materials that fuel innovation and efficiency, particularly special steels.

Special Steels Supplier in NOIDA

Special steels are a cornerstone for a vast array of manufacturing processes. They are integral to the production of heavy vehicles, tractors, and automobile transmission parts. Moreover, they play a critical role in general engineering and the manufacture of precision components such as ball and roller bearings, various types of gears, camshafts, universal joints, driving pinions, link components, axles, arbours, gear shafts, and spinning tools.

The proximity of Gurgaon to NOIDA and Greater NOIDA is of strategic importance. Gurgaon, known for its rapid urbanization and commercial development, is also the headquarters of Virat Special Steels. This company stands out as one of India’s premier suppliers of Tool Steel, Die Steel, and Mould Steel. Their extensive inventory includes nearly every grade of special steel available, catering to the nuanced needs of the region’s manufacturers.

The special steels supplied by Virat Special Steels are engineered to meet specific industrial requirements. For instance, case-hardened steel, known for its low carbon content, offers excellent wear resistance due to its high surface hardness. This feature, coupled with a small grain size, ensures that the steel has high ductility and fatigue strength. Nitrided steels are another category that boasts a combination of wear resistance and surface fatigue resistance while maintaining impact strength in the core.

The versatility of special steels is evident in their wide range of applications. High Nickel or Molybdenum steels are sought after for wire drawing due to their strength and durability. High Chrome steels are favored for their resistance to corrosion, making them ideal for harsh working environments.

Virat Special Steels‘ commitment to providing a comprehensive selection of special steels is a testament to their understanding of the industry’s evolving needs. Whether it’s for wire drawing, resisting corrosion, or other specialized applications, they have a steel for every purpose.

Special Steels Supplier in NOIDA, The industrial landscape of NOIDA and Greater NOIDA continues to thrive, thanks in part to the availability and quality of special steels. As industries push the boundaries of innovation, the demand for specialized materials that offer superior performance and durability will only increase. Companies like Virat Special Steels are not just suppliers; they are enablers of industrial progress and contributors to the economic vitality of the region.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

Let Virat Special Steels be your trusted partner in driving industrial growth in the Noida and Greater Noida region.

For more information visit:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-noida/

Contact us today to discuss your special steel needs and how we can help propel your projects forward!

📞+91-98140 21775 🌐www.viratsteels.com 📩 info@viratsteels.com

Stay connected with VIRAT SPECIAL STEEL!

Want to stay ahead of the curve in the steel industry? 🏗️

Join our #WhatsApp channel today and get real-time updates, exclusive insights, and the latest on our offerings straight to your phone!

WhatsApp channel Virat Steel

Virat Special Steels, INDIA ! …

Get in touch with us today to place your requirement !

The company maintains the biggest Steel Yards and holds a high level of inventory of Special Steels like … #DIN2714, #DB6, #H13, #H11, Tool Steels, Die Steels, Special Steels, and Alloy Steels in various grades.

Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List

- DIE STEEL ( HH 370 – 410 BHN ) (DIN-1.2714 / AISI L6 )

- HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

- PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

- HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

- HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

- ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteel.in/special-steel-supply-networks/

Watch now:

https://www.youtube.com/watch?v=c4h5KqyzVd0

📲Don’t miss out on a beat – Click the link in our bio to join now! 🤝 WhatsApp channel of Virat Steel https://whatsapp.com/channel/0029VaW1wyUBKfhy3Nz6aa0h

Any further queries feel free to contact us:

🌐www.viratsteels.com 📬 info@viratsteels.com 📲+91-98140 21775

Trusted Tool and Die Steel Supplier in Rohtak, Haryana!

Rohtak, a city within the National Capital Region of Delhi, stands as a testament to India’s rapid industrial growth. Established in 1976, this planned city has burgeoned into an industrial powerhouse, hosting a myriad of multinational corporations and startups across diverse sectors. With a modest population of approximately 23,000, Rohtak covers an area of 124 square kilometers and is strategically positioned in the Gurugram district of Haryana.

The city’s industrial landscape is particularly notable for its concentration of tool and die steel industries. Tool and die steel are specialized materials crafted to withstand the rigors of manufacturing tools, dies, molds, and other components essential for shaping and molding materials like metal, plastic, and rubber. These high-precision instruments are the backbone of manufacturing, enabling the production of intricate parts with consistency and quality.

Among the prominent players in Rohtak’s steel industry is Virat Special Steels Pvt. Limited. This company has carved a niche for itself by dealing in a comprehensive range of steels, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their commitment to quality is evident in their value-added services, which encompass material machining, provision of cut pieces, and the supply of tailor-made material solutions. Furthermore, Virat Special Steels Pvt. Limited extends metallurgical advice and ensures stringent quality assurance, underpinning their reputation as a reliable supplier.

The company’s state-of-the-art facilities in Gurugram and Ludhiana underscore their technological prowess, while a robust distribution network across India signifies their logistical competence. Such attributes not only enhance their standing in Rohtak’s industrial domain but also contribute significantly to the region’s economic vitality.

Here are some details about Virat Special Steels:

Company Overview: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made material.

Product Range:

- Die Steel (HH 370 – 410 BHN): This includes grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

Quality Assurance and Facilities:

Virat Special Steels boasts an impressive fully equipped quality assurance and process examination facility.

This includes:

- A laboratory for analyzing steel through chemical tests and spectrometry.

- Ultrasonic examination and hardness testing on Vickers, Rockwell, and Brinell scales.

These facilities allow clients to select the most appropriate type of steel for their specific applications and optimize costs in the long run.

Make In INDIA:

Virat Special Steels offers “Make In INDIA” products at competitive prices, great quality, and prompt servicing. They aim to increase and improve CPC (Cost Per Component) for their customers.

Rohtak’s evolution from a nascent city to an industrial hub is a narrative of vision, planning, and execution. The city’s tool and die steel sector is a microcosm of this transformation, reflecting the synergy between industrial expertise and infrastructural development. As Rohtak continues to expand and diversify, its role in India’s industrial narrative remains pivotal, promising a future where innovation and growth go hand in hand.

For more information, you can explore here:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-rohtak/

Any further queries feel free to contact us :

☎ +91 98140-21775 🌐https://www.viratsteels.com/

📬 info@viratsteels.com

The Evolution of Steel, a look at the Last 20 Years!

Steel, an alloy of iron and carbon, has been a fundamental building block of modern civilization. Its versatility and strength have made it a material of choice for a myriad of applications, from construction to automotive manufacturing. However, the steel industry is not static; it has undergone significant changes over the past two decades, with over 75% of the 3500 steel grades in use today not existing 20 years ago.

Evolution of Steel, a look at the Last 20 Years.

This rapid evolution in steel grades can be attributed to technological advancements and the industry’s response to the increasing demands for higher performance materials. The development of high-strength, high-performance steel structures is a testament to this progress. These new steel grades are designed to meet specific mechanical properties, chemical compositions, and intended uses, catering to more specialized applications than ever before.

The introduction of these advanced steel grades has necessitated revisions in design standards and codes. For instance, the Eurocode , which provides guidelines for the design of steel structures within Europe, is undergoing updates to incorporate the design rules for these new steel grades. This reflects the industry’s commitment to innovation and safety.

The global steel production has also seen a steady increase, reflecting the growth and demand in various sectors. This growth is supported by the continuous development of steel grades, which has been crucial in meeting the challenges of modern engineering and construction.

The history of steel itself is a fascinating journey from its early beginnings to the modern standards we see today. The mid-20th century marked the need for more specialized steel products, leading to the development of the modern steel grades we are familiar with. This evolution has been driven by the addition of different elements in varying amounts, allowing the material to be tailored for specific applications and industries.

For those interested in exploring this topic further, the article “Implementation of high-strength, high-performance steel structures” provides an in-depth look at the current state and future prospects of steel grades in the construction industry. It is a valuable resource for understanding how the steel industry has adapted to the changing needs of the world.

The evolution of steel grades over the past 20 years is a clear indicator of the industry’s ability to innovate and adapt. It is a story of progress, one that continues to unfold as we push the boundaries of what this essential material can achieve.

The study delves into the value of reestablishing compositional information for steel recycling and sheds light on the dynamic nature of steel grades.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA

Your Trusted Partner in Special Steels. Explore a vast inventory of Die Blocks and Tool Steels sourced from renowned manufacturers worldwide…

Our Steel Yards boast a comprehensive inventory, including:

- DIE STEELS (DIN-1.2714)

- HOT WORK STEELS (H-11, H-13, DB6, DIN 1.2714)

- COLD WORK STEELS (HCHCr, D-2, D-3, DIN 2379, DIN 2080)

- HIGH SPEED STEELS (M-2, M-35, T-1)

- PLASTIC MOULD STEELS (P-20, DIN 2738)

- ALLOY STEELS (EN-SERIES)

Learn more :

https://www.viratsteels.com/

Any queries feel free to contact us : info@viratsteels.com or

Call on mobile number +91-9814021775

Are you looking for trusted Tool and Die Steel Supplier in Indore?

Indore, the bustling city in the heart of Madhya Pradesh, India, is a blend of rich cultural heritage and industrial prowess. Founded in 1715, Indore’s history is deeply intertwined with the Maratha Holkars, serving as the capital of their princely state and later as the summer capital of Madhya Bharat state. Today, Indore stands as a testament to its past while forging a path as a major industrial and educational center.

Tool and Die Steel Supplier in Indore

The city’s industrial landscape is diverse, with a significant presence in the tool and die steel sector. These industries are crucial for supporting various other sectors, including automotive, aerospace, and medical industries, by manufacturing and supplying essential tools, dies, molds, and components. The growth of these industries reflects Indore’s commitment to development and innovation.

One notable company contributing to this industrial segment is Virat Special Steels Pvt. Limited. With a focus on a wide range of specialized steels, they cater to the demanding needs of modern industries. Their services extend beyond supply, offering material machining, custom cut pieces, and metallurgical advice, ensuring that clients receive not just products but complete solutions.

Virat Special Steels exemplifies the industrial spirit of Indore, showcasing the city’s ability to adapt and thrive in the ever-evolving economic landscape. Their state-of-the-art facilities in Gurugram and Ludhiana, coupled with a robust distribution network, underline their commitment to quality and customer satisfaction.

If you’re looking for a Tool & Die Steel supplier in Indore, I recommend checking out Virat Special Steels Pvt. Limited. They are one of the best suppliers in the city, offering a wide range of steel products for various industrial applications.

Here are some details about Virat Special Steels:

Company Overview: Virat Special Steels deals in all kinds of tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. They provide value-added services such as material machining, cut pieces, and tailor-made material.

Product Range:

- Die Steel (HH 370 – 410 BHN): This includes grades like DB6, DIN-1.2714, and AISI L6.

- Hot Work Steels: Grades like DIN 2343 and 2344, as well as AISI H11 and H13.

- Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

- High-Speed Steels: Including DIN 3243, 3343, AISI M2, and M35.

- Cold Work Steels (HCHCr): Grades like DIN 2379, 2080, and AISI D2, D3.

- Alloy Steels (EN-Series) and more.

Quality Assurance and Facilities:

Virat Special Steels boasts an impressive fully equipped quality assurance and process examination facility. This includes:

- A laboratory for analyzing steel through chemical tests and spectrometry.

- Ultrasonic examination and hardness testing on Vickers, Rockwell, and Brinell scales.

These facilities allow clients to select the most appropriate type of steel for their specific applications and optimize costs in the long run.

Make In INDIA:

Virat Special Steels offers “Make In INDIA” products at competitive prices, great quality, and prompt servicing. They aim to increase and improve CPC (Cost Per Component) for their customers.

Any further queries feel free to contact us :

☎ +91 98140-21775 🌐https://www.viratsteels.com

📬 info@viratsteels.com